Message from the editors

So, is the hype real? In my opinion, we are on the verge of the next steps in additive manufacturing. Companies are investigating automation possibilities, high-speed production, and the inclusion of post-processing of AM parts within their process chains.

Featured

The future of additive manufacturing

What is the future for AM technology,beyond incremental developments

that will influence new manufacturing applications?

Automated Additive Manufacturing

The importance of connecting AM to allow for integration into the overall production system, resulting into the mapping of the physical world to the digital world.

Lessons Learned

What is AMII?

Additive manufacturing can offer a wide range of potential benefits for your production, such as increased manufacturing flexibility and improved functional testing capabilities. Discover how you can unlock these benefits.

Beyond a name

Personalised marketing gives companies the opportunity to build trust and expand their reach through engaging content. Here’s what that means to manufacturers.

Building the Future Together

Learn how TValley intents to identify, develop, and implement new, industry driven

innovations in the field of robotics and mechatronics.

Technology & Innovation

Towards automated match production using WAAM

In the recent years, significant effort is being put in developing Wire +Arc Additive Manufacturing (WAAM). Learn how the multi-faceted challenges in the process, materials and design of WAAM parts was tackled.

When & who does industrial additive manufacturing pay off?

There is a serious boom in the branch of additive technologies. The possibility of faster production and independence from supply chain is benefiting across industries.

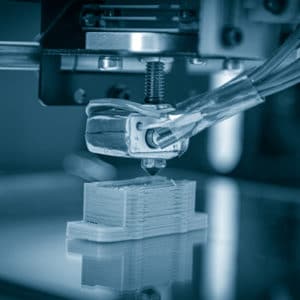

A New Phase in Professional 3D Printing

Thanks to 3D printing, a design can easily be adapted to the customer’s requirements and technology. The technology makes it possible to produce parts on-demand and it is the method to easily develop prototypes.

3D Concrete Printing

New materials and technologies are becoming accessible at a rapid pace. But how does one develop innovative products with them?

High Performance and Sustainability

How aluminium alloys for metal additive manufacturing processes will boost additive manufacturing applications.

How Bond3D is unlocking the full potential of peek for 3D printing

Leveraging innovative new additive manufacturing processes, Bond3D helps businesses build better products in less time and at reduced overheads.

Printing the start of our journey to the shopfloor

To mark an important milestone, FIP-AM@UT in partnership with In Summa Innovation, created a 3D-printed titanium alloy brick as a symbolise of their shopfloor in driving innovation across the region’s manufacturing sector.

How to get the best of both worlds

When TT Engineering talk about Personalised Manufacturing, their focus is on delivering quality. In the sense of being the best in translating their customers demand into a good, functional product. Learn how they do this.

AMC NU

Advanced Manufacturing Program

Find out what existing and potential projects are being explored by FIP-AM@UT.

Sustainability

Lifecycle Assessment

Manufacturers face growing regulatory, societal, and business pressure to adopt sustainable production practices, hence the need for a better way to gain insights into the impacts of production processes. A lifecycle assessment facilitates transparent and credible environmental accounting, typically throughout the entire lifecycle of a product.