A new phase in professional 3D printing

Thanks to 3D printing, a design can easily be adapted to the customer’s requirements and technology. 3D Printing (Additive Manufacturing) makes it possible to produce parts on-demand and it is the method to easily develop prototypes.

3D printing can be used in all kinds of industries and markets and for countless applications. Think of manufacturers of machine parts, car parts, medical equipment and household appliances, among other things. The digital inventory simplifies supply chain management, eliminating the need for expensive warehouse storage. 3D printing also saves time and money.

3D printing is production on demand

The main advantage of 3D printing is being able to produce on demand, while controlling storage and supply chain management. By 3D printing spare parts, for example, it is possible to develop a new warehouse system that works better and more efficiently. At manufacturers of parts and spare parts, a stock of spare parts will eventually arise. These can take up a lot of space and in the worst case, this stock can even age. A physical inventory is often still preferred, while a digital inventory offers a perfect solution. Digital inventory becomes very easy by producing parts on demand with 3D printing. The spare parts do not require physical storage, but can be printed on demand when necessary. This is suitable for single pieces, but also for small batches and series. All that is needed is a suitable file for 3D printing. The use of additive manufacturing also offers an opportunity to adjust the design of a product in the meantime.

Prototyping or series production?

3D printing has little or no start-up costs, which makes producing a few pieces very interesting. Certainly in comparison with conventional production techniques, for which tooling and moulds are required.3D printing is therefore the method for prototyping and very suitable for optimizing a design. Is the design suitable? Then with 3D printing it is easy to start a series production.

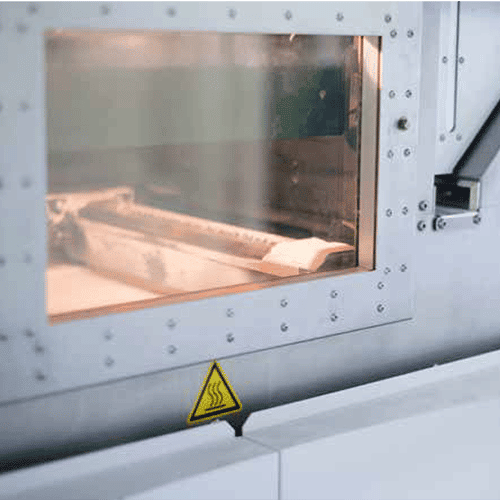

3D printing for agri & food

One of the recent developments is 3D printing for the food industry and agri-sector. The choice for 3D printing within these sectors therefore offers plenty of advantages. Think of design freedom, the production of custom parts and the manufacture of complex or organic shapes. This is particularly attractive for food-related applications. It also enables small stocks and ensures rapid development from prototype to functional parts. Some applications of 3D printing within the agri- and food industry are grippers, nozzles, machine parts, prototypes, robots and drones.

EC 1935/2004

To deliver a food-safe 3D printed product, the material must be suitable according to the requirements of EC 1935/2004 and produced in accordance with the EC Directive 2023/2006 (Good Manufacturing Process).

Oceanz’s 3D printing processes comply with these regulations; the processes are included in the quality system and have been validated by external accredited parties. The material (plastic and metal) is therefore safe for production for consumption purposes or may come into contact with food. If desired, tests can be carried out for specific raw materials or circumstances (such as temperature and raw material).

Oceanz 3D printing is ISO 9001, ISO 13485 (medisch) en EC1935/2004 (food grade) gecertificeerd.

Direct local 3D printing?

Direct online ordering is possible via YourOceanz.eu. Oceanz offers you a wide choice of 3D printing material (plastic and metal) and after treatments. After ordering, you will quickly receive the 3D printed products. The 3D printing is done locally in the Netherlands.

The quality policy is an important part of our company policy. Oceanz attaches great importance to high quality, but also to the continuous improvement of the quality of the products and internal processes. These are secured by skilled personnel in combination with innovative machines and ERP solutions. In addition, the choice of material is also important. Within this framework, there are a number of directives and regulations within the EU. Oceanz is ISO 9001, ISO 13485 (medical) and EC1935/2004 (food grade) certified.

More info: www.oceanz.eu/en/

Oceanz 3D Printing is a professional 3D printing company and has been familiar with the market, industry peers and professionals for years. With acquired knowledge and concrete business cases, Oceanz has gained plenty of experience in various sectors, including Industry, Agri & Food, the Medical field, Automotive and Aerospace. Together with our customers, we develop and create 3D printing innovations that make the difference in every production process. The result: cost savings, reduction of failure costs and increasing production capacity.