Printing the start of our journey to the shop floor

in April 2022, the Fraunhofer Innovation Platform for Advanced Manufacturing at the University of Twente (FIP-AM@UT) celebrated the launch of the construction phase of its new offices and shop floor facilities as part of the growing Kennispark industrial community in Enschede. Once complete, the premises will become the new home for the FIP- AM. The new complex will provide ample space for up to 50 employees and is expected to be completed by the end of the year.

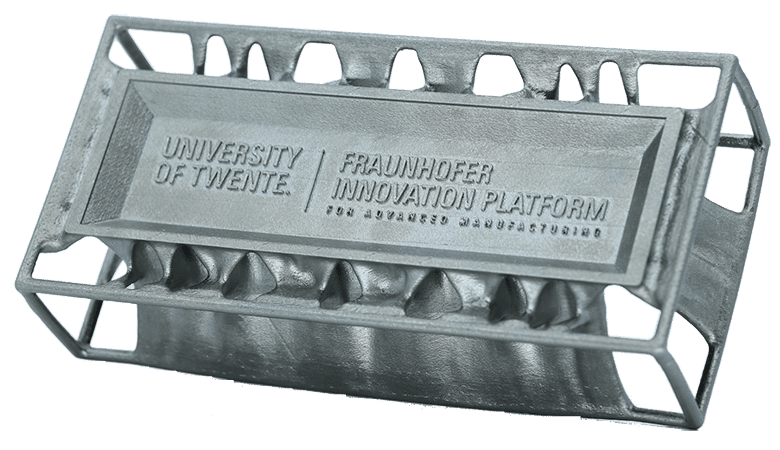

To mark this important milestone, the FIP-AM wanted to create something to symbolise its role in driving innovation across the region’s manufacturing sector. In partnership with Dutch engineering consulting firm In Summa Innovation, engineers at FIP-AM designed and created a 3D-printed brick made of titanium alloy to place within the new building as a reminder of their vision for creating a highly advanced and modern shop floor.

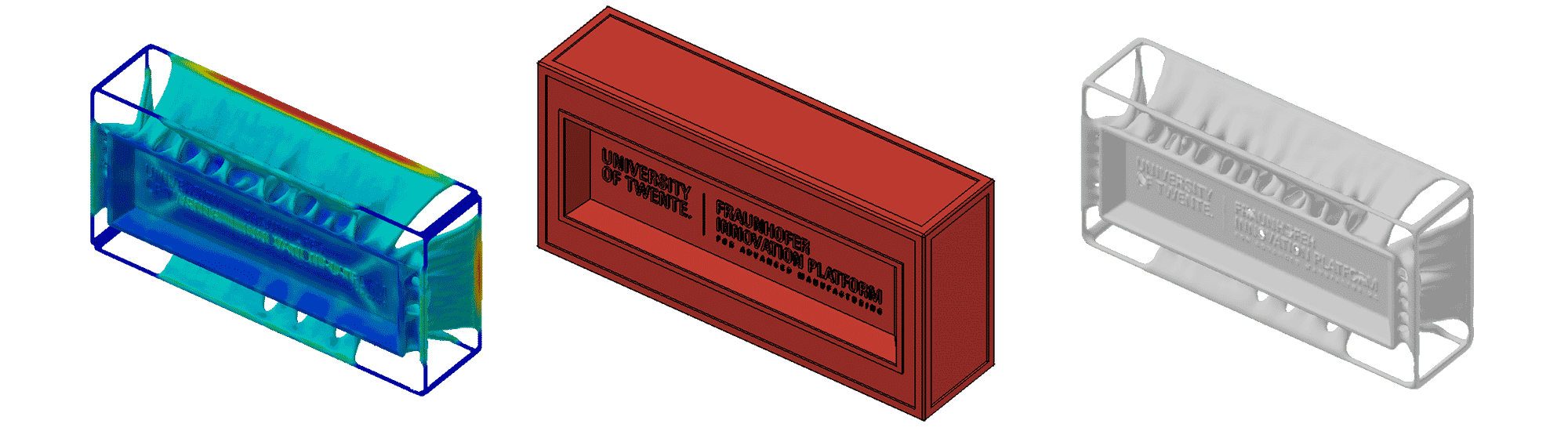

The FIP-AM used their MetalFab1 metal additive manufacturing machine to print the brick using high-tech materials. Designing the brick was a critical part of the process, since it included an advanced latticework structure that would ordinarily be very challenging to print using traditional manufacturing techniques. First attempts at building the brick in the machine presented some unexpected problems. In particular, creating lattices inside the machine proved time-consuming and complicated, requiring multiple sessions of numerical modelling and testing.

Fortunately, thanks to their cooperation with In Summa, the FIP-AM managed to create an optimised design using Hexagon’s MSC Apex Generative Design platform. Apex GD is a leading additive manufacturing solution for designing high-precision industrial components, such as ones used in the aerospace, automotive, machinery, consumer products and medical sectors. The software reduces the time it takes to design components and export their geometry directly to 3D printing machines, all without compromising on output quality.

The FIP-AM’s additive manufacturing specialists Angus Fitzpatrick and Sikander Naseem worked with Noël Bijl and Gökhan Tintin from In Summa to provide the key parameters for the design to generate a result in just a few hours. In record time, the brick design was ready for printing, though they also wanted to make sure that the end result would be right the first time in order to meet the time constraints. In addition to creating a novel and striking design, the larger but more distantly spaced struts designed in Apex GD were easier to print without compromising on strength.

The brick will be housed in the new FIP- AM building to symbolise its state-of-the- art nature. Once completed, the facility will be home to some of the world’s most advanced manufacturing technologies and concepts, along with up-to-the- minute production systems. The ultimate goal is to create an optimised environment for demonstrating Industry 4.0 in action.

The new location itself is also symbolic. Located directly across from the main entrance to the Twente University campus, it clearly shows that the FIP-AM is still an integral part of the university, whilst also connecting with the broader manufacturing sectors of the Netherlands and beyond.