A common problem in steel-product manufacturing is the significantly high throughput time of steel products in comparison to the sum of their process times. Manufacturers have similar production methods which, upon investigation, are likely to yield improved time efficiency resulting in a higher relative touch time per product. To lower production times, it would be optimal to introduce production planning with higher levels of dynamicity, granularity and detail.

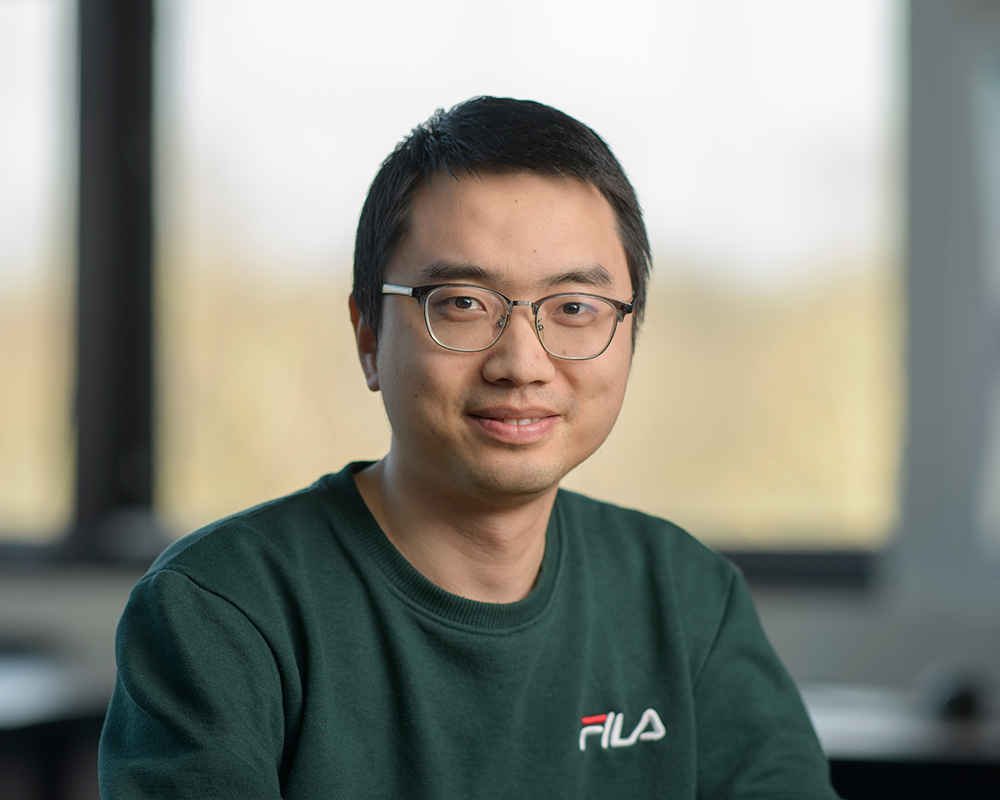

KORT is a project working towards developing a proof-of-concept solution that can reliably forecast turnaround times. This is achieved by influencing the waiting time of products through detailed production planning. The focus of this project will lie in determining the factors that influence throughput time and identifying opportunities to manipulate them. It will help to recognise and categorise the similarities our industry partners possess, based upon their physical and digital infrastructure.

This will form the backbone of a decision model which will steer the planning process more accurately. Historical and real-time ERP data is used to develop a modular framework that supports detailed and flexible production planning, resulting in a new, robust planning and control solution. We can then use this demonstrator as a new industry standard, or an object lesson to guide steel-product manufacturers when adjusting and/or improving their production planning.