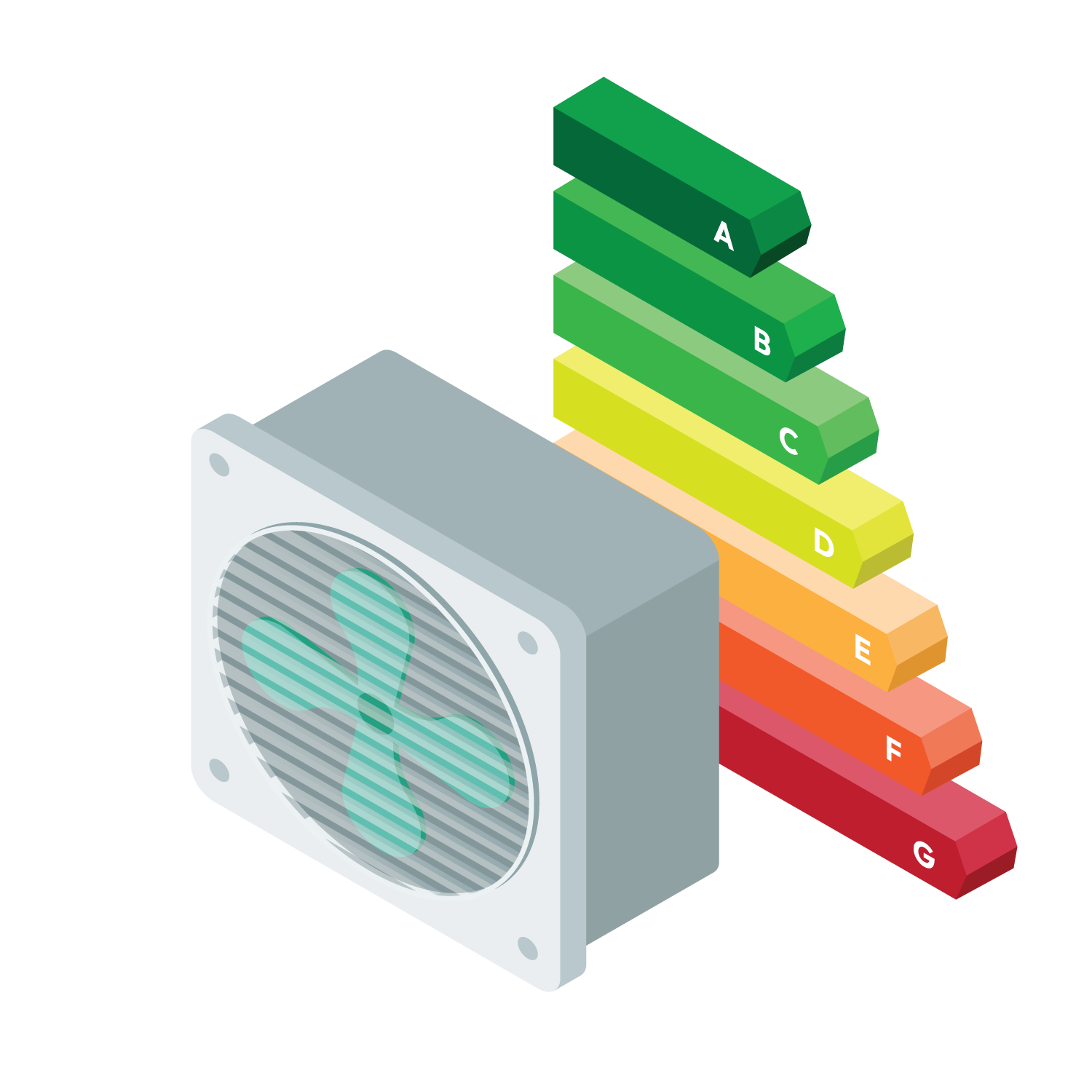

In the fight against global warming, people are continuously looking for sustainable alternatives for central heating systems. Heat pumps offer an ideal solution by reducing reliance on fossil fuels like natural gas and lowering monthly gas bills for households amid soaring costs.

Over the past decades, countless initiatives have been raised in the global quest to a more sustainable lifestyle of the world population and the preservation of nature. An essential percentage of greenhouse gas emissions, that rapidly increase global warming, stem from central heating systems in households. Therefore, governments take steps towards planning and implementing modern, clean – hence sustainable, heating infrastructures. One of the solutions for cleaner heating of buildings is a heat pump. By extracting heat from the environment and redirecting it, these pumps constitute one of the most eco-friendly central heating systems in homes, shops, schools, and offices.

The SuperHybrid heat pump as developed by Cooll Sustainable Energy Solutions, an SME spin-off company of the University of Twente, is a rather unique example of this. This heat pump functions as a direct replacement of natural gas heating. Whereas conventional heat pumps device an electrical-mechanical compressor in the compression of the refrigerant, Cooll’s SuperHybrid uses a heat-driven adsorption compressor to this end. The SuperHybrid is powered by gas and extracts heat from the outside air, directly saving 30% on gas and CO2 emissions. With green gas or hydrogen applied as fuel, emissions can be reduced even further.

To meet the rapidly increasing demand, Cooll is working together with the FIP-AM@UT to make their product ready for an upscaled production. The heat pumps devise a thermal separation unit to separate the hot and cold pipes and prevent mixing. The current piping layout creates challenges when upscaling the production of the system, due to a complex geometry. This results in a relatively long and delicate manufacturing process. The goal of the project is to redesign this assembly by considering several manufacturing methods, material selection, and suitable joining techniques. The focus of this project will be more efficient production operations by simplifying the design, without affecting the performance of the heat pump.