Evolving manufacturing paradigms

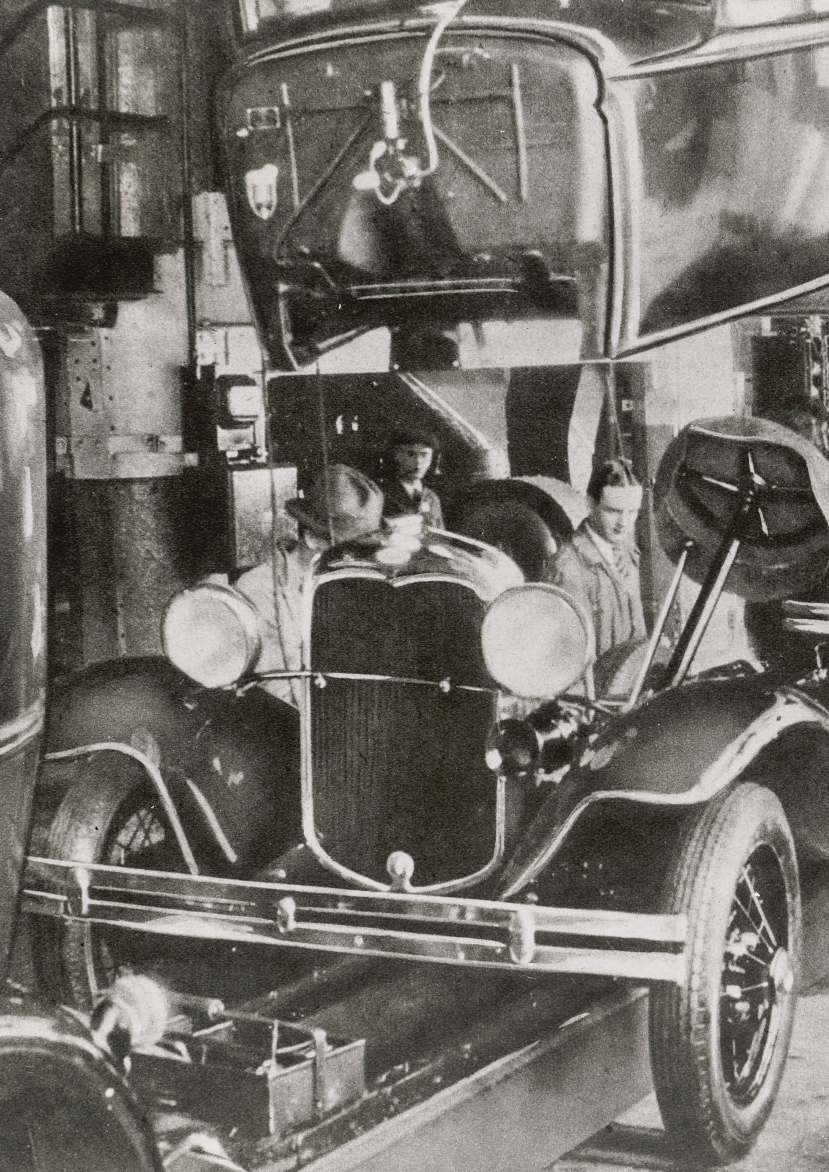

Since manufacturing erose two centuries ago, it has evolved through several paradigms from Craft Production over Mass Production to Lean manufacturing and Mass Customization, addressing the needs of market and society. Craft Production as the first paradigm focused on creating the product that the customer requested. This resulted in unique products, with a high product variety and flexibility. However, the costs of these products were relatively high, since no manufacturing systems were associated with this paradigm. In the 1910s, Mass Production enabled the making of products at lower cost through the production of large volumes with limited variety all enabled by dedicated manufacturing systems. A symbol for Mass Production was Henry Ford’s moving assembly line and his statement: “Any customer can have a car painted any color that he wants so long as it is black”.

After the end of World War II, demands for products were very high, and the paradigm of Lean Manufacturing emerged as a necessity due to limited resources in Japan. Its manufacturing management philosophy focuses on minimizing all kinds of waste while maximizing customer value, and is still an important factor of all modern production systems. In the late 1980s, Mass Customization emerged as a response to the demand of consumers for higher product variety. Manufacturers started offering certain variations to standardized products. Especially in the automotive industry, an enormous product variety has been achieved. Nowadays, almost every industrial sector can offer high product variety to heterogeneous markets around the globe.

Manufacturing industries can now see a new trend going even beyond mass customization towards highly personalized production. These products cannot be manufactured the same way and will require different work steps and cycle times. Therefore, they cannot be efficiently produced in production lines with static tact times. Instead it is important, that – in the extreme case – lot size one can be manufactured under the same economical parameters as in large scale production systems although the production system’s flexibility is much higher.

Flexible Production

As a result of the aforementioned diversifications, an innovative, flexible and calable production system that can deal with altering demands and uncertainties has become a necessity in future production systems. Since the product is a result from evoked demands, and the production correlates to the product, the production system – in the end – is linked with the demand. Due to expensive investments in production a flexible mixed-model production is required which can deal with:

- Product diversity

- Keeping a high output level simultaneously

- Uncertainties in respect to future demands

- Long term design and development

- Increasing use of new technologies

Hence, future production systems should provide a high ability for flexibility. In this context flexibility can be classified as follows:

- Market flexibility (The ability to adapt to changing market demands)

- Production flexibility (The range of diverse products a system currently can produce)

- Volume flexibility (scalability)

- Product flexibility (The ability to implement new products or change the current set of products)

- Process flexibility (The ability to reconfigure the production system)

Considering the main issues as above, a progression of product flexibility that simultaneously renders mass customization will be the main objective in the production industry. If time variable trends and connected fluctuations in consumer demands are additionally considered the product system also has to be flexible in volumes. This means the ability to scale the output in short terms for economic reasons. In long term the system must be able to adapt to market conditions by increasing product flexibility. This is of utmost significance in the above commented accelerating market cycles. Production flexibility, volume flexibility as well as product flexibility are all based on the ability to readjust or reconfigure existing processes. Vital demand on any innovative production system for the future will be process flexibility combined with keeping a high output level as well as a high line utilization rate at the same time.

Matrix Production

One way to achieve this target is by applying the principle of matrix production. This approach towards a resilient, cross-technology system is a combination of technologies and methods from production engineering and Artificial Intelligence (AI). The adaptive design of plant configurations and process chains derived from this can automatically switch “on the fly” to changing product types, resulting in cycle-independent flow production. The linking of several different stations, combines the economic advantages of classic flow production with the flexibility advantage of make-to-order production.

The matrix production opens up new degrees of freedom for the design, planning and control of the manufacturing system for the economic production of high volumes with simultaneous variant flexibility and volume scalability. The potential dynamic redistribution of order tasks to stations in case of changes in customer requirements or failures enables resilient production in a volatile environment. The autonomous control of the factory through an orchestration of AI modules eliminates cycle time differences and thus enables the use of synergy effects.

For enabling matrix production four interacting elements need to be considered:

1. Flexible, cross-technology production cells

2. Order control in the matrix

3. Logistic linkage

4. Digital data and model backbone

The use of reconfigurable manufacturing cells – either fully automated, a manual workplace, or a hybrid cell – enables process-oriented planning of freely linked stations and order allocation based on free capacities of the stations. Thereby, the stations can be arranged in almost any number on a grid. The production cells are equipped with product-neutral equipment and product-specific basic functionalities and can be individually adapted to the respective task by means of process-specific facilities. This use of redundant and versatile manufacturing and assembly cells enable to focus on processes, their full execution, and aggregation of similar technologies and scopes of work.

Order control includes the design and evaluation of AI submodules and heuristics regarding the prediction of order lead times, transportation requirements, material requirements and reconfiguration requirements. To achieve this, an agent-based control algorithm based on reinforcement learning (RL) is developed and integrated into the production planning process. The inclusion or exclusion of further cells in the process without interrupting the value chain, as well as flexible switching to other cells during peaks, implies a plant with variable parts logistics. A key driver of this is the transfer of parts, tools, and semi-finished products to the manufacturing cell using Automated Guided Vehicles (AGVs). Different components or tools are picked up and transported by individually configurable load handling devices (LAM) and navigation to the individual cells is performed by a SLAM navigation algorithm.

The associated higher volatility of shoring location, quantity and timing as an effect of matrix production implies the collection and use of a large amount of high-quality data and the digital linking of all sections. Therefore, a digital representative as backbone for adaptive planning and control is used to increase the value creation process. In particular, agile and resource-optimised control of material, control and information flows requires logistics to be logically linked to production. Not solely for order handling, but also for reconfiguration requirements.

Conclusion

The manufacturing industry always has been a source of innovation and development, with factories adopting new challenges and trends. Over the last two centuries, this resulted in several changes of manufacturing paradigms. Todays and future factories also face several evolving trends like customer demanding for highly personalised products, and an increase in product variety and complexity. As a result, large numbers of different specialised variants of products and components must be manufactured and assembled. Therefore, it is of great importance to achieve a flexible and scalable production system that can coop with high volume. Traditional assembly line concepts, however, struggle to maintain high utilisation rates when producing components with a wide range of processing times on the same line. Hence, alternative configurations are demanded. Matrix production might be the solution, since it enables the requested productivity/efficiency but also variant and volume flexibility. In combination with flexible transportation systems and a control system, high utilisation of the work cells is obtained. This resolves the discrepancies between flexibility and efficiency and allow for the application of more flexible production systems by adequate factory perspectives