MAINTENANCE: THE WAY FORWARD

Maintenance engineering has always had one core objective: to reduce and ideally eliminate the downtime of equipment in the pursuit of operational efficiencies. However, the way we approach maintenance is changing due to the emergence and diffusion of digitalised technology and smart sensors.

The competitive nature of today’s economy sees equipment downtime due to maintenance as a core aspect of manufacturing that must be managed effectively to remain efficient and competitive. In many highly competitive industries, preventative maintenance is critical to avoid expensive downtimes and equipment damage.

Traditional maintenance engineering saw reactive approaches accepted as the status quo; in simple words, we waited for a failure before we replaced or repaired the damaged part or system. In the last decades of the past century, there have been relevant developments in the way to approach this situation, introducing predictive maintenance solutions , with manufacturers looking at reducing down-time to drive efficiencies and performance.

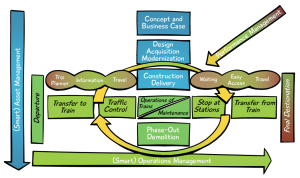

The overlap between asset management and operations

management for a passenger transport company is shown below

On the vertical axis the life cycle of the conveyance is shown: from concept and business case, via acquisition, design, construction and delivery to actual operation

including maintenance and subsequently decommissioning.

The customer experience is represented on the horizontal axis: departure from location, transport to station, traffic management, driving and stopping the train and subsequent transport to destination. The customer experience mostly concerns information, travel and visiting.

Routine manual inspections and strategy-based approaches can still assist in creating statistics-based predictive maintenance plans and models that were traditionally based on existing reactive maintenance operations. However, these activities are still susceptible to low-occurrence failures, and unplanned failure events that can cause major issues in a manufacturing production line.

With the emergence of affordable sensor technologies, factory floors are becoming more interconnected and allowing maintenance engineers to use digital technology with networked equipment and infrastructure to develop better strategies when it comes to keep a system or piece of equipment producing.

Where prediction used to be based on past collected data, new technology allows real-time live data to be collected and used to keep systems functional and operational, bringing closer and closer “smart” asset management and “smart” operation management With the emergence of affordable sensor technologies, factory floors are becoming much smarter and allowing maintenance engineers to use digital technology with networked equipment and infrastructure to develop better strategies when it comes to keeping a system or piece of equipment producing.

At the intersection between Asset Management and Operation Management, the available digital information and equipment facilitate the operational management at strategic, tactical and operational levels. Data on the product, the operational production processes and the condition of the assets are the main drivers. Efficiency and effectiveness can be enhanced by also linking smart asset management and smart operations management properly from a digital point of view. Performance management takes place at this intersection. The adding value is that this structure brings the longer-term strategy and the short cyclical operational processes closer together.

Three main advancements in technology and innovation are driving the transition towards a new form of maintenance:

- Internet of Things (IoT)

- Sensors Integrated Networking Technology

- Digital Twin

Manufacturing process flows, along with their associated plant and equipment are becoming more integrated and network connected thanks to digitised technologies. To enable companywide digitisation, new (and old) equipment is often fitted with advanced digital sensors that can provide operational data to operators and management.

Through sensor embedded networks, we see huge potential for change in the way maintenance engineering is undertaken. Predictive maintenance is able now to be facilitated by live data from our factory floors and built environments.

Some industries, such as energy, mining, aerospace and defence, are already seeing major benefits and leading the way in developing the future of these new maintenance systems.

A large part of the development drive coming from these industries is the huge overhead costs and safety implications involved if parts, systems or equipment fail unexpectedly or are unavailable for long periods.

What we are now beginning to see is a diffusion beyond these large industries flowing into general manufacturing. No longer the realm of huge enterprises, these sensor-based technologies are becoming very accessible to SMEs and teams who do not have extensive resources and technical knowledge.

A simple example of how this may be applied in a factory environment can be given with a drive motor. Let’s say a motor that drives a machine has built in sensors which can monitor specific physical phenomena. An IoT connected sensor system can trigger a procurement event for a spare motor part in a firm’s enterprise resource planning (ERP) software before downtime or a critical failure occurs. This often allows to completely automate the process of manualcheck equipment condition, and parts’ purchase.

The adoption of real-time condition monitoring, in its more advanced form at least, allows creating a digital copy of the real asset, also called ‘digital twin’. With a live feed of operational and machine data acquired from sensors, the virtual replica can become a very powerful tool to not only understand the actual state of the system but also predict its future state. Considerable savings in time and cost can be made when a factory environment is simulated using operational data from physical equipment to create a closed feedback loop of a system.

Virtual and Augmented Reality and Operator 4.0

When looking at shop floor or field-based applied technology, virtual reality (VR) and augmented reality (AR) technology is set to change the way technicians and field engineers maintain and work on equipment, creating empowered workforces often referred to as ‘Operator 4.0’. With simple and affordable network-connected devices such as tablets or wearables, even a small firm can create tailormade maintenance procedures with virtual guidance and prompts laid over the assembly or equipment that a technician is working on. In its simplest form, an operator can hold the camera of the device up to the equipment which will then provide the overlaid work or maintenance instructions, guiding him or her through the necessary steps or providing accessible live information. This can completely illuminate cumbersome paper-based manuals and rapidly decreases the time to recommission a piece of equipment to operational capacity.

It is predicted that these technologies will become commonplace in future factories, making maintenance operations faster, less prone to human error and allowing for higher performance in maintenance engineering tasks. Many of the technologies discussed here are only in their infancy when it comes to practical application. The future will see endless possibilities for new applications that will improve the way maintenance operations are performed, creating safer factories and reducing the human labour required to perform important but often repetitive tasks.