Boosting industrial growthwith emerging technologies

Energy and Resource management

Together with regional government and partners, the Fraunhofer Project Center (FPC) has developed the Advanced Manufacturing Program (AMP) to establish a transitional framework towards Manufacturing 4.0 and empowering manufacturing industries in the Eastern part of the Netherlands.

The Advanced Manufacturing Program (AMP) provides subsidies through the RegioDeal supported by the Province of Overijssel and the Dutch state. It aims to encourage rapid development of Twente and other regions in the East Netherlands by forming an Advanced Manufacturing hub with an outward looking European image. With this the AMP greatly enhances the region’s reputation and business climate.

Within the AMP, the Fraunhofer Project Center at the University of Twente develops innovation projects around manufacturing technology themes. Every AMP project is built around solid industrial collaboration, empowering companies with relevant knowledge and new technological and industrial methodologies, Through the hub, these can be shared with other high-tech manufacturing industries in the region.

Member companies’ of the AMP can solve their specific technology problems and answer their market-oriented questions. This is achieved by developing and creating demonstrators that offer participating companies direct technological insight. FPC then utilises workshops and master classes to further disseminate this newly acquired knowledge.

Energy and resource management

Current trends from environmental, social and economic perspective force manufacturing companies to improve their energy and resource management. Especially the attention to environmental aspects like global warming or resource depletion is accelerating and different drivers are exerting pressure on companies. Besides more and more political attention and rising public awareness, drivers like increasing energy and raw material prices, potential lack of critical resources, necessary investments for environmental regulations and introduction of CO2 certificates all directly connect environmental driven issues to business objectives of a company.

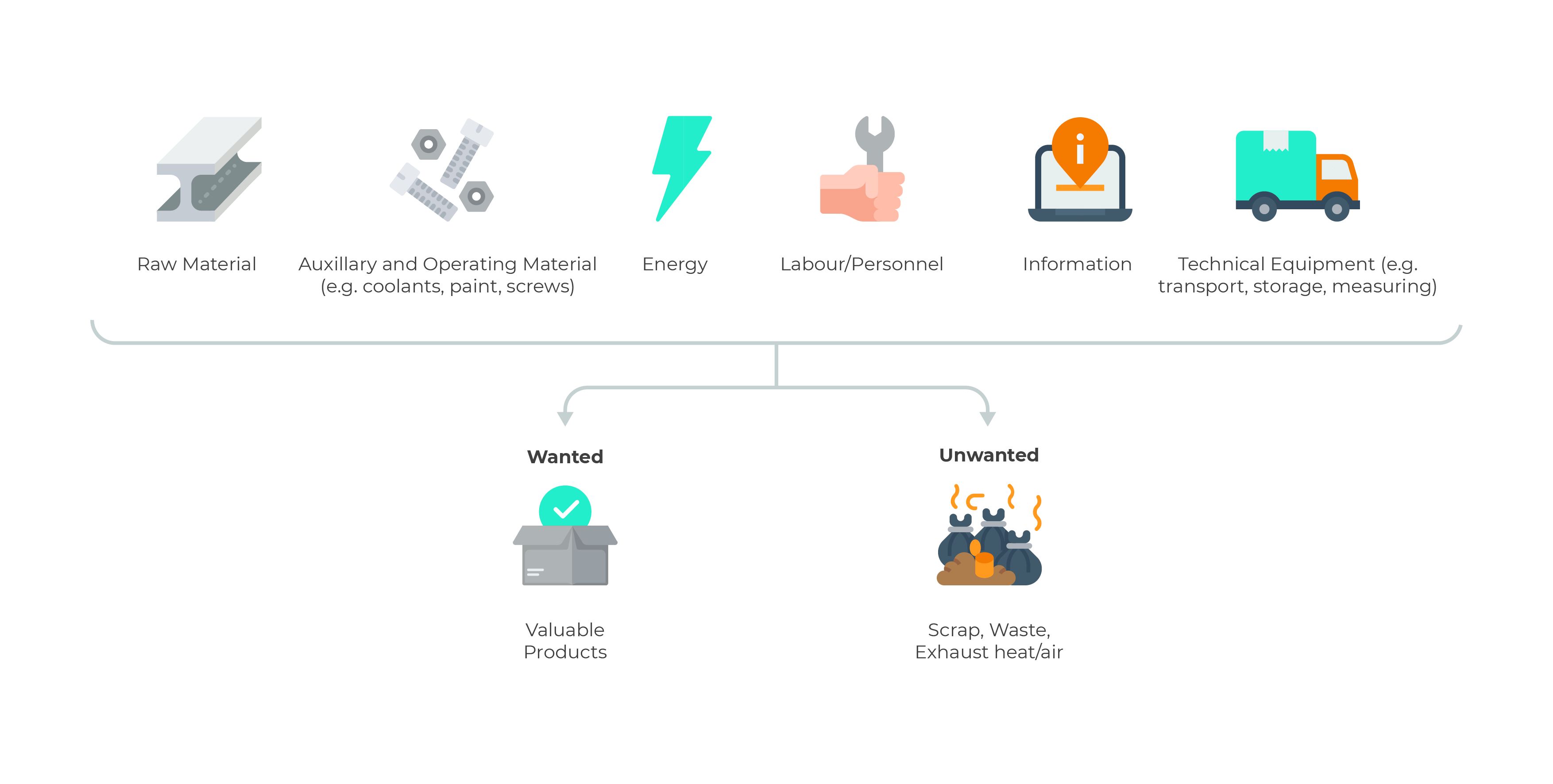

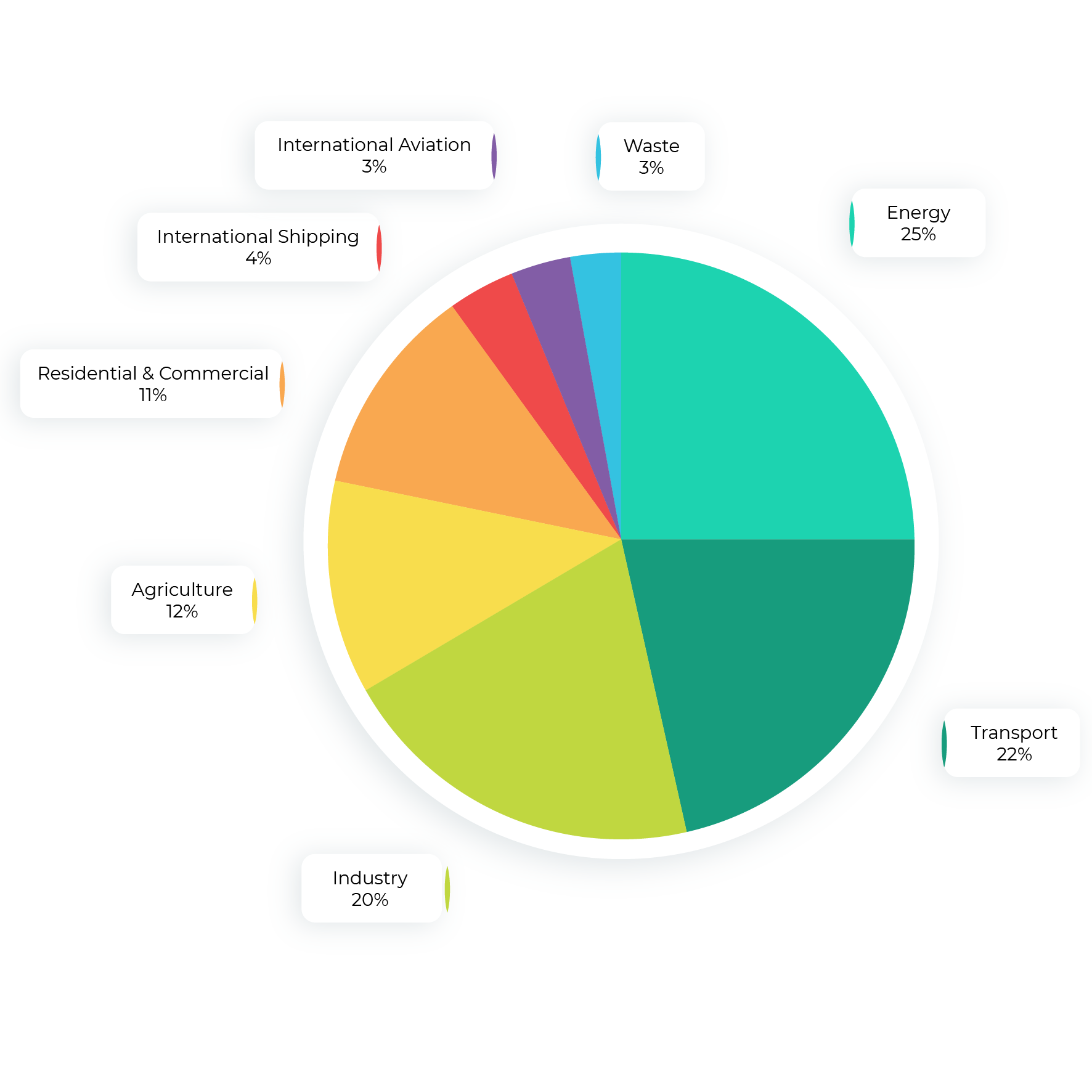

Manufacturing processes have a significant impact on the environment. Energy is used to process raw materials and transform them into products and wanted or unwanted by-products. While one part of the resources is used for creating value and embodied into the form and composition of products, another part is wasted in terms of material losses, heat and emissions. From mining (extractive industry) to the processing of materials (material industry), through manufacturing of discrete products and finally the waste industry: altogether significant quantities of energy are needed which lead to respective energy related emissions. This has resulted in the manufacturing industry being one of the largest energy consumers and greenhouse gas (GHG) emitters in the world. In Europe, the manufacturing sector is responsible for about 26% of the primary energy use and 20% of the annual GHG emissions, of which the material industry plays a leading role [1]. Designing and improving manufacturing systems while advantageously integrating economic, ecological and social goals have become an essential objective in the manufacturing industry.

Figure 1: Production in context of manufacturing is the transformation of inputs into wanted and unwanted outputs.

Figure 2: Annual greenhouse gas emissions in the EU 2019 (European Environment Agency)

Reference framework

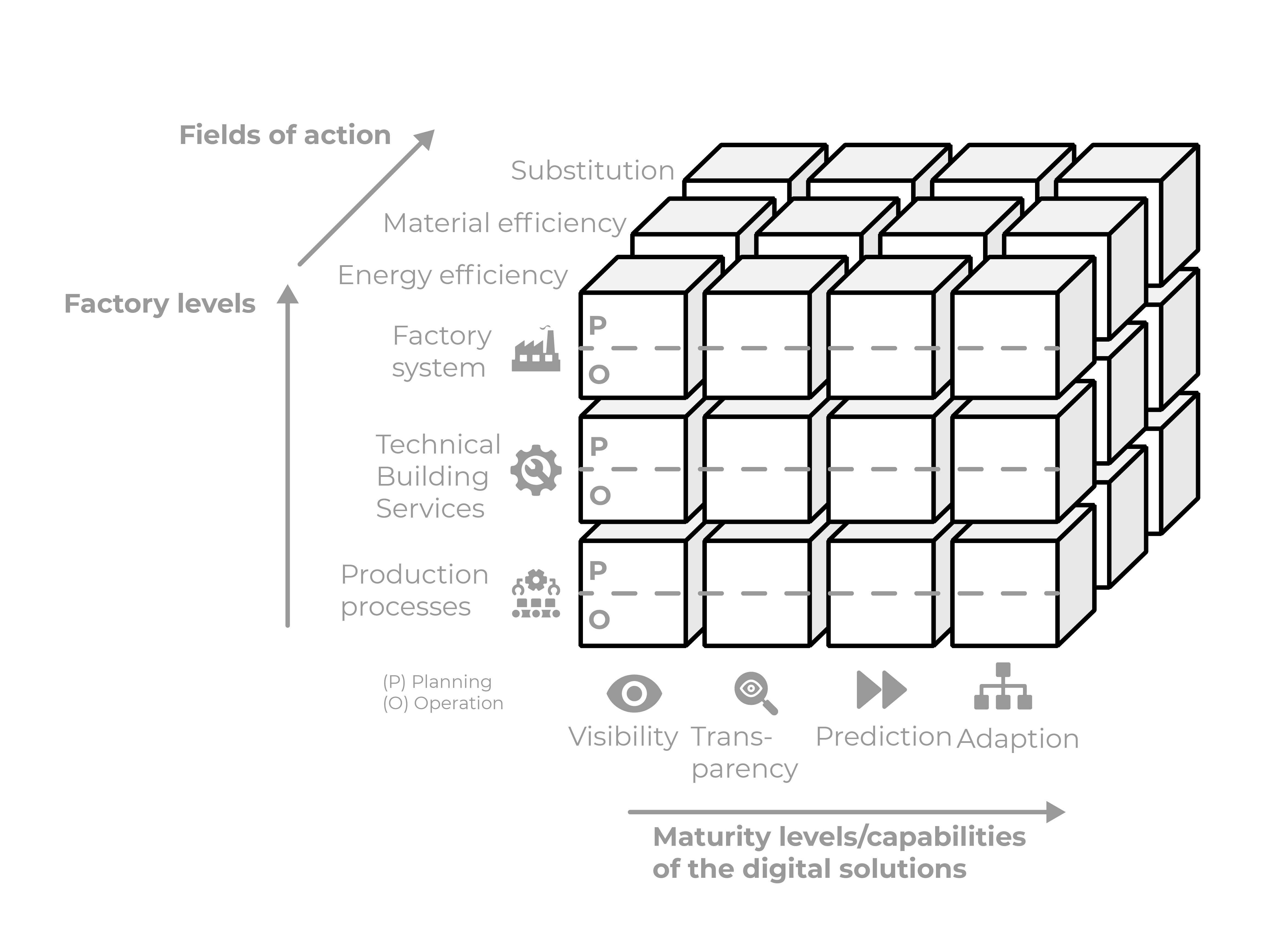

Before we can identify potential fields of actions, we have to consider the reference framework of manufacturing. Industrial activities typically take place within dedicated factories. Factories consist of three subsystems: production equipment, technical building services (for internal energy conversion, providing production conditions like temperature, or humidity) and building shell. Those subsystems are connected through energy, material and information flows. Material flows consist of raw and auxiliary materials, waste streams and (semi-) finished products. In terms of energy, different energy carriers (for example electricity, gas, and compressed air) are externally acquired or internally generated/converted. The information flows allow monitoring and therewith planning and control of operations.

A major change deriver in these flows is the digitalisation of manufacturing industries. Innovative technologies for sensoring, communication, data processing, and visualisation can improve planning and operation of manufacturing. Besides targeting customised production and lowering throughput times, also energy and resources efficiency can be addressed [2,3]. Within Industry 4.0 four different maturity levels can be distinguished, being: visualisation (‘What is happening?’), transparency (‘Why is this happening?’), prediction (‘What will happen?’), and automated adaption (‘How to respond (autonomously)?’) [4]. Higher maturity levels are associated with increasing benefits but also more complexity and efforts. Bringing together those functionalities with the derived fields of action and different factory levels results in the reference framework shown in Figure 3. Within the boxes also the use scenario (planning and operation) is indicated. This framework gives an overview of all combinations and allows a systematic structuring and assessment of digital solutions.

Potential Field of Action

Based on the above mentioned interrelated energy and material flows, three potential fields of action towards more environmentally sustainable manufacturing can be identified (based on [5]):

Digital methods and tools can play an important role towards more energy efficient solutions, both in the planning of production and the support in operation. The former can see major improvements from the selection of the most efficient technologies. Machine learning can be used to systematically identify best practices among production machines or production areas within a company.

More relevant use cases can be found when it comes to support in operation. Based on up to real-time data, parameters of processes (such as temperature setting, or machine speeds) can be adapted.

The substitution to renewable energy sources is a powerful strategy that can significantly reduce the energy related GHG emissions. Besides the production of own renewable energy, the concept of energy flexibility has gained interest by industry. Within that, companies dynamically change their energy demand behaviour depending on the market price and/or the availability of renewable energy. From material perspective, modelling approaches could be used in planning and operation to predict the impact of substitution. For example product related materials but also auxiliary materials, like cutting or cooling fluids.

As for material efficiency, improvement potentials can be found in avoiding waste materials or quality rejects as well as fostering recycling concepts. In the planning phase, digital methods can support to derive material efficient designs. While for operation, digital methods can help to derive root causes of material inefficiencies and low quality rates.

Call to action

As indicated, there are manifold digital solutions that can potentially support to significantly improve the environmental impact of manufacturing. Driven by various actors, manufacturing processes must minimise negative environmental impacts. Balancing energy efficiency, material efficiency and substitution is challenging; possible approached include visualisation, transparency on root causes, prediction and ultimately autonomous adaption. A digital environment will allow companies to develop a scalable decision-making support tool to identify and continuously improve measures for a target oriented energy and resource management. It opens up new manufacturing possibilities in monitoring and improving their energy and resource demands by creating recommended scenarios that indicate how to improve efficiency, transparency, utilisation of energy and resources, and, at the same time, is compatible with the current digital infrastructure of the company.

If you wish to know more about how Energy and Resource Management can be useful for your manufacturing setup? Please contact Fraunhofer Project Center at the University of Twente and we will explore this together.

Figure 3: Reference framework for digital solutions towards sustainable manufacturing [5]