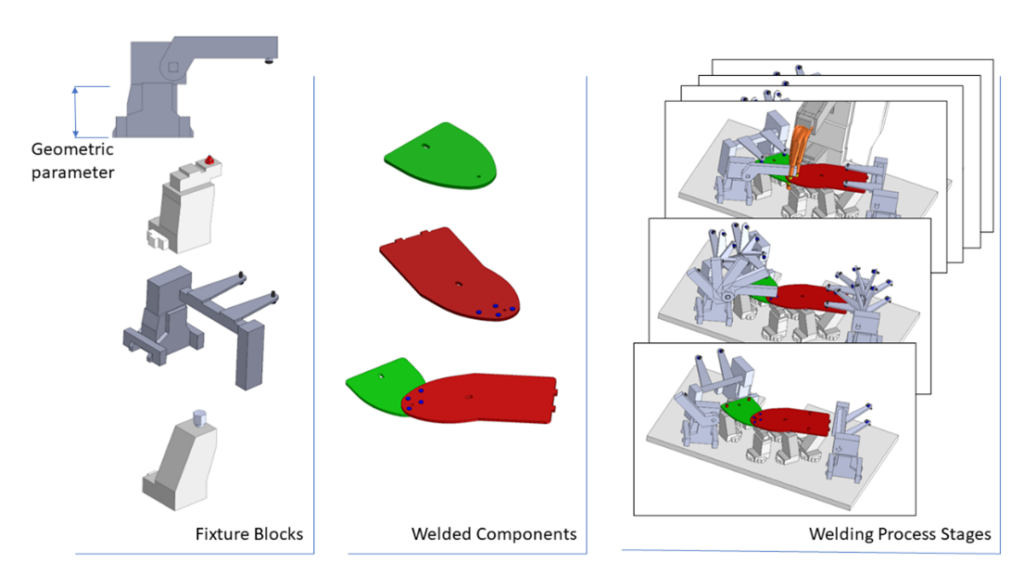

Welding fixtures are applied to clamp, support, and locate the components to be welded, in order to meet product tolerances by minimising deformations due to welding. The design of welding fixtures is one of the many engineering domains requiring a continuous reduction in their lead-time processes to keep up with the industry’s demand. A large proportion of the lead time results from repetitive tasks and analyses performed for each new design. In an attempt to reduce the designer’s efforts during the execution of these tasks, an automation solution can be realised.

The Fraunhofer Innovation Platform for Advanced Manufacturing at the University of Twente, in collaboration with MechDes Engineering B.V., have worked towards a design automation prototype capable of producing feasible design concepts. The welding fixture design concepts generated were based on the designer’s criteria and product standards.