Case study

Automated fibre array system

PHIX worked with the Fraunhofer Project Center at the University of Twente (FPC@UT) to develop a precision assembly cell to produce fibre array units (FAUs) with polarisationmaintaining fibre (PMF). Currently, these fibres are produced using a manual labour process which constitutes 50-80% of the total production cost. To significantly reduce the cost, the project team focused on automating the process. Using a prototypical machine provided by AIXEMTEC – an Aachen-based spin-off of Fraunhofer IPT who cooperated in the project – the firms together initiated a two-part feasibility study and development project. The result was a machine that autonomously builds consistent products in minutes rather than hours.

Feasibility Study

The first part of the feasibility study involved designing a prototypical process for assembling the fibre arrays. This was successful, in that it produced small quantities of FAUs with the achine in a semi-automatic mode, though still requiring some amount of operator intervention. Spurred on by this early progress, the team decided to further pursue the concept with the goal of fully automating the assembly process.

The second part of the feasibility study analysed possible tool chains for automating fibre preparation to provide input material for the machine. The partners needed to establish an in-depth understanding of the prototypical FAU assembly machine from the first part of the study (hereafter referred to as the FAAST machine), along with the input material requirements and the boundary conditions of the fibre array assembly process. The focus was on repeatability of the fibre input material as well as the pickup and transportation of fibres between the various fibre preparation and inspection stations and eventually to the FAAST machine itself. This development work complemented the functioning assembly process from the first part of the feasibility study and established a standard working procedure for both the operator and the process engineer.

System Overview

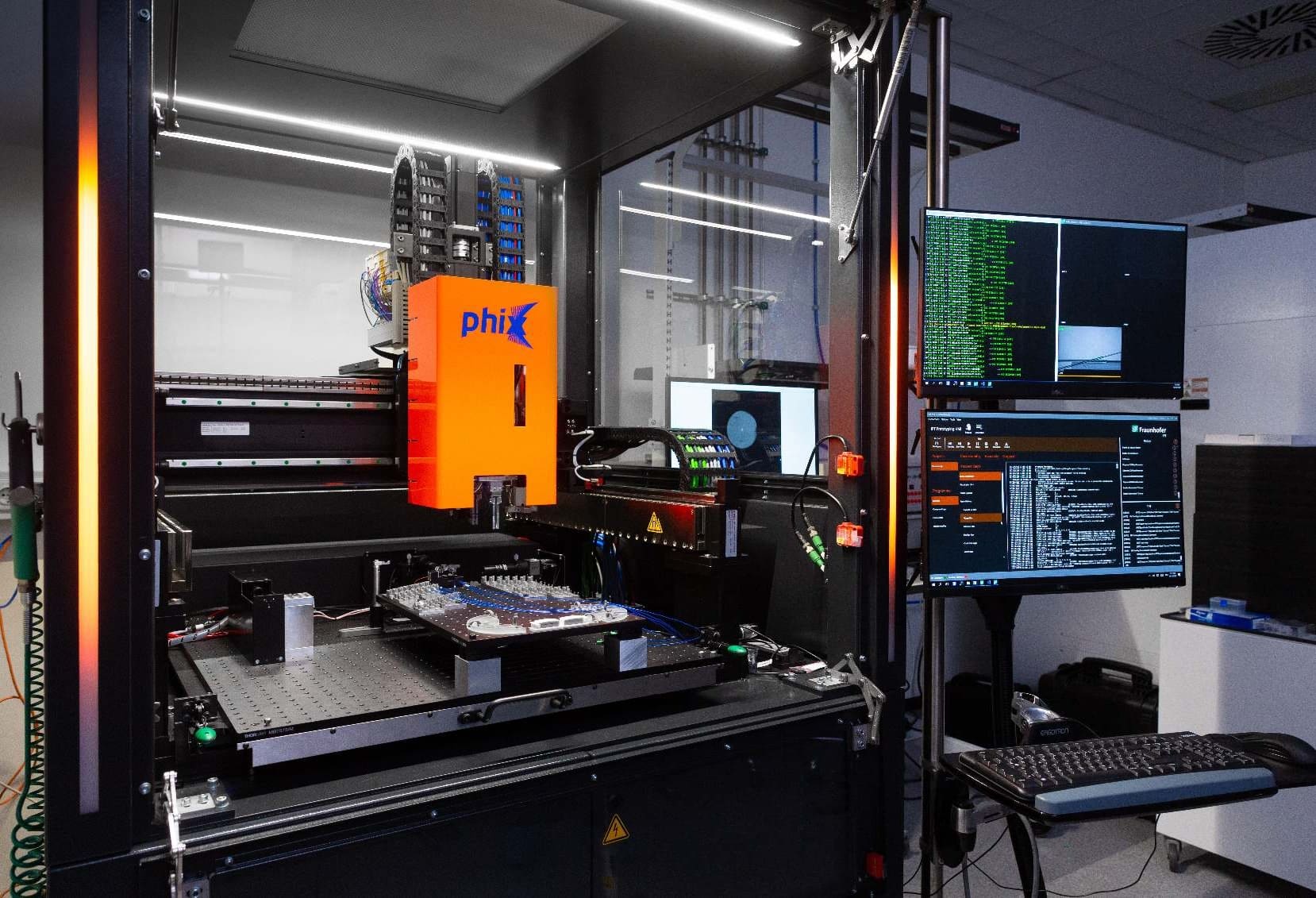

The FAAST machine consists of three major systems:

- a 3-axis gantry unit consisting of an X-Y long-travel precision linear robot using a magnetic drive and a vertical Z linear motor spindle drive,

- a modular tool head, mounted on the Z-drive of the gantry system and equipped with a fixed pneumatic gripper, a piezo-based fibre rotator, UV illumination, a topdown camera and an adhesive dispenser, and

- an optical breadboard with various stations where the actual FAU assembly takes place.

The functional stations of the breadboard include a fibre garage from which the fibres are picked, a tool calibration unit for referencing the global coordinate system, a needle cleaning unit, a referencing station for setting fibre pitch angle, and finally the assembly station with front and side cameras where the parts of the assembly come together to form the finished FAU.

Assembling a fibre array, at its most fundamental level, involves bringing together a base chip with precision-sawn V-grooves, the individual fibres themselves, and a lid chip that holds everything together. In comparable manual processes, the stress rods of all fibres are aligned simultaneously by rotating the fibres on their axes, and only after all fibres have been aligned is the adhesive cured. Because of this, neighbouring fibres can physically interact during the alignment process and influence the accuracy of one another. To complicate things further, this undesirable interaction increases as the fibre count in an array increase.

During assembly with the FAAST machine, the fibres are attached to the base chip one-by-one with micrometre precision and fixed in place with a UV cured tacking adhesive. This strategy simplifies and makes scalable the process of aligning the stress rods that serve to maintain the polarization in the fibres. Only after all fibres are in position is the lid placed and underfilled with adhesive to make the final, permanent bond.

Challenges

To place the fibres in the V-groove reliably while not clashing with previously tacked fibres, the fibres need to be oriented at a slight angle in the pitch rotational axis. As part of the development with FPC@UT, a new fibre referencing station was introduced to the breadboard. As measured by a new process routine developed by Fraunhofer IPT using the side camera, both the accuracy and the repeatability of the fibre angle were greatly improved. Another challenge that was encountered related to the dimensional tolerance of the fibre acrylate coatings. This resulted in unreliable tacking of the fibres. Because the tolerances come from the manufacturer and could not be influenced by the project partners, a new placement strategy had to be developed to compensate for the variations. An initial version of this strategy exhibited a new mechanism of yield degradation, but a revision of the process resolved this issue. The final strategy was demonstrated to work reliably with 8-fibre arrays and is compatible with larger fibre counts.

Conclusion

Automating the assembly of a fibre array is a non-trivial challenge, especially when considering polarisation-maintaining fibres (PMF). When performed manually, a highly skilled operator and considerable time is needed to achieve an acceptable result. There are many processes that need to be designed, tested, and optimised to automate the process. Based on initial feasibility studies and iterative improvement, a stable automated process has been delivered to PHIX. Challenges such as accurate fibre pitch angle requirements as well as manufacturer tolerances of input material have been overcome. Moreover, general process optimisations cut the overall cycle time for a fibre array assembly in half without sacrificing yield.