MIND YOUR OWN (SUSTAINABLE) BUSINESS

a manufacturing approach

Sustainability. We hear that word everywhere nowadays. But, what does it mean? And what can industry do about it? The term sustainability is generally defined as the balance between social, economic, and environmental aspects. Every product in our built environment is manufactured somewhere, using many human, energy and material resources, and producing a certain amount of waste, only to (partially) end up in a landfill once it reaches the end of its functional life.

For industry, more and more companies are realizing that there are substantial economic and social benefits resulting from adopting sustainability. Resource efficiency, workforce satisfaction, reduction in fossil fuel dependency, and use of new technologies are just a few examples of sustainability-related activities that will help the industry thrive for years to come. From a business perspective, sustainability offers economic benefits that can be leveraged through the balance of the social and environmental areas. But, reaching that balance is proving to be the most challenging aspect of sustainability.

For the manufacturing industry, there are a couple of important questions to answer:

Sustainable manufacturing? Or manufacturing sustainably?

Making industry more sustainable means making the manufacturing process more environmentally friendly (sustainable manufacturing), and in a manner that can still bring longterm social and economic benefits (manufacturing sustainably).

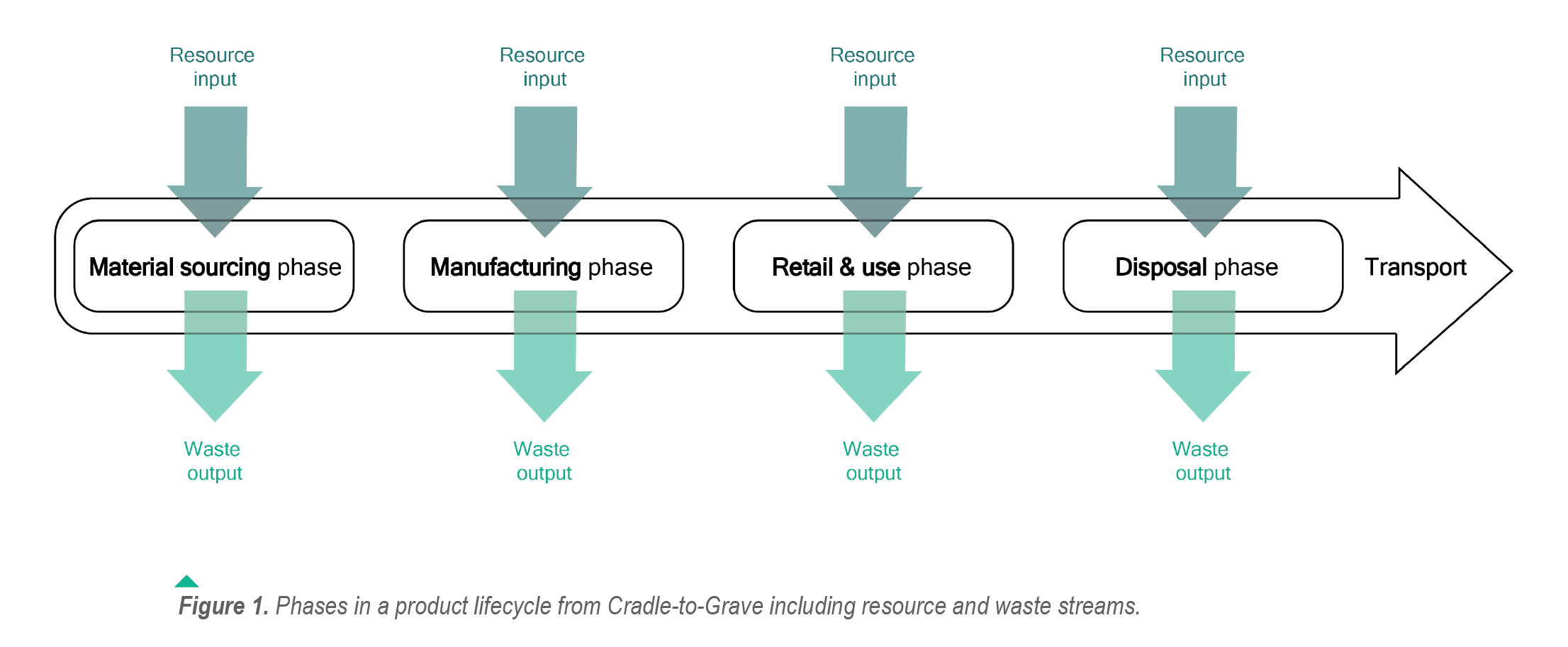

A product, service, or process usually follows a linear lifecycle, also referred to as cradle-to-grave, that consists of four

main phases:

1) Material Sourcing (cradle),

2) Manufacturing,

3) Retail and Use, and

4) Disposal (grave)

When talking about sustainable manufacturing, we talk about measuring the impact of a product throughout all the phases of a product lifecycle. As can be seen in Figure 1, the transport required for bringing the (un)finished product to its destination for the next phase, and the resource input and waste output, are also important parts of the product lifecycle to consider. Everyone who takes part in manufacturing, regardless of company size or their role in the product lifecycle, can play a part in reducing the negative impact of their operations. This is what we call sustainable manufacturing. When talking about manufacturing sustainably, we refer to the ability to keep a business operational. This is done by providing a positive impact to society and the environment, without compromising the industry’s ability to grow or create value.

Manufacturing sustainably may mean offering properly remunerated jobs, a healthy and safe work environment, manufacturing products with large societal value, reducing resource and waste streams, aiming for circular processes, or offsetting carbon outputs through alternate environmental activities such as reforestation. So, should we strive for sustainable manufacturing or to manufacture sustainably? For the manufacturing industry, the answer is both.

Measuring sustainability

Measuring the footprint of an organization, whether it is from an environmental, social, or economic perspective, is the critical step for keeping a business relevant in a market that is constantly subjected to the effects of climate change. Most of the time, organizational strategic decision making processes are economically driven. Not necessarily because organizations are not concerned about their societal or environmental impact, but because the impact is difficult to quantify and translate into indicators that may provide valuable business insights. Lack of knowledge around climate change, lack of awareness around corporate sustainability developments, and lack of accurate impact assessment methods are contributing to a delay in corporate climate action. But no company should go through change alone. Recognizing the need for action is already a good first step on the road toward sustainability. The second step should be translating impact into social and environmental indicators that kickstart corporate action.

Kickstarting sustainability

You work in industry and you want your company to become more sustainable, but where to start? A Sustainability Officer (SO) can help carry out a holistic analysis of the organizational status, as well as fill in the knowledge gaps necessary for further action.

A SO should be able to help your organization answer the following questions:

The answers to these questions will vary on a case-by-case basis but will help shape the appropriate next steps for your organization. In most cases, the results will depend on the organization’s strategic priorities, market position, growth opportunities, and changereadiness level. Most companies will want to measure the ecological footprint1, or ecological impact of a certain product, service, or process. One way to measure impact is through an LCA (Life Cycle Assessment), which offers a standardized approach to understanding the impact associated with products, services, or processes.

Why you need an LCA

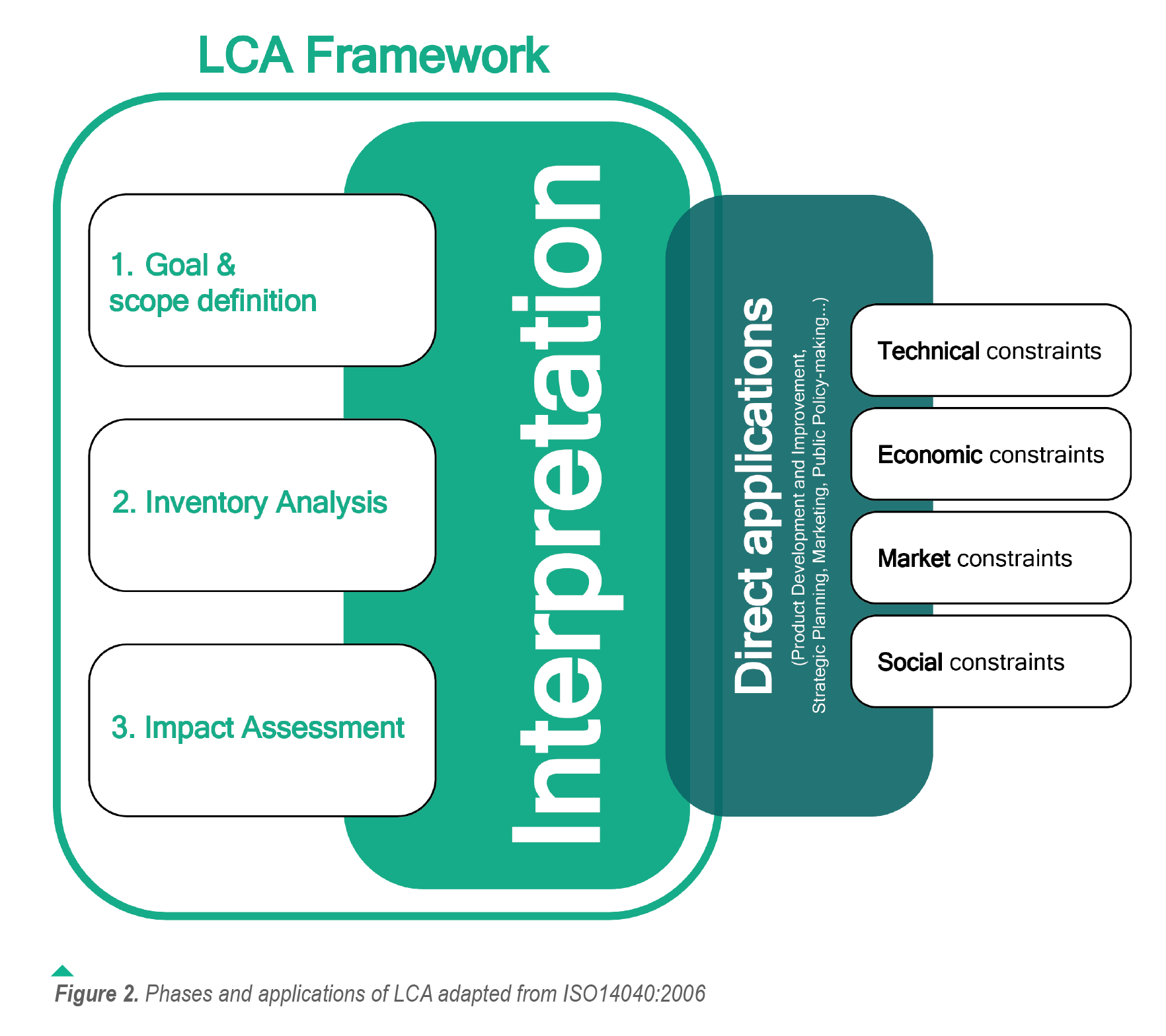

Measuring the ecological footprint is not an easy feat. The LCA framework as defined in ISO 14040:2006, is a methodological approach consisting of four phases as shown in Figure 2.

1. Goal and scope definition:

The first step is always to define what the goal of the study is, and the assessment boundary conditions. In a layman’s terms;,the extent of lifecycle phases and processes to be included or excluded from the study.

2. Inventory Analysis (LCI):

The second step is to create a detailed list of all the resource and waste streams related to each of the phases and processes. This will help identify the amount of resources allocated to creating a product and its environmental

contribution related to the organization in question.

3. Impact Assessment(LCIA):

This part involves categorizing the identified impacts, quantifying the relationships, and assigning relative values to be compared with benchmarking values. This can all be translated into a single-score indicator.

4. Interpretation:

Finally, the most critical aspect of an LCA is what to make of all the resulting information. An SO is important to have to provide a valuable and objective perspective on how to convert the results into corporate actions.

This is arguably the most important step of all, considering that the organization may be able to use this information to disclose its role and impact on the planet.

(1)Ecological footprint:

An analysis that compares human demand with the planet’s capacity to regenerate. In most cases, especially in manufacturing, the footprint is represented by the amount of biologically productive land and sea needed to regenerate the resources consumed and absorb the corresponding waste generated by the production process

Altogether, an LCA can bring the manufacturing industry multiple benefits. It can help by:

- Environmental Impact Evaluation: Identifying improvement opportunities for the environmental performance of a product

- Regulatory compliance: Informing stakeholders such as industry, governmental, and non-governmental organizations

- Sustainable design: Encouraging the use of eco-design principles by providing insights into environmental hotspots

- Resource efficiency: Highlighting resource and energetic consumption patterns to optimize use and save costs

- Waste reduction: understanding the environmental impact of waste generation and promote recycling or material reuse

- Decision Making: Selecting relevant indicators for environmental performance that can be translated into corporate action

- Marketing and consumer perception*: communicating environmental performance can boost consumer confidence and attract environmentally conscious consumers.

*It is important to highlight that any product in the market with environmental claims, ecolabels, or social impact statements, should have gone through an LCA process that includes a critical review from an external party or SO. This is done to limit greenwashing schemes, enable consumers to make informed decisions, and support science-based claims. However, it does not mean that all product labels or claims have indeed gone through a standardized and critically reviewed LCA process.

A green takeaway

Regardless of your motivation for sustainability, it is clear that the world is moving in a greener direction. The train of sustainability is full of opportunities for manufacturers of all kinds, it brings all kinds of short and long term benefits. Whether it is a happier and more productive workforce, a smaller (negative) environmental impact, or resource efficiency and cost reduction, the journey towards a greener future starts with you.