EMPOWERING PRODUCTION

How Gemineers Realizes The Digital Twin in Metal Cutting

As the first morning light pierces through the windows of a manufacturing company somewhere in Europe, a machinist steps into a bustling workshop. He grabs a cup of coffee from the vending machine, hoping to chase away the last bits of morning fatigue. With a flutter of excitement in his heart, he approaches his CNC machine. Flicking the switch, electrical drives hum to life, cold light illuminates the machine room, and an endless stream of numbers rushes over the control panel.

He retrieves his tablet PC and routinely presses on a symbol showing two colorful semicircles. His web browser opens, and a dynamic animation materializes into a captivating symbol of a digital twin. Logging in, he instantly accesses a detailed overview of the products machined in the night shift, feeling a sense of contentment with the productive outcome. A lined-up set of bright and greenish digital twins is floating on the dashboard, one for every fi nished workpiece sitting in the pallet storage right next to him, indicating that chips were fl ying smoothly while he was still in his dreams.

This is how the startup gemineers envisions just a small part of everyday life in a digitized manufacturing environment. And this is how they have already been able to demonstrate it to numerous companies in the machining industry.

Founded in 2021 and emerging as a deep-tech startup from Fraunhofer Institute for Production Technology IPT, gemineers off ers an innovative and application-oriented digital twin solution to customers, with a strong focus on machining technologies. gemineers’ digital twin platform revolutionizes the way metal cutting processes are optimized and managed. By combining real time data, technology know-how and advanced analytics the platform enables manufacturers to create precise virtual replicas of their manufactured products. These digital twins provide valuable insights into machining operations, optimizing effi ciency, reducing waste, and improving overall productivity. In addition to technological and economical characteristics, the platform can also be used to precisely quantify and optimize ecological indicators such as resource consumption or CO2 footprints in production.

Following a start-up funding from the Fraunhofer-Gesellschaft in 2019, subsequent research transfer funding from the German government in 2021, and its recent seed investment round in 2023, gemineers is now an advancing company with customers in various industries such as mold and die, aerospace, and semi-conductor. Since the beginning of 2023, the Aachen based startup also supplies its platform upon customer request to two of the largest european machine tool manufacturers, DMG MORI AG and Grob-Werke GmbH & Co. KG.

The gemineers team consists of passionate experts in manufacturing technology and software development. From their own experience in the planning and implementation of machining processes, the team’s strong desire from the beginning was to provide machinists with an application-oriented everyday working tool. Accordingly, the gemineers digital twin platform is tailormade to support process monitoring and optimization tasks in machining, as they occur for example in the prototyping or ramp-up phase of new products. Apart from that, the ability of the platform to create a precise digital twin of a machined product predestines it for the application as a data-based quality assurance solution, providing 100% quality control and documentation immediately on the shopfloor. Thereby, conventional tactile or optical measurement efforts can be reduced to a minimum.

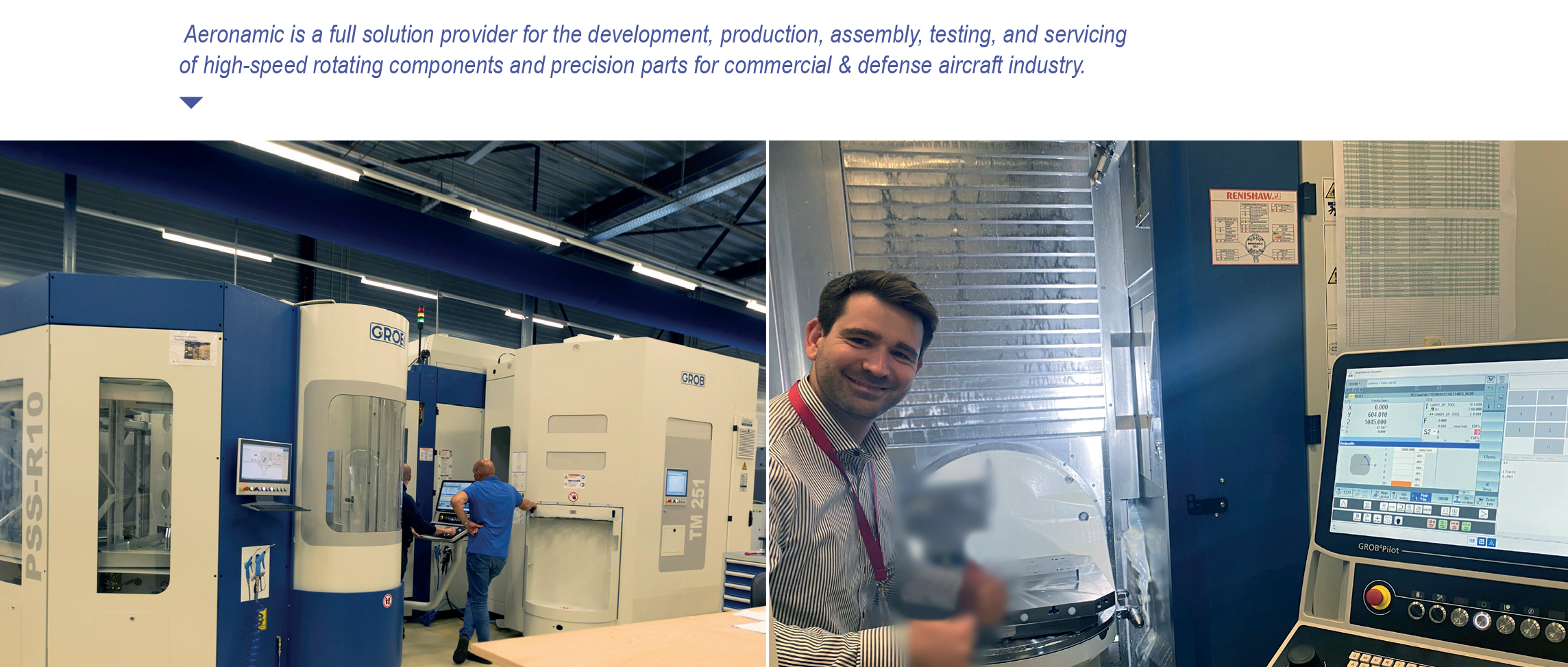

It was probably not only the technological innovation potential of the gemineers digital twin platform that moved Ronny Blaauwgeers of the Dutch company Aeronamic to test the system in his own production. With its capability of precisely calculating important productivity and quality indicators, even across series production, the platform possesses a high level of attractiveness not only for machine operators but also for production engineers and management.

Accordingly, Ronny is pleased that theoretically, an insight into Aeronamic’s machining processes, from annual production output down to a single cut, is always just a browser click away, for him and for everyone else in the team. However, Aeronamic is recently facing a large customer order for a very complex and demanding component from the aerospace sector and is therefore currently putting the gemineers digital twin platform through its paces from a technological perspective first.

“At the moment, we are testing the gemineers digital twin platform with regards to process monitoring and optimization in the ramp-up phase of a complex aerospace part.” says Ronny Blaauwgeers. “We firmly believe that solutions such as the gemineers platform are the future of metal cutting. While our company is still in the testing phase to understand its capabilities, I am confident that the outcome will be positive. This platform has the potential to revolutionize our metal cutting operations, optimizing processes and driving efficiency.

The fact that the gemineers software solution runs on multiple machine brands and multiple machine controllers, makes this an attractive solution. We successfully tested it on a Grob G550T with Siemens and on a Hermle C22 with Heidenhain controller. Meanwhile the data is kept on-premises within Aeronamic. We made parts of the data accessible for support by gemineers in a controlled way, so we do have data security and at the same time maximize the potential of the gemineers software.”

In the coming weeks, gemineers will continue to closely support the Aeronamic team in further testing of the platform in production. As always, production testing is also a valuable source of feedback for gemineers to further improve and exactly meet the customer’s expectations in terms of functionality and return on invest. The entire project team is confi dent that

everything continues to run smoothly, and that the assessment can be finalized in the second half of the year, eventually

aiming for a production roll out of the system.

For more information please contact:

info@gemineers.com

Tel.: +49 241 4095000

Bendstraße 50/52, 52066 Aachen, Germany