Message from the editor

By highlighting the transformative impact of connectivity on reshaping manufacturing and emphasizing the collaborative synergy between academia and industry, how will the Advanced Manufacturing Centre, as an innovation catalyst and knowledge hub, drive manufacturing towards a more connected and prosperous future?

Featured

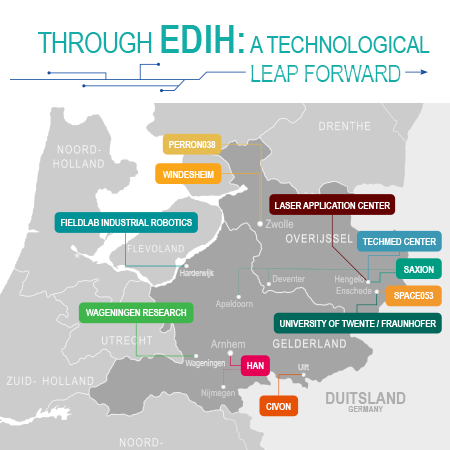

Boosting Robotics Innovation in East NL

In the East Netherlands, a network of knowledge institutes drives robotics innovation, offering tailored digital transformation solutions to SMEs and positioning the region as a tech-forward hub shaping Europe’s innovation landscape.

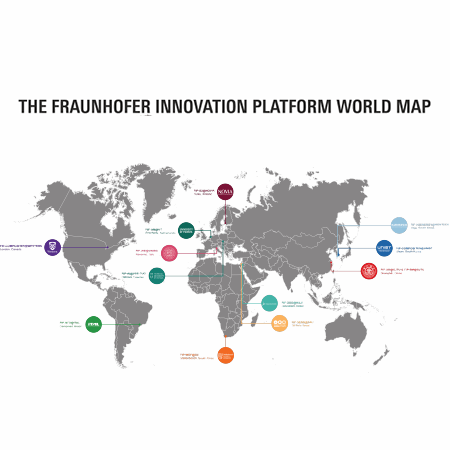

Fraunhofer Innovation Platform purpose to industry

The Fraunhofer Innovation Platform (FIP) fosters collaboration between German Fraunhofer Institutes and global partners, merging research and practical application to enhance products, cut costs, and drive innovation across industries. FIPs offer market analysis, consulting, and expertise networks, promoting pre-competitive cooperation and innovation in various sectors.

Lessons Learned

Why connectivity is vital to high-tech manufacturers

In high-tech manufacturing, connectivity is essential for data-driven decisions, Industry 4.0 adoption, supply chain optimisation, and seamless communication. Modern networks like SD-WAN and 5G are crucial for supporting digital transformation. The Fraunhofer Innovation Platform at the University of Twente assists manufacturers in achieving their factory goals.

Is there value for SEA and SEO for manufacturers

Manufacturers can leverage the benefits of both SEO (Search Engine Optimisation) and SEA (Search Engine Advertising) to increase online visibility, reduce marketing.

Raising awareness on diversity and inclusion

DIVE, a collaborative project with software and manufacturing firms in Twente, aims to raise awareness about diversity and inclusion through a board game. It helps companies assess their diversity and inclusion approaches and offers insights for improvement.

Sustainability

Mind your own (sustainable) business

Sustainability is becoming increasingly important in manufacturing. Balancing social, economic, and environmental aspects is crucial. It offers resource efficiency, worker satisfaction, and reduced fossil fuel reliance. Both sustainable manufacturing and manufacturing sustainably are key. How can you measure your impact and drive meaningful actions with tools like Life Cycle Assessment (LCA)?

AMC NU

AMC NU

Get a sneak peek of our Advanced Manufacturing Centre & discover the many innovation topics we can use our Advanced Manufacturing Program subsidy for to support your business.

Technology & Innovation

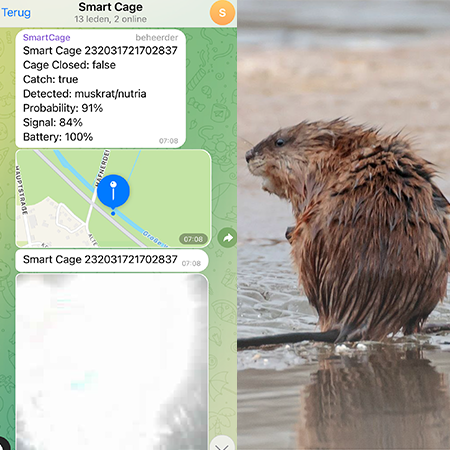

Innovation & Technology for nature management

Robor Electronics began with a horse birth alarm in 1995, evolving into IoT devices. They integrated GPS tracers and birth alarms into trap detectors for efficient muskrat control. In collaboration with the Life MICA project, they developed Smart Life Traps using AI and cameras to target specific animals, reducing bycatch. Challenges persist, but this highlights technology’s role in conservation.

Is MES the ‘Silver Bullet’ to become a truly data-driven manufacturing business

Manufacturers must go data-driven for efficiency and sustainability. Manufacturing Execution Systems (MES) collect, standardise, and optimise data, improving quality and innovation. Success needs organisation-wide support and data governance. An MES is a vital step in achieving data-driven manufacturing.

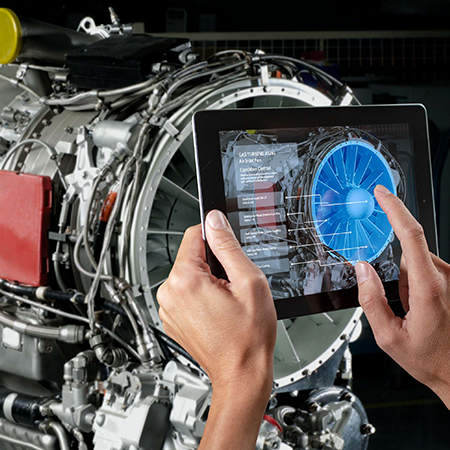

Transforming aerospace manufacturing

The Omnifactory® is an advanced aerospace manufacturing testbed enabling agile and cost-effective production. It integrates digital and physical elements, offering scalability and flexibility for efficient, sustainable manufacturing, supporting the transition to a circular economy.

Connectivity in laboratories and on the production floor

The manufacturing industry is embracing digital transformation with cloud-connected instruments for remote monitoring and enhanced data analysis. Malvern Panalytical’s Smart Manager enables proactive maintenance and unlocks valuable manufacturing data. Challenges include security and reliability. Contact them to explore this transformative journey further.

Small steps lead to giant leaps

Manufacturing adapts to global challenges with ICT-enabled tools and 5G connectivity. They improve efficiency and agility, with 5G private networks offering secure data handling. Manufacturers should choose relevant use cases like autonomous robots and augmented reality, based on digitisation levels and stakeholder input, for future success.

The CO2 footprint

Manufacturers must address sustainability demands by tracking ecological footprints. European legislation like ESG requires comprehensive data on CO2 emissions and production throughout the supply chain, with compliance facing challenges in data uniformity. The European Digital Product Passport, backed by the NXTGEN HIGHTECH Growth Fund, seeks to automate data exchange using existing ERP systems and SCSN infrastructure, offering solutions for manufacturers through ECI.

The paradigm shifts in manufacturing

The Fraunhofer International Center for Networked, Adaptive Production (ICNAP) is tackling manufacturing challenges with five studies in 2022. They cover pricing models for industrial data, real-time digital twins, sustainable production, cybersecurity, and data-driven production using industrial data spaces. These studies emphasize innovative solutions for the manufacturing sector.

Empowering production: How gemineers realised the digital twin in metal cutting

Gemineers, a Fraunhofer Institute startup, offers a digital twin platform for machining. It optimises metal cutting processes with real-time data and analytics. With machine tool manufacturers and diverse industry customers, it aids process monitoring and quality assurance.