New impulse for the micro-assembly theme

The large number of spin-off companies operating in the Twente region was one of the main reasons for setting up the Fraunhofer Project Center (FPC). Now that a number of these companies are aiming to scale up their production considerably, it is important that they can make full use of the knowledge and expertise of the partnerships within the FPC in the fields of production technology, digitalisation and precision assembly. Since spring 2021, the coordination of this last area of expertise lies with the NanoPhysics research group of Saxion University of Applied Sciences.

This research group has been partnering with the FPC for several years, but with this increased involvement it can now really accelerate the precision assembly research line within the center. Twente is an interesting region in that respect. There are many microand nanotechnology companies here that started product development a few years ago. Now they enter the next phase: scaling up production and the subsequent market introduction of their products.

In this next phase, the NanoPhysics research group, responsible for the Precision Assembly domain at FPC, is an important driver that can bring all relevant parties together. This research group has a large network of companies who can benefit from the new technologies, but also have access to the knowledge and lab facilities of the Fraunhofer Project Center for the further development of those companies. This is also the role of the FPC: to develop new technologies together with universities and other research collaborators to make them available to industry.

What is Precision Assembly?

Precision Assembly involves placing and connecting components with an accuracy of several micrometers, sometimes even less. Examples are microfluidic chips where exact amounts of gases or liquids must be delivered at exactly the right place. If the alignment of the components is not good, the system does not function. Also for integrated photonics, where light must be introduced into the waveguides of a chip at the right position, it is all about the very precise alignment and connection of various components necessary to control or read the chip. It is one of the processes that researchers from Saxion and the FPC are investigating together with companies in the region. Now a lot of assembly work is still carried out manually. The question is how this can be further automated, while maintaining – or preferably improving – the quality, making it possible to produce products with those chips faster and in larger quantities.

The demand for these types of products is already high, but is expected to increase considerably. For example, Point of Care devices, such as rapid testing to detect diseases (at an early stage) via a drop of blood or urine, can make a very relevant contribution to healthcare. Once they become available on the market, it will drive the demand for very large quantities of test chips, each of which will probably have to be assembled in cartridges.

The Precison Assembly programme line

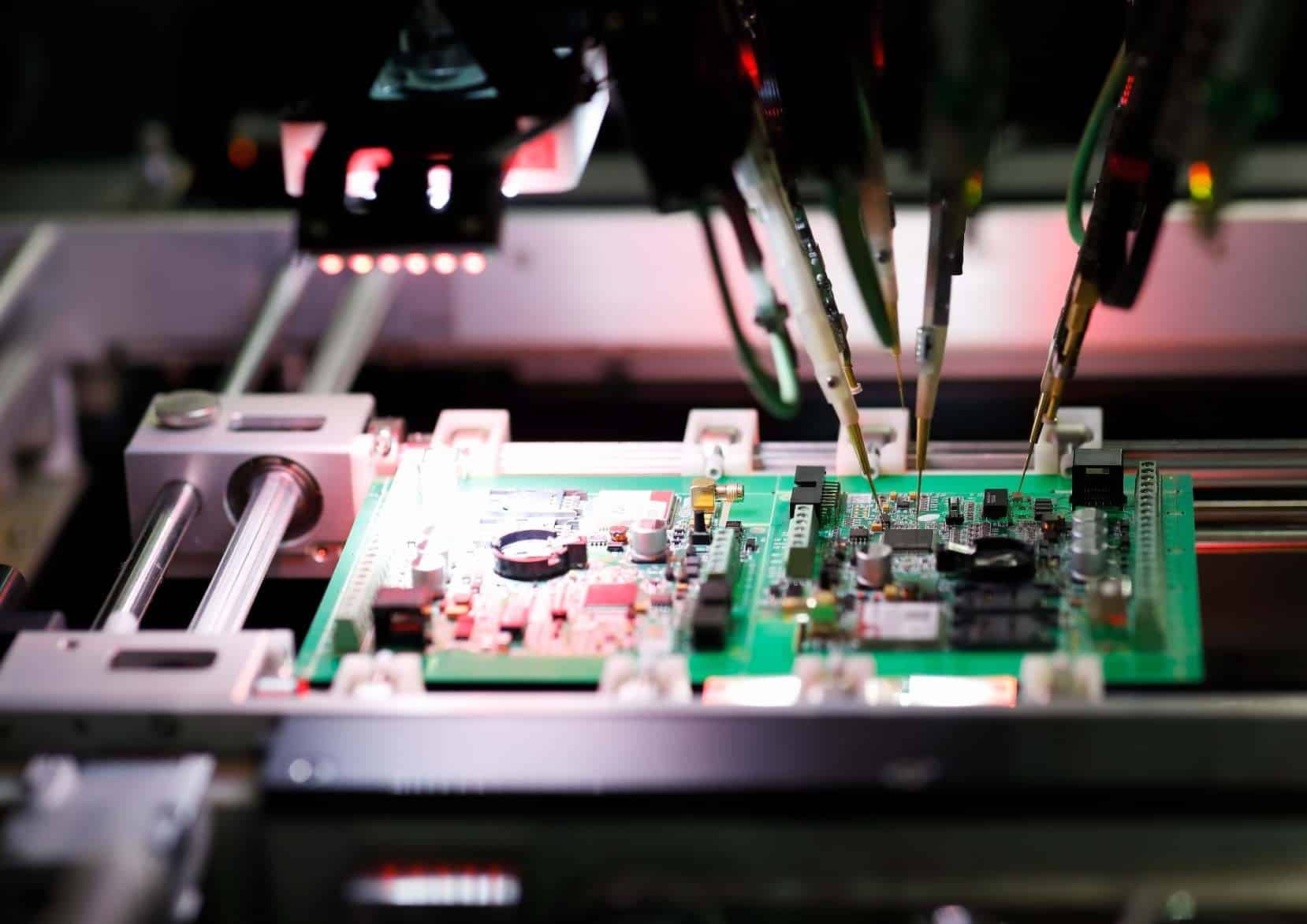

With the lab facilities available at the FPC, researchers and students, under the direction of the Saxion research group, develop and test processes on a micro-assembly machine developed in Aachen, Germany. These processes are an important intermediate step in upscaling towards volume manufacturing: it is not yet about making millions of products, but about mapping out the right processes. The researchers will provide the knowledge gained from these studies to the companies. This allows them to actually shape the upscaling. The Precision Assembly programme line, which is now being steered from Saxion, is one of the technical domains that were set up in the collaboration between the Fraunhofer-IPT, the University of Twente and Saxion. Within this domain, the NanoPhysics group can use its substantive added value and network to boost research and associated applications with chip technology. In addition, the team has access to a wide network of research groups from both the University of Twente and Saxion, which can be engaged if specific knowledge is needed.

A double edge knife

An important reason for Saxion to be actively involved in this programme is the possibility to link various bachelor and master students to the research. The knife cuts both ways: the students are introduced to state-of-the-art machines and processes and at the same time, the results of their work are directly relevant to the companies involved. For example, in the past semester, three graduates worked with the machine in the lab at the High-Tech Factory located at the University of Twente campus. These students have developed a process to align a waveguide on a photonic chip with high accuracy in front of an optical fiber to have optimum light coupling. The required accuracy to establish this coupling is on the order of 1 micrometer. The special thing is that machine vision is used, finding the correct position based on an image taken with a digital imaging microscope within the system.

The future

The goal for the coming years is to build up enough expertise and knowledge to take a key position in the middle of the group of companies that are fully scaling up their production. Students and researchers, both from Saxion and the University of Twente, carry out the various studies, but always in close cooperation with the FPC, Fraunhofer IPT and the companies involved. Saxion can play the role as a stepping stone for companies towards the Fraunhofer Project Centre. In this way, everyone benefits. The institute has a machine that students have access to and love to work with. By working with the machine, they gain relevant knowledge. At the same time, the research team forms a link between all parties. To meet the growing societal demand for products based on chips, there is now a serious opportunity to take great steps forward.