Kick-staring AI in production

Application areas, publicity available data sets and successful implementations

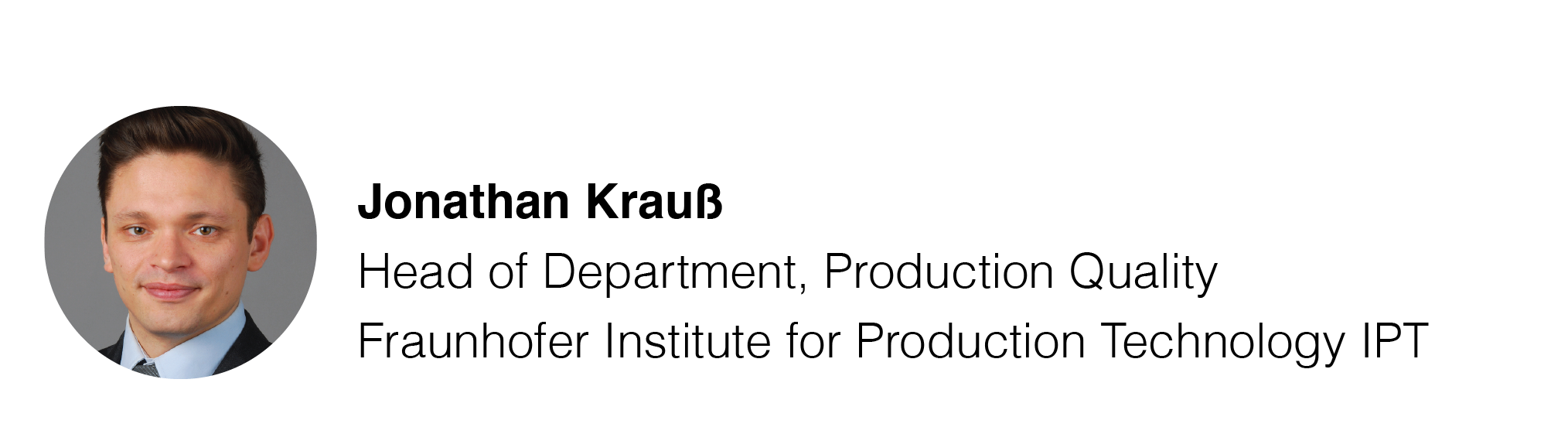

Figure 1: Overview of the application areas Process, Machines & Assets and Product. Below, application areas are located in production and circumscribed with applications. [3–5, 7–11, 13]

Increasing computing power and better data bases with simultaneously decreasing costs for computing and storage capacities represent the basis for the use of Machine Learning (ML) in production. As a result, ML methods are increasingly being used in production. ML methods can be used to train artificial intelligence (AI) systems, which the majority of companies hope will increase their productivity [1]. Challenges on the path to AI systems in in-house production include identifying promising application areas, recognising the associated learning tasks, and uncovering suitable data sets.

Application areas for AI and ML in production

The decision to apply ML in production is made for a wide variety of reasons and by different people in charge. In some cases, it is the process owner who wants to solve a specific problem. In others, it is the management level that wants to test the use of ML. In each case, the basis is the choice of the right application area in the company. Existing studies, which give an overview of possible application areas, often only consider partial aspects of modern production facilities. A high level of abstraction or a lack of topicality mean that these studies are only suitable to a limited extent for identifying the company’s own problems. [2–13]

In order to provide a basis for the selection of a use case, the Fraunhofer IPT identified the application areas shown in Figure 1. These are based on our own studies as well as experience from industry and research projects. The use cases can be divided into three clusters: Process, Machines & Assets, and Product. Through the overview, new projects can be identified and starting points for data collection in production can be found.

In order to prioritise projects, it is necessary to assess whether the corresponding data basis is sufficient. This is possible if the project team is interdisciplinary and the employees have built up expertise in the field of data science. In addition to theoretical knowledge, the employees involved should have gained experience in the use of ML with concrete data sets.

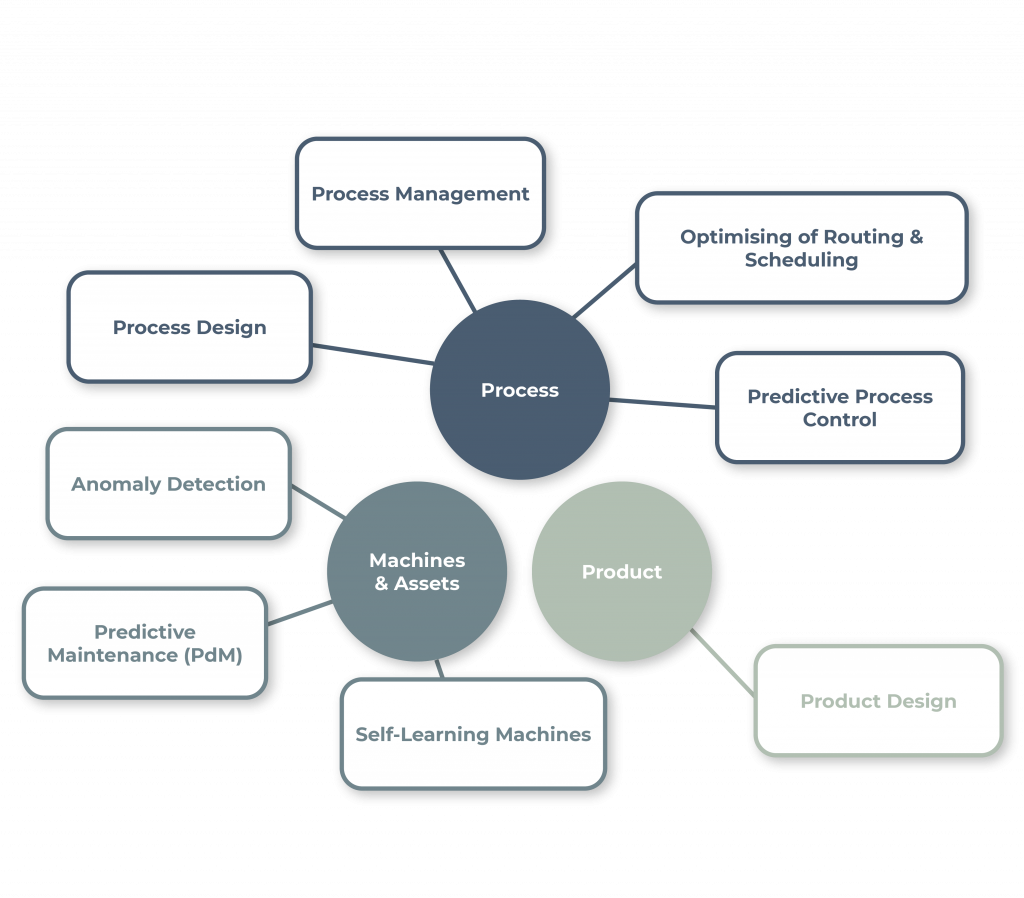

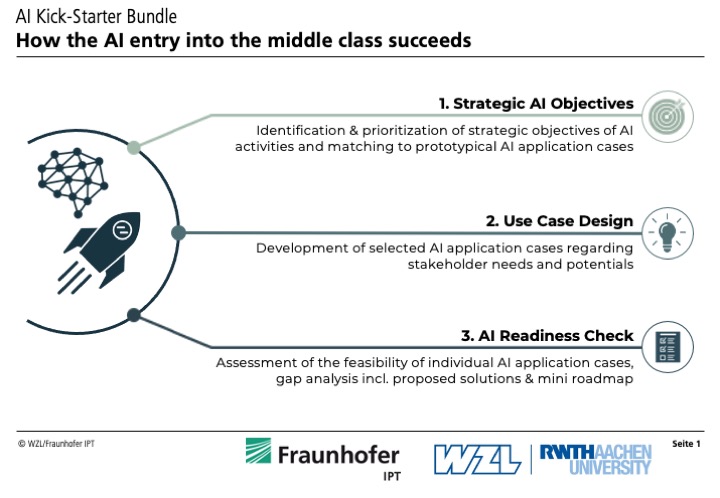

Figure 2: AI Kick-Starter Bundle of Fraunhofer

Data basis in production

The lack of experience of employees in dealing with AI and ML leads to the fact that the overwhelming number of ML projects fail despite increasing data volumes [14, 15]. One of the reasons for the lack of experience is that the company’s internal data is unstructured, does not contain the relevant information or is not stored in sufficient quantity [16]. In these cases, it is possible to gain initial experience in the use of ML using freely available data sets. However, the data sets that are publicly available in the area of production are stored on different platforms.

For these reasons, publicly available data sets were elicited at the Fraunhofer IPT to gather initial experience with the focus on “production”. These available data sets can be assigned to the application areas named above. The entire overview can be accessed via the link ipt.fraunhofer.de/ml-and-ai-in-production.

Apply AI and ML successfully

Once the application area has been defined and the necessary experience is available, a future challenge for companies will be to certify the processes and products in which the AI systems are used. The limited determinism of ML models will lead to a rethinking of the corresponding entities and will be actively shaped by the Fraunhofer IPT and the Fraunhofer Big Data AI Alliance [17–23].

In summary, the two biggest obstacles for companies at present are identifying the most promising AI use cases and realistically assessing the corresponding data basis. As described in the article, the corporate strategy should be to build up in-house expertise. In addition, it is a good idea to take the first steps on the way to an AI project together with external partners. The “AI Kick-Starter” service developed within the Fraunhofer society (see Figure 2) is an opportunity for companies to evaluate and prioritise their use cases in a targeted manner [24].