Fuelling the Future

How the Advanced Manufacturing Center will drive the rapid transformation of industry across The Netherlands

The need for sustainability and resiliency in manufacturing has never been clearer as massive disruption continues to sweep across the sector. Driven by global economic uncertainty, huge fluctuations in demand, and a rising tide of technological innovation, manufacturing is joining the fourth industrial revolution, and it’s poised to change our lives. But achieving growth in a time of rapid and unpredictable change presents a huge challenge, and one that’s notoriously difficult for businesses to plan for.

The Advanced Manufacturing Center will help businesses overcome that universal challenge and drive innovation across the industry in the Netherlands and beyond. Set to open its doors in 2022, the open innovation center will combine people, technology, and process to develop the cutting-edge technical knowledge needed to transform manufacturing to create better, smarter, and more sustainable products. Serving as a physical and digital collaboration hub, it will support companies in their missions to digitise, innovate, and grow. It will become a driving force in the evolution of Manufacturing 4.0.

Driving stronger collaboration with open innovation

Today’s manufacturing supply chains are under enormous strain in the face of a diverse range of threats from global trade wars, the ongoing pandemic, and rapid technological disruption. Due to these factors and others, supply chains are becoming ungovernably large and complex to the point their sustainability and efficiency are being called into question.

There has never been a greater need for interconnectivity across these supply chains. But it’s not all about the integration of an increasingly disparate array of computing infrastructures. It’s as much about the integration of people and process through strong collaboration and mutual support across the public and private sectors. Simply put, this is the only thing that can sustain success during the uncertainties of the years to come.

Manufacturing means employment, and to secure its future, we need to build a workforce that’s educated and skilled in areas like AI and smart automation. These new skills must be in balance, along with gender equality, to become a comfort zone for future generations of engineers.

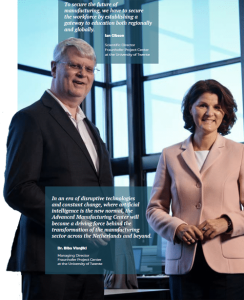

– Biba Visnjicki, Managing Director at the Fraunhofer Project Center

The AMC will not be a closed ecosystem, but an open innovation hub to drive digital transition in a world where science becomes business. It will serve as a point for solutions across the manufacturing sector by bringing in experts across a wide range of disciplines from around the world. This will include collaboration with hardware and software solution providers, and introduce a place where SME manufacturing companies, scaleups, and startups can develop, learn, and train.

Rapid growth and open innovation is at the heart of everything the Fraunhofer Project Center stands for. As such, the AMC will be the first of three buildings planned for Kennispark Twente, forming a major high-tech cluster to support the region.

Raising recognition for the Dutch manufacturing sector

With the exceptional knowledge and experience of key experts at the University of Twente, the Fraunhofer Project Center will be able to use the AMC as a conduit for knowledge transfer, open innovation, and applications research. This will allow the center to liaise with businesses in the manufacturing sector across the Europe to develop pathways toward smarter industry.

The AMC will drive greater recognition for manufacturing firms in the region by providing the resources necessary to innovate at scale across Europe. Moreover, with the assistance of the Fraunhofer Institute for Production Technologies (Fraunhofer IPT) in Germany, it will be well-positioned to further expand as an open innovation center with international recognition. Ultimately, the AMC will bring us the first international center for advanced production in the Netherlands.

Building a bridge between education and Manufacturing 4.0

It’s often claimed that technological development will claim more jobs than it creates. In reality, the opposite is true. In many sectors, especially manufacturing, education has been unable to keep up with the rapid evolution of technology. Manufacturers across Europe are struggling to fill job vacancies that require unique skillsets that were simply unheard of just a decade ago. Employers are now casting a wary eye on the future in a time when it’s near impossible to tell what that future may bring.

The lack of a suitably skilled workforce is now seen as one of the biggest challenges leading up to the fourth industrial revolution. But where there’s a dearth of important skills, there are also opportunities – a chance to innovate, reskill, and prepare for the many unknowns that the future holds. As has always been the case, manufacturing means employment, and innovation throughout the sector will continue to open up more job opportunities for those skilled in new and emerging areas like smart automation and artificial intelligence.

That is the vision of the Advanced Manufacturing Center, which will integrate education and manufacturing. The coming generations of engineers will depend on our open innovation center, and others like it, for developing the new skills and capabilities needed to propel the rise and success of Industry 4.0. It will achieve this through development programs that combine physical, hands-on learning experiences with the scalability of online learning. All the while, it will strive to resolve the gender imbalance across the sector and mitigate the various other adverse societal and economic effects of this constantly changing environment.

Our mission is to help guide the manufacturing sector through the tough choices to come using a combination of expert knowledge and cutting-edge technology. In doing so, it will encourage life-long learning by doing.

We must develop a global consensus on how new technologies, such as artificial intelligence and additive manufacturing can enable rapid digitisation.

– Profession Ian Gibson, Scientific Director at the Fraunhofer Project Center

Powering digital growth with emerging technologies in Manufacturing 4.0

Digital technologies have advanced at a pace many SMEs have struggled to keep up with. Concerns around things like information security, reliability, and the skillsets required to deploy and maintain these systems have long been barriers in the way of innovation. Disruptive new and emerging solutions like artificial intelligence, autonomous robotics, augmented reality, and the Internet of Things present new risks and opportunities alike, especially in times when the future of many firms is facing the heavy burden of economic uncertainty.

Above all, the future of manufacturing will revolve around artificial intelligence which, in turn, will give rise to highly advanced cyber-physical systems and a new era of automation. AI is undoubtedly the new normal, and the key driver of the fourth industrial revolution.

Thanks to AI-driven automation and insights, we will be able to power sustainable and extremely reliable industrial control systems, and automate entire production lines. This will ultimately allow us to build better products and optimized processes that increase efficiency and safeguard our supply chains. We’ll be able to put real-time insights to work, develop cloud solutions for the seamless integration of data and collaboration, and rapidly scale and adapt to the changing needs of businesses and their customers.

The AMC’s mission is to enable the fast transition toward the digitization of manufacturing by breaking down the barriers to innovation with knowledge, education, and collaboration. This synthesis will bring together machine builders, producers, engineers, and product developers under the umbrella of a universal approach to digital transformation