COOLL DEVELOPS SUPERHYBRID:

a thermally driven heat pump based on the principle of adsorption

Technology

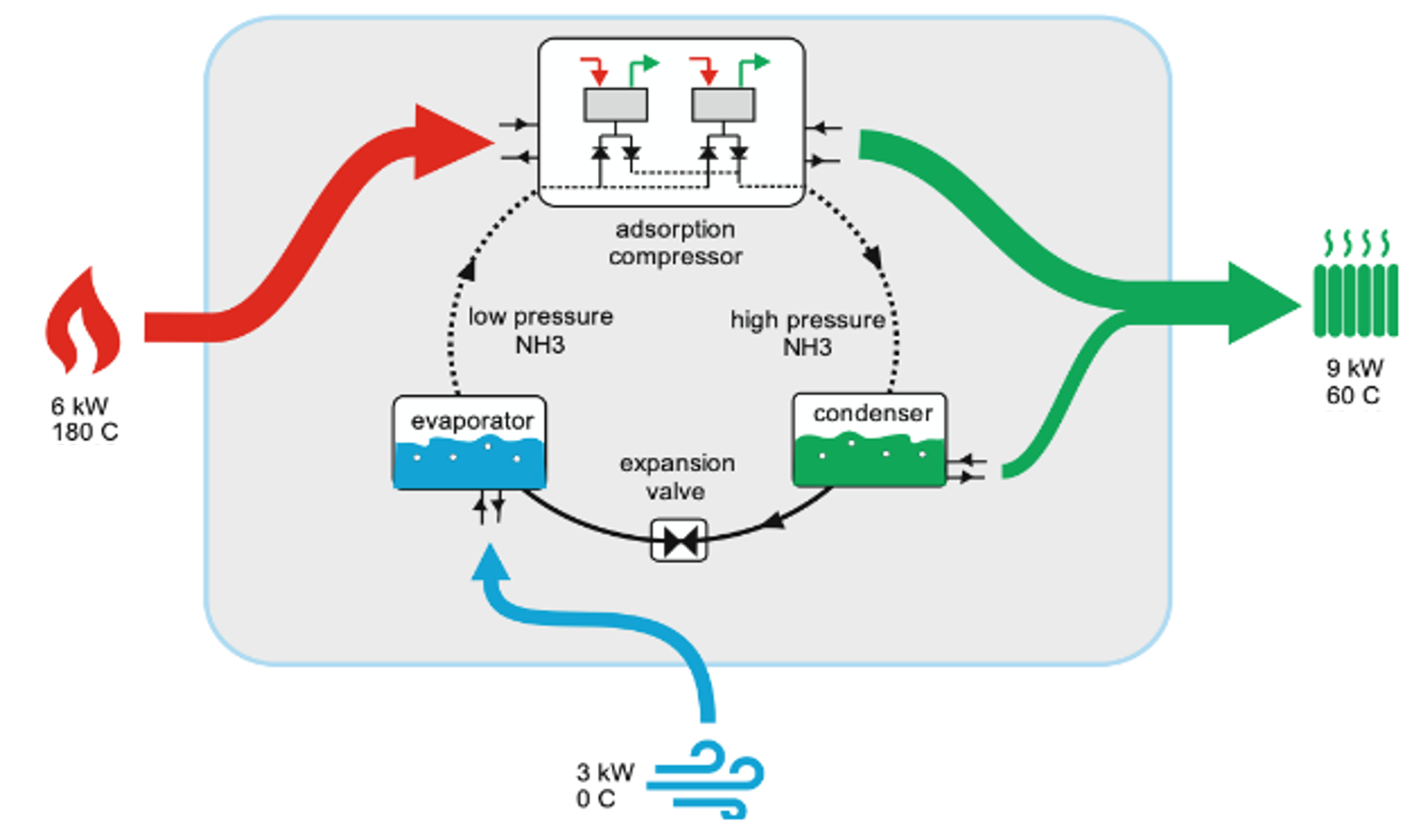

Cooll’s SuperHybrid contains a similar continuous cycle to as a normal electric heat pump. However, compression of the refrigerant now takes place with a heat-driven adsorption compressor instead of an electrical-mechanical compressor. The required heat comes from a burner, which can be driven by both natural gas and sustainably generated (hydrogen) gas.

The adsorption compressor consists of two pressure vessels filled with high-quality activated carbon, which are heated and cooled cyclically. A complete cycle takes about 10 minutes. During heating of a pressure vessel (up to approximately 180°C), the refrigerant is pressed out of the adsorption material under high pressure and transferred to the high-pressure side of the heat pump. The refrigerant then condenses and releases its heat to the heating circuit of the house (for example at 60 °C), after which the pressure of the refrigerant is lowered via the expansion valve. The refrigerant evaporates again at a low temperature (for example 0 °C of the outside air) and thus absorbs energy from the cold environment. The refrigerant then flows to the other pressure vessel at the initial temperature (60 °C in this example), adsorbing the refrigerant back into the adsorption material. After about 5 minutes, the function of the two pressure vessels reverses, creating a cyclic process. Compared to a standard central heating boiler, the gain is in the extra heat that becomes available via the evaporator and the condenser.

Cooperation with Fraunhofer

Cooll has been working with various Fraunhofer institutes for several years. The collaboration started through an EFRO project, during which the FIP-AM@UT supported Cooll with design and production issues around the adsorption compressor. The Fraunhofer IPT, IWS and IWU institutes also contributed to this. Fraunhofer ISE also played a role, among other things by studying the market potential of the Cooll heat pump and measuring the performance of Cooll’s heat pump in the accredited test lab in Freiburg. Cooll and Fraunhofer ISE also participate jointly in the Thermally Driven Heat Pumps working group of the European Heat Pump Association (EHPA). The collaboration with Fraunhofer is therefore important to Cooll for several reasons

Relevance for energy transition & hydrogen developments

The International Energy Agency (IEA) expects that although the share of renewable energy sources will increase in the coming years, the use of fossil fuels for heating will remain substantial over the same period. (https://www.iea.org/fuels-and-technologies/heating)

This means that a large share of European buildings, especially somewhat older ones, will continue to rely on heating sources other than electric heating in the near future. In order to reduce CO2 emissions in the built environment as soon as possible and to facilitate the transition to CO2 neutrality, a solution is needed that

(1) directly reduces CO2 emissions,

(2) can be applied at low cost in a wide variety of buildings, and

(3) can be powered by both conventional and renewable non-electric energy sources to be future-proof.

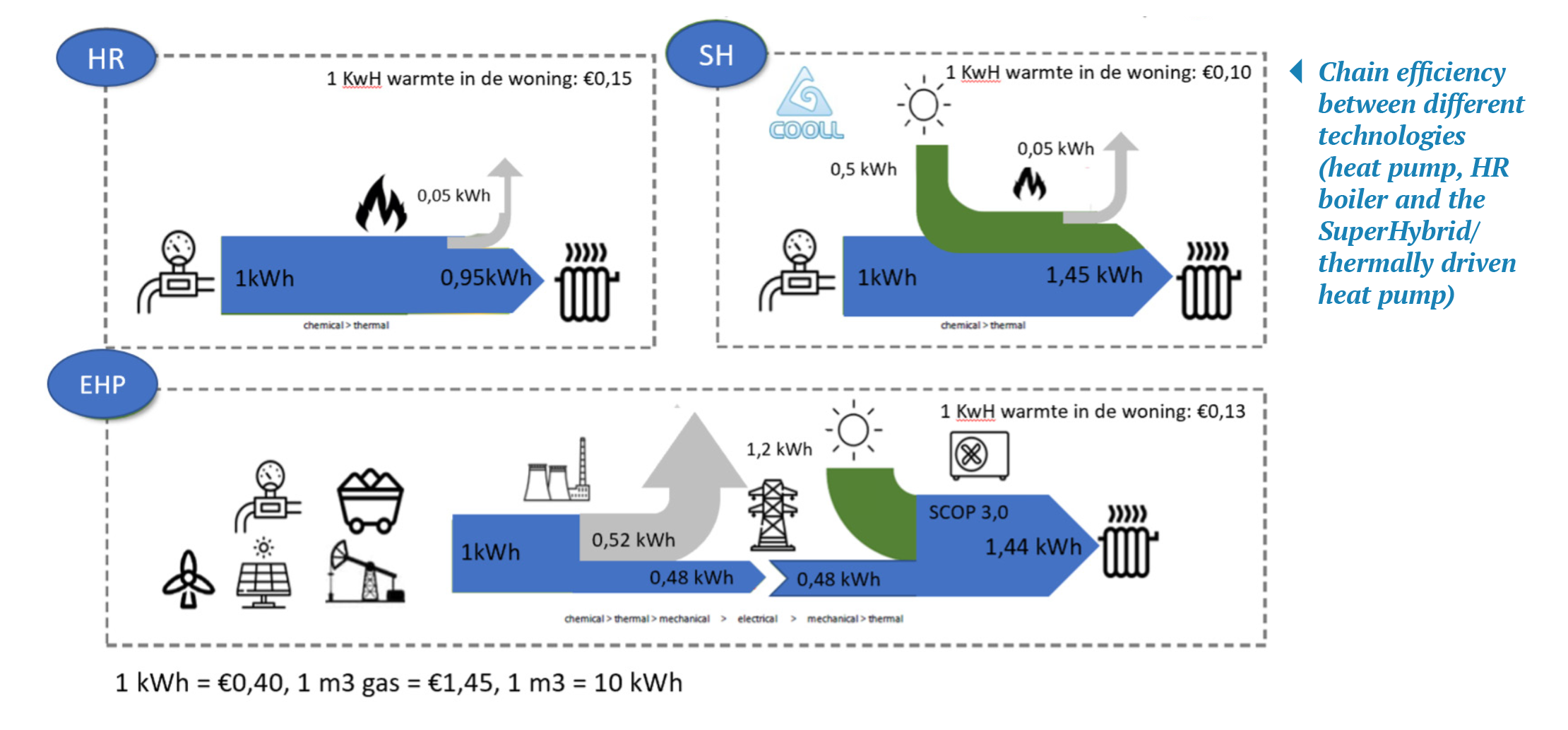

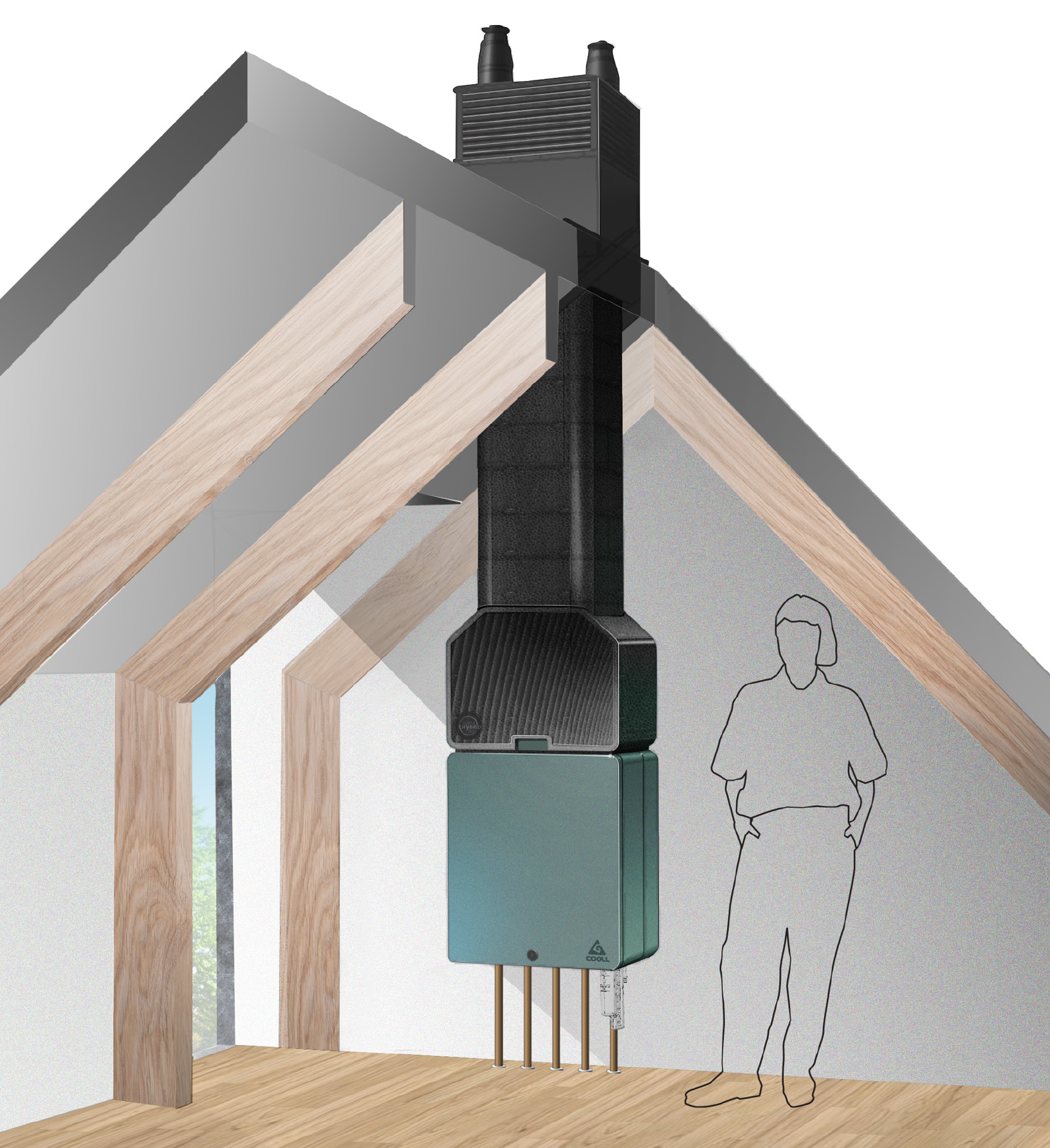

The EHPA and the European Heating Industry (EHI) issued a report on thermally driven heat pumps (https://www.ehpa.org/publications/reportthermally-driven-heat-pumptechnology/) in 2022. This report describes the relevance of thermally driven heat pumps and the role they can play in helping to achieve the climate goals. In specific terms, the SuperHybrid from Cooll can save at least 30% on (green) gas consumption compared to a central heating boiler, without the need for increased electricity consumption. In addition, the product is easy to install on the spot of a central heating boiler and no noisy outdoor unit is needed.

This saving also applies if green gas or hydrogen is used, which means that when applying this technology, less sustainable gas (and therefore storage and buffer capacity) will be needed to be able to supply a residential area with hydrogen, for example. This will increase the feasibility of various hydrogen projects, which are still in the pilot phase.

Current phase & future

Making a product market-ready with fundamentally new technology takes years. Cooll’s technology has been developed and tested using a series of prototypes with increasing TRL levels. After various lab setups that demonstrated efficiency, among other things, a number of functional models have been built that have been tested in real life environments in recent years.

At the moment, some of these devices are also being used in the GROHW-2 project where an energy system with hydrogen generation, buffering and offtake is being demonstrated (https://

grohw.nl/). Cooll’s heat pumps are used here to heat the Apparatengebouw building at the Gasfabriek in Deventer by mixing 30% hydrogen into natural gas. In parallel, Cooll is working on a drive suitable for 100% hydrogen and the production of the first series of SuperHybrids has recently started. After obtaining the necessary certification, these heat pumps will be tested in various homes in 2023.

Cooll expects that the multiple patented SuperHybrid technology will play an important role in the energy transition for the built environment in the coming years. Due to the substantial savings on natural gas, green gas or hydrogen, the SuperHybrid is a no-regret sustainability solution that does not place a heavier burden on the electricity grid. By 2025, Cooll expects this technology to be available to consumers. Cooll works exclusively B2B.