Room heating and cooling systems account for a significant portion of global electricity consumption, with traditional vapour compression refrigeration systems leading the industry for decades. While effective, these systems are energy-intensive and have considerable environmental impacts. The need for more energy-efficient and eco-friendly alternatives has spurred interest in magnetic heat pump technology, which uses the magnetocaloric effect. Studies show that these systems can be 10 to 20% more energy-efficient than traditional compressor-based systems. However, the high cost of magnetic heat pumps remains a barrier to their broader adoption.

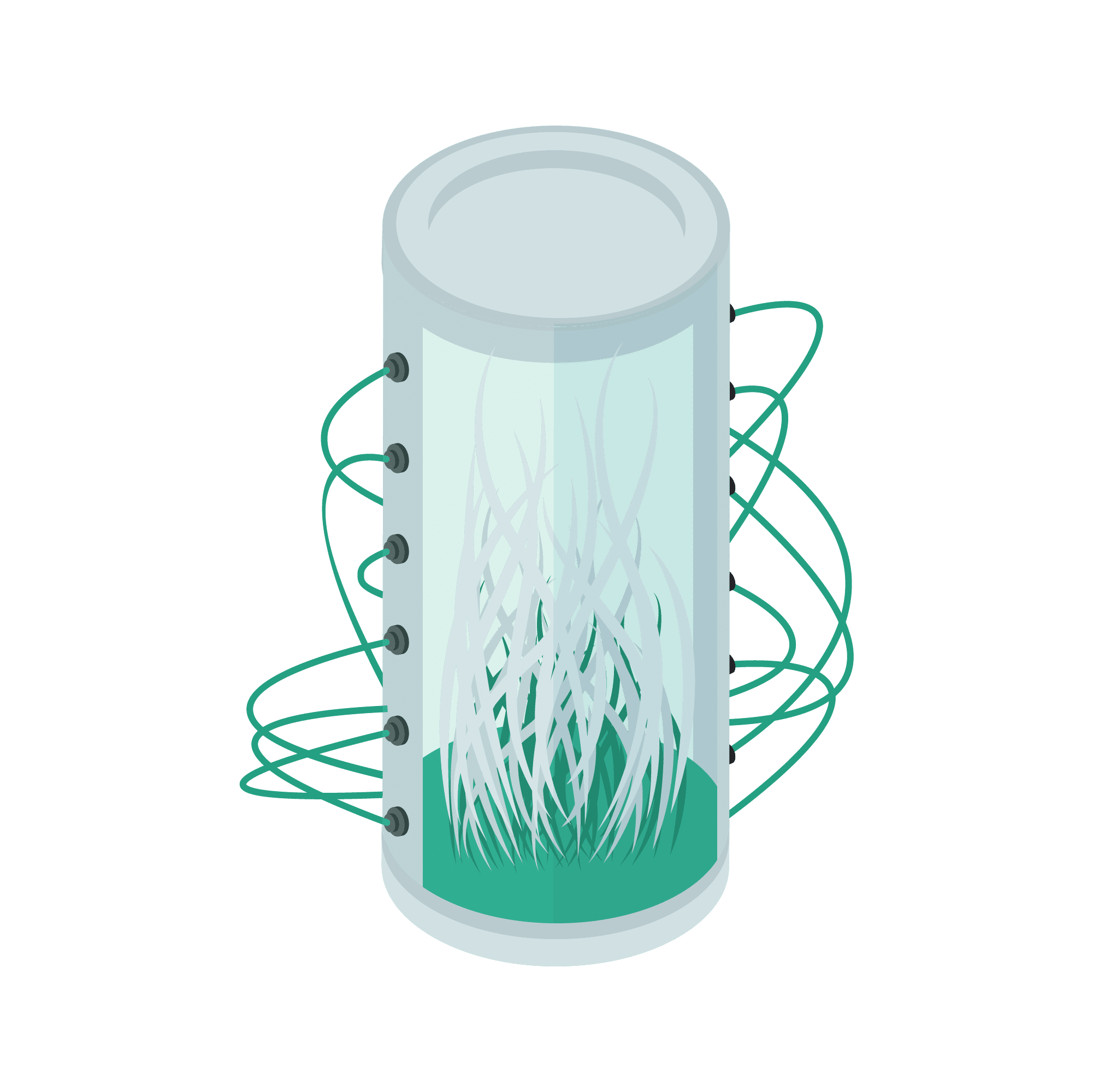

The MagHump project, in collaboration with Technische Handelsonderneming Nederland BV (THN), is focused on reducing these costs by innovating the design and manufacture of regenerators—crucial components in magnetic heat pumps—using liquid metal as a heat transfer fluid. The regenerator’s mass directly influences the cost of the permanent magnet assembly, the most expensive part of the system. By using liquid metal, the heat transfer process can be significantly accelerated, reducing the regenerator’s mass and, consequently, the amount of permanent magnet material required. This could lower overall system costs by 20 to 30%.

MagHump aims to develop the optimal regenerator geometry and establish a sintering process for manufacturing. Rigorous quality checks will ensure the manufactured regenerators meet high standards. The project will also measure and analyse the thermo-magnetic performance of the regenerators to validate their efficiency.

Through these innovations, MagHump seeks to make magnetic heat pumps more cost-effective and accessible, offering a sustainable solution for room heating and cooling with significant energy savings and environmental benefits.