Embracing Transparency: Understanding CSRD and its Impact on the Manufacturing Industry

Sustainability is no longer just a buzzword but a business necessity. Dutch manufacturing companies are increasingly aligning their operations with global standards for environmental, social, and governance (ESG) reporting. Companies in the Netherlands and across Europe are being shaped by a new regulation called the Corporate Sustainability Reporting Directive (CSRD).

What is the CSRD?

The CSRD is a more comprehensive and standardized approach to sustainability reporting. It brings sustainability reporting on par with financial reporting, ensuring that companies disclose reliable and comparable data on their ESG impacts. This directive is not just a formality; it’s a move towards transparency, accountability, and ultimately, a more sustainable future.

Why Does CSRD Matter to Dutch Manufacturing Companies?

More than an obligation, companies in the Netherlands will benefit from staying on top of the curve on the CSRD requirements. Some of the benefits to consider are:

- Enhanced Transparency: The CSRD mandates a detailed disclosure of sustainability-related information, enabling stakeholders, including investors, customers, and the general public, to make informed decisions based on a company’s ESG performance.

- Risk Management: By comprehensively assessing and reporting on sustainability matters, companies can better identify, manage, and communicate their ESG risks and opportunities.

- Competitive Advantage: Companies that adeptly integrate CSRD into their operations can enhance their brand reputation, attract sustainable investments, and meet the increasing demand from consumers for ethically produced goods.

- Regulatory Compliance: With the CSRD set to replace the existing Non-Financial Reporting Directive (NFRD), adherence is not optional. Dutch manufacturing companies are obliged to meet these new reporting standards or face the risk of non-compliance.

Preparing for CSRD: A Roadmap for Dutch Manufacturers

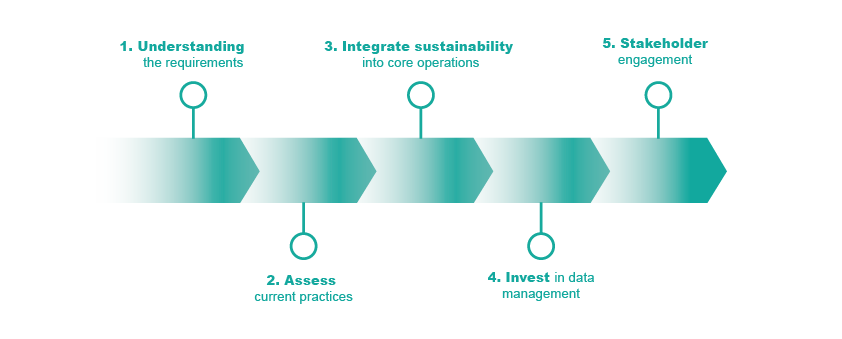

Dutch manufacturing companies can address the CSRD by following these 5 steps:

- Understand the Requirements: Companies need to familiarize themselves with the specific CSRD requirements, including the scope, reporting framework, and disclosure standards.

- Assess Current Practices: Evaluate current sustainability reporting practices and identify gaps that need to be addressed to comply with CSRD.

- Integrate Sustainability into Core Operations: Sustainability should be a core consideration in decision-making processes, reflecting in the company’s strategy, risk management, and operational practices.

- Invest in Data Management: Robust systems for collecting, managing, and reporting sustainability data will be crucial. This might require investments in technology and expertise.

- Stakeholder Engagement: Engage with stakeholders, including employees, customers, suppliers, and investors, to understand their expectations and communicate the company’s sustainability performance effectively.

The Road Ahead

For Dutch manufacturing companies, the CSRD is more than just a regulation; it’s a catalyst for transformation towards a more sustainable, resilient, and future-proof business model. By embracing the principles of transparency, accountability, and sustainability, companies can not only comply with the CSRD but also drive positive change, fostering a sustainable future for all. This is an opportunity for Dutch manufacturers to lead by example, showcasing their commitment to sustainability, and setting new benchmarks for the industry. The future is transparent.

Do you want to know how sustainability can be incorporated into your organisation? Contact us!