A ROADMAP FOR HIGH-TECH MANUFACTURERS

In the dynamic realm of hightech manufacturing, companies producing industrial products must balance innovation and sustainability. With the European Union (EU) spearheading ambitious net zero commitments, high-tech (and indeed all) manufacturers must strategically align with regulatory mandates while fostering sustainable practices. Understanding the essence of net zero, the increasing pressure on companies to act, and strategic pathways for high-tech manufacturers of industrial products is crucial for navigating this transformative journey.

What is Net Zero?

Net zero represents a milestone for organisations committed to environmental stewardship. It signifies achieving a state where greenhouse gas (GHG) emissions are significantly reduced and any residual emissions are offset through carbon removal techniques. This encompasses emissions not only from internal operations but also throughout the entire value chain, spanning manufacturing processes, supply chain logistics, and product lifecycle management.

The Imperative Intensifies

The urgency behind the net zero agenda is underscored by the escalating impacts of climate change. At the heart of global efforts to address this crisis lies the Paris Agreement, a landmark international treaty adopted in 2015. Signed by 197 nations, including major emitters such as the United States, China, the European Union, and India, it aims to limit global temperature rise to well below 2°C above preindustrial levels, with a more ambitious target of 1.5°C. This ambitious goal is crucial for safeguarding the planet from the most devastating impacts of climate change, including extreme weather events, sea-level rise, and biodiversity loss.

The Paris Agreement sets specific targets for reducing greenhouse gas emissions, including carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), which are the primary contributors to global warming. By limiting these emissions, it aims to mitigate the adverse effects of climate change and protect the environment for future generations.

Recent breaches of the 1.5°C threshold serve as stark reminders of the urgency to curb emissions. The devastating consequences of climate change are already being felt worldwide. From unprecedented heatwaves and wildfires to destructive hurricanes and floods, the impacts are evident. Swift and decisive action is essential to mitigate these impacts and secure a sustainable future for generations to come.

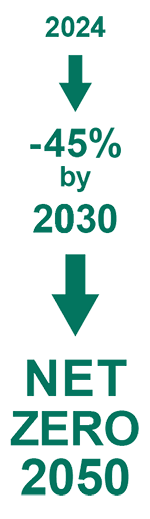

To meet the goals outlined in the Paris Agreement, drastic reductions in greenhouse gas emissions are necessary. Emissions must be slashed by 45% by 2030, with the ultimate objective of achieving net zero emissions by 2050. This requires a fundamental transformation of our energy systems, industries, and lifestyles, as well as unprecedented cooperation and commitment from governments, businesses, and individuals worldwide.

Stakeholders across the board, including investors, customers, and regulators, are increasingly scrutinizing companies’ climate commitments. Supply chain partners are integrating emission reduction targets into procurement strategies, while regulatory frameworks such as the Corporate Sustainability Reporting Directive (CSRD) in the EU are imposing stringent reporting requirements. As the pressure mounts for companies to align with the objectives of the Paris Agreement, those that fail to take meaningful action risk falling behind in an increasingly climate-conscious world.

Crafting a Strategic Response

For high-tech manufacturers of industrial products, navigating the path to net zero requires a comprehensive and proactive approach. Let’s envision a scenario of a high-tech manufacturer specializing in a range of industrial products, from parts to advanced finished products.

![]()

Clean Energy Adoption

Transitioning to renewable energy sources, such as solar or wind power, for manufacturing facilities is paramount. Implementing energy-efficient technologies and optimizing production processes can further minimize carbon footprint.

![]()

Sustainable Materials

Embracing eco-friendly materials and manufacturing processes can significantly reduce environmental impact. Exploring alternatives to traditional materials, such as recycled metals or bio-based composites, promotes sustainability without compromising quality.

![]()

Circular Economy Initiatives

Implementing circular economy principles, such as product refurbishment and remanufacturing programs, can extend product lifespan and reduce waste. Designing products for modularity and upgradability fosters resource conservation and enhances sustainability.

![]()

Supply Chain Collaboration

Collaborating with suppliers committed to sustainability fosters resilience and transparency throughout the supply chain. Establishing environmental criteria for suppliers and promoting responsible sourcing practices drive positive change across the industry.

![]()

Carbon Offsetting and Innovation

Investing in carbon offset projects, such as reforestation or carbon capture technologies, can help neutralize residual emissions. Concurrently, fostering innovation in carbon capture and utilization (CCU) technologies contributes to long-term sustainability and resilience.

Embracing the Future

The transition to net zero presents high-tech manufacturers of industrial products with both challenges and opportunities. By embedding sustainability into core business practices, companies can mitigate climate risks, drive innovation, and enhance stakeholder trust. As catalysts for industrial progress, high-tech manufacturers have the potential to lead the charge towards a sustainable future, reshaping industries and redefining corporate responsibility in the 21st century.