We have all heard of Artificial Intelligence, commonly referred to as AI. Every day we experience the advantages of AI through daily technological interactions, whether it is the navigation system suggesting a faster route based on real-time traffic data, smart home devices automating room temperature and energy consumption, or virtual assistants providing personalized product recommendations based on your location.

Similarly, sustainability has been rising as a trending topic for the last decades, making it increasingly challenging to

pinpoint its impact on our daily lives.

With the general understanding that sustainability is all about resource efficiency and optimization, the overlap between AI and sustainability starts to become more apparent. Faster routes often signify less fuel consumption, automated temperature control devices can help use energy more efficiently leading to cost savings, and getting personalized product recommendations from local suppliers can help reduce the footprint associated with product transport. These are only small examples of how AI is helping us become more sustainable in daily life.

What is sustainable manufacturing?

Sustainability is generally defined as “development that meets current needs without compromising the ability of future generations to meet their own needs”. In manufacturing, this translated to “manufacturing that meets current needs without compromising the ability to continue producing goods for future generations”.

In the context of sustainability, manufacturing is one of the areas that has much to gain from sustainable practices. In the Netherlands, for instance, 27,83% of emissions come from manufacturing industries and construction¹. Sustainable manufacturing involves leveraging rising technologies to regulate the energy consumption of manufacturing processes or tracking goods through the supply chain to optimize routing and warehousing needs. If done right, resource optimization and supply chain efficiency will result in cost savings. With the regulatory push driving more SMEs to investigate sustainability, AI might just be the key enabler for a greener manufacturing industry.

What is AI in manufacturing?

In the last decades, manufacturing revolutions have been driven by the introduction of digital technologies for performing complex and resource intensive tasks in the most efficient ways possible. The digital evolution is not just about automating conventional manufacturing processes but also about comprehensive integration of intelligent systems that enhance decision making capabilities, optimize production workflows, and support stakeholders and production managers in driving innovation. By modernizing manufacturing processes through AI technologies, the efficiency and quality of production are improved.

Advanced processes generate vast volumes of data, which makes intelligent manufacturing possible. This data serves as a rich input source for AI models, enabling them to make informed and smart decisions. Additionally, having access to computing power, along with the repeatability and reliability of performance, further supports this advancement.

The overlap between AI and sustainability in manufacturing

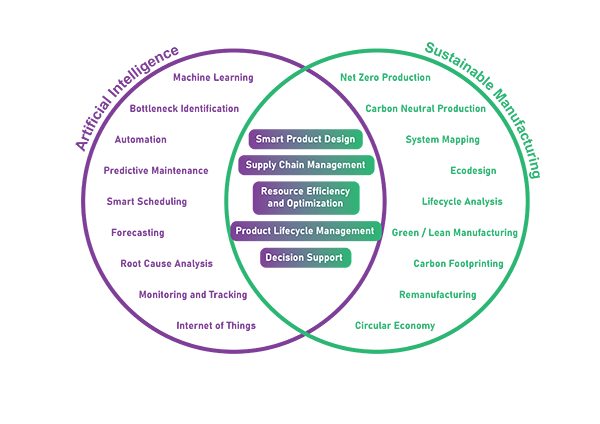

The concepts of AI and Sustainability are not often mentioned together, yet they significantly overlap in methodologies and goals. AI provides the tools and techniques, while sustainability sets the objectives and direction. When sustainability focuses on measuring impact and identifying areas of opportunity, AI acts as the medium for processing and analyzing data.

Among many concepts associated with each discipline, we have identified 5 core concepts where the overlap is pronounced:

![]()

Smart Product Design

![]()

Supply Chain Management

![]()

Resource Efficiency and Optimization

![]()

Product Lifecycle Management

![]()

Decision Support

Core Concepts Exemplified

In this section, the five core concepts are illustrated by examples to demonstrate their potential in the manufacturing industry.

1. Smart Product Design allows product engineers to iterate over product concepts that utilize new generation materials, advanced technologies, and user-centric approaches meeting key functional requirements and environmental, social, and economic standards.

Example 1: Generative Design for Aerospace Applications

An aerospace component manufacturer relocated to a new manufacturing hall further from their material suppliers. To enhance operational independence, the decision was to explore alternate design and manufacturing methods, such as 3D printing, for some of their components. By leveraging AI-driven generative design, several key benefits have been achieved: enhanced design innovation, improved manufacturing flexibility, minimized warehousing needs by producing components on demand, significantly reduced material usage, and consequently lowered fuel consumption in the final aerospace application.

2. Supply Chain Management enables procurement specialists to manage goods, information, and finances to maximize value and efficiency while minimizing lead times.

Example 2: Cold Storage Demand Forecasting for Medicine

A pharmaceutical manufacturer delivers life-saving medicine requiring cold storage. To mitigate the costs and risks associated with cold storage, the manufacturer uses an AI-driven demand forecasting method to predict demand fluctuations, purchase raw materials in advance, and coordinate optimal transport routes in real-time, ensuring minimal time to market.

3. Resource Efficiency & Optimization involves strategically allocating and managing resources—including time, money, materials, and labor across various processes to achieve specific goals. Efficiency, on the other hand, focuses on minimizing resource usage while maintaining high standards of quality and productivity.

Example 3: Retrofitting an Aluminum Furnace

An aluminum manufacturer used an AI-driven control system to transition from natural gas and AC induction heating to a combination of natural gas (NG) and DC induction heating. The AI system optimizes electricity use by independently switching energy sources based on production demand, energy cost, and grid stability, reducing the environmental impact with minimal investment and production disruption.

4. Product Lifecycle Management: Integrates people, processes, business systems, and information to manage the product portfolio across all stages from raw materials to disposal.

Example 4: Scenario-based Lifecycle Analysis for Cardboard Manufacturing

A cardboard manufacturer shifted to producing only recycled boxes after increased demand for environmentally friendly products. They developed an AI algorithm to analyze the environmental impact of various sourcing scenarios. The analysis enabled them to source recyclate2 from their own production waste, local waste, and certified suppliers ensuring a steady supply of fully recycled boxes while reducing production waste and local waste.

5. Decision Support: Provides real-time insights on production processes, facilitating datadriven strategic decisions.

Example 5: Polymer Process Emission Monitoring and Detection

A polymer processing manufacturer uses an AI-driven Emission Management System (EMS) to reduce the frequency of leak detection tests. This system monitors unwanted volatile organic compounds (VOCs) and other gases in real-time. The EMS helps identify hotspots and calculate the CO2e3 of their process. This enabled the discovery of a specific solvent that emitted more VOCs than anticipated and decided to switch to a water-based solvent that operates at lower temperatures, reducing both emissions and energy consumption. The alternate solvent option allowed manufactured products to be sold at a lower cost and have a market advantage over competitors.

Conclusion

When it comes to sustainable manufacturing there is no onesize-fits-all approach. Sustainability poses unique challenges for each manufacturer, and gathering a holistic overview of the company, market, products, and processes is critical to determine sustainability opportunities and the AI tools to support it. By leveraging AI as a technological enabler, manufacturers can develop sustainable strategies that are not only effective but also adaptable to their needs.

The five concepts of smart product design, supply chain management, resource efficiency and optimization, product lifecycle management, and decision support are inherently interconnected. Each plays a vital role in creating a sustainable manufacturing ecosystem, where AI-driven insights can lead to significant improvements in efficiency and environmental impact. By embracing AI and sustainability, manufacturers are ready to tackle the most pressing environmental issues in manufacturing, contributing to a better future.

1: The Netherlands – Countries & Regions – IEA. (2023)

2: Recyclate: recycled material to be processed into a to new material or product

3: CO2e: metric used to compare the emissions of various greenhouse gases (GHG) based on their global warming potential (GWP) relative to Carbon Dioxide (CO2).