As sustainability becomes more important for businesses, remanufacturing offers a valuable solution. Beyond helping the environment, remanufacturing can also lead to cost savings and new revenue opportunities. Companies can combine Design for Manufacturing principles with circularity strategies, such as remanufacturing, to maximise product value, improve profitability, and extend the lifecycle of their products. Early design decisions, critical tools and modern technologies are essential to leveraging remanufacturing’s full potential.

Transitioning to a circular economy means designing products for longevity, repair, and reuse. It’s not just about reducing waste; it’s about creating a closed-loop system where materials and components keep their value for as long as possible. This involves using advanced design techniques to ensure products can be easily disassembled and remanufactured, reducing the need for raw materials and lowering overall production costs.

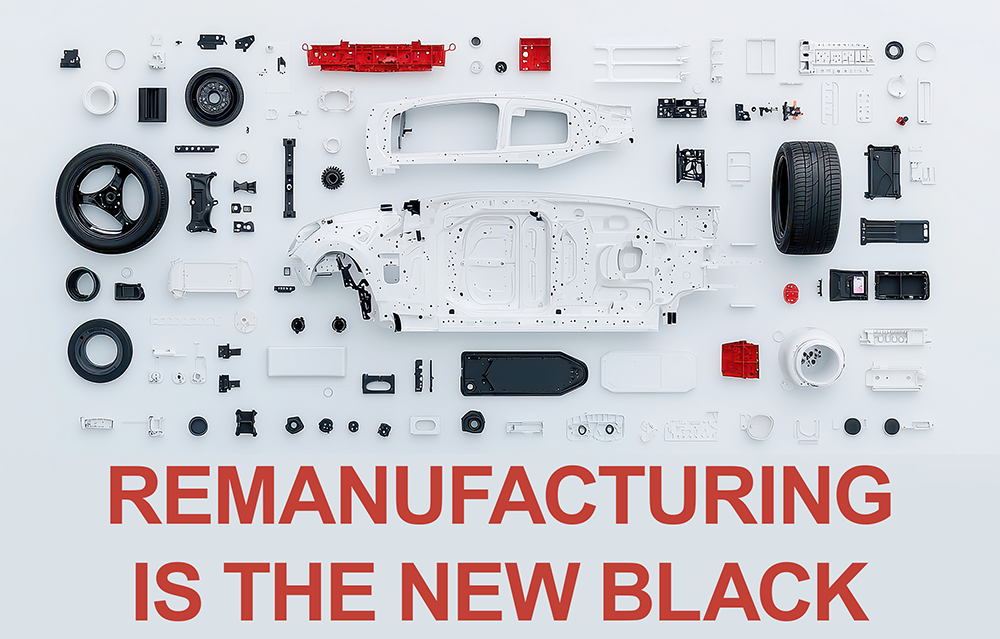

Remanufacturing is the process of restoring a used product to a like-new condition. Unlike recycling, which breaks products down into raw materials, or refurbishment, which addresses minor repairs, remanufacturing involves a more comprehensive overhaul. It includes disassembling the product, cleaning it, replacing worn parts, and reassembling it, often with upgrades – and quality guarantee.

Industries such as automotive, electronics, and industrial machinery are particularly suited to remanufacturing due to the complexity and high cost of their products. Designing products for both manufacture and remanufacture helps save materials, reduce waste, and enhance competitiveness.

Designing for Remanufacturing

To fully take advantage of remanufacturing, businesses must think about it from the start. Design for Remanufacture (DfRem) is an approach where products are designed to be easily disassembled, repaired, and rebuilt. This makes the remanufacturing process faster, easier, and less expensive.

Early design decisions are crucial for a product’s remanufacturing potential. Companies should focus on key design elements such as:

allows individual parts to be replaced or upgraded without affecting the entire product. This is especially beneficial in sectors like electronics, where technology evolves rapidly.

is critical. Choosing durable materials that resist wear extends a product’s lifespan and reduces the need for replacement parts.

across product lines simplifies the remanufacturing process, reducing both inventory and operational costs.

Additionally, advanced tools such as the Modular Grouping Explorer (MGE) and Multi-Criteria Modularization help designers optimise products for remanufacturing by improving disassembly, reassembly, and lifecycle management.

By focusing on modular design, material selection, and standardization, businesses can make the remanufacturing process more efficient and cost-effective, ensuring longer product lifecycles and easier maintenance.

The Economic Benefits

The 2024 Bain & Company Global Machinery & Equipment report underscores the financial benefits of remanufacturing, revealing that it can cut production costs by up to 60%. This dramatic reduction is achieved through improved resource efficiency and decreased material consumption. By reusing parts and materials, companies can slash expenses while boosting their bottom line. This not only aligns with global sustainability goals but also enhances competitive positioning in an increasingly eco-conscious market.

A recent update from the European Commission’s Circular Economy Action Plan underscores the growing importance of remanufacturing in the circular economy. The Action Plan reveals that advancements in remanufacturing technologies are enabling higher-quality refurbishments and more efficient recycling processes. These developments are transforming old components into high-value products, challenging traditional notions of waste, and promoting a shift towards more sustainable production practices in the EU.

The Market Advantage

Several high-profile companies are demonstrating the tangible benefits of remanufacturing. For example, Caterpillar has integrated remanufacturing into its core strategy, turning old engines into new, high-performance products. This approach not only reduces waste but also provides Caterpillar with a competitive advantage by offering cost-effective solutions without compromising on quality.

Ford Motor Company is another notable example, implementing a remanufacturing programme for vehicle parts such as engines and transmissions. Ford’s commitment to recycling and remanufacturing supports its environmental goals and caters to a market increasingly focused on sustainability. By offering high-quality remanufactured parts, Ford proves that eco-friendly solutions can align with excellent performance.

Embracing remanufacturing comes with challenges. Companies must navigate complexities such as managing supply chains and maintaining consistent product quality. However, these obstacles are manageable. Effective communication about the benefits of remanufactured products and transparency in processes can help address consumer concerns and boost acceptance.