MODULARITY OF MANUFACTURING SYSTEMS FOR EFFICIENT PROTOTYPING

In the current market landscape, where product lifespans are shrinking and global competition is intensive, achieving a quick time-to-market is crucial to stay profitable. Fraunhofer IPT addresses this goal by concentrating on two key research areas: process development for new product manufacturing and modular manufacturing equipment designed for efficient prototyping. The research highlights modular production systems that cover the entire production lifecycle, from initial prototyping to high-volume mass production with aid of digitalization tools. A significant outcome of this these innovations is the Aachen Center for Optics Production (ACOP). This center helps companies adopt digitalization at Fraunhofer IPT, discover opportunities for added value in their production, and implement targeted solutions effectively. Through these initiatives, Fraunhofer IPT focuses on enhancing manufacturing processes in terms of time, energy, and cost, while also promoting sustainability.

Introduction to Glass Molding Technology

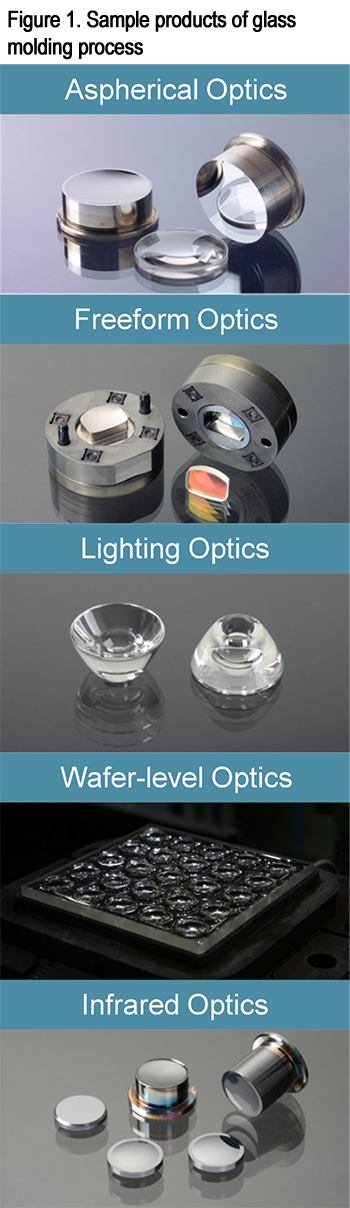

Complex optical geometries, such as freeform and aspheric shapes, are increasingly required in various industries such as automotive and medical. Glass molding is a replicative manufacturing technology that produces optical lenses with high form accuracy. This process involves molding a glass preform at elevated temperatures using precise tools, followed by cooling to achieve the final product. Sample products of this process are illustrated in Figure 1. However, process development often relies on trial-and-error methods, which are time-consuming and costly. Utilizing simulation tools like Finite Element Method (FEM) and Machine Learning (ML) can optimize manufacturing operations and facilitate efficient prototyping, enabling rapid iterations and reducing overall time and costs.

Challenges in Process Development

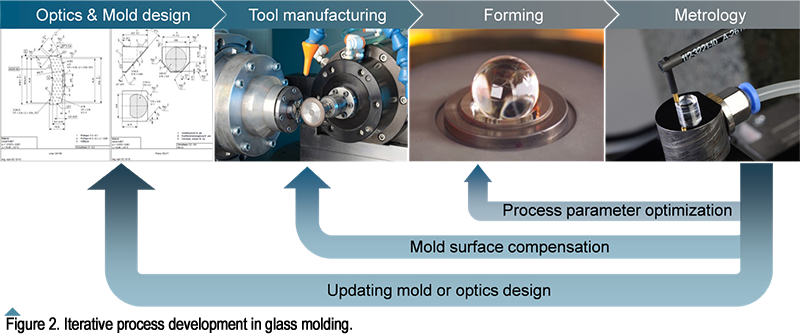

As shown in Figure 2, the traditional process development for glass molding begins with designing the optical component and mold geometry.

Later, ultra-precision methods are employed for tool manufacturing to meet surface finish requirements. Then, forming experiments are conducted to evaluate the glass’s behavior, and advanced metrology techniques are utilized to measure surface quality and optical properties of the molded glass. Depending on the resulting deviation, further adjustments to the molding parameters would be necessary or complex iterations such as mold surface compensation or even the mold redesign are required. This iterative approach ensures continuous refinement and adherence to high-quality standards in glass molding technology.

Moreover, there exists several challenges during process parameter optimization. Key parameters include determining the optimal molding temperature, which impacts glass viscosity, and establishing the pressing force and cooling rate. Moreover, selecting appropriate glass preforms and materials as well as mold tools is critical, as these choices greatly influence final product quality. Since glass is a viscoelastic material at molding temperatures, the process involves highly nonlinear thermo-mechanical concepts, resulting in a complex interaction of the process parameters, the selected materials, and sample dimensions. Without digital twin systems or advanced simulations, industries often rely on time-consuming manual trial-and-error experiments, which can be inefficient and resource-intensive.

FEM Simulation for Process Development & Optimization

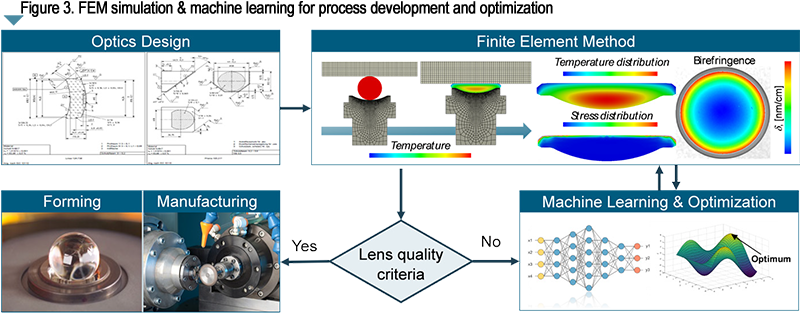

To overcome these challenges, FEM simulation is utilized in the process development at Fraunhofer IPT. FEM enables the modeling of glass behavior during the molding process, facilitating the identification of optimal process parameters tailored to specific designs. Through simulations, the ideal molding temperature, pressing force, and cooling rates can be determined to minimize defects while maximizing efficiency. Furthermore, machine learning and various optimization algorithms are incorporated for the optimization of process parameters.

FEM simulation plays a crucial role in designing glass preforms to ensure they meet the specifications for the final product. By evaluating different geometries, preform designs can be optimized for better flow characteristics and thermal performance. At Fraunhofer IPT, material characterization of glass is also a focus, utilizing the Generalized Maxwell Model, the Burgers Model, and the Tool-Narayanaswamy-Moynihan Model to capture its viscoelastic and structural relaxation behavior. Furthermore, simulations provide insights into mold design modifications, enabling refinement of mold geometry and material selections to enhance durability and overall performance. The iterative nature of FEM simulations allows for rapid prototyping and evaluation of new designs, significantly reducing the time and cost associated with physical trials.

Modular Manufacturing Equipment for Efficient Prototyping

For efficient prototyping, the manufacturing equipment needs to be developed simultaneously with the product development itself. This results in a high-risk development, because the manufacturing equipment needs to be adjusted continuously to the developed product. Therefore, the Fraunhofer IPT has developed a battle-proven strategy to challenge this problem and set up new production systems in a fast and reliably way.

In the early prototyping stage, it is crucial to divide the production process into defined sub-process and evaluate each sub-process individually. The individual sub-processes can be developed and permitted simultaneously, which can save a lot of time in the development. Furthermore, the subdivision allows changes in the product to only affect individual sub-processes, but not the entire design of the machine. Within these sub-process, functional modules are defined. They are designed to perform specific tasks such as machining, assembly, or inspection. Each module is a self-contained unit that includes all the necessary electrical, pneumatic, and mechanical components required to perform its designated function.

The main goal is to shift the complexity from a new developed machine towards smaller functional units. This guideline can be used to define a standard interface between the machine and the functional units, ensuring the use of different functional modules throughout the whole production cycle. When a sub-process is completed using a developed functional module, the whole process can be carried out by linking the sub-process. The solution for linking the processes should not affect the individual sub-processes. Production scaling is therefore only determined by the choice of how the individual sub-processes are linked (manual, semi-automated, automated).

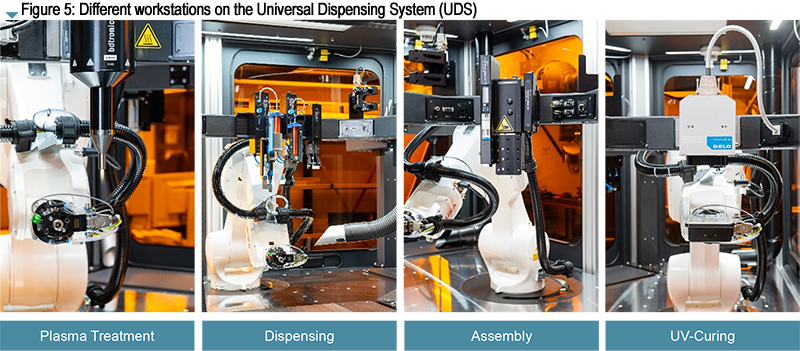

The Universal Dispensing System – UDS

An exemplary illustration of the development and integration of functional modules is the universal dispensing system – UDS, developed by the Fraunhofer IPT. This system comprises a series of modular processing stations, arranged in a 180° semicircle configuration around a multi-axis robot. The UDS has multiply workstations where sub-processes for adhesive assembly can be developed individually. The function of the robot is to accurately position the workpiece between the individual functional units. Therefore, exchangeable functional modules can be mounted and tested on each workstation.

With these exchangeable functional modules, the whole range of adhesive-assembly-processes can be evaluated and tested. The presence of a defined mechanical and electrical interface allows for the expansion and exchange of modules developed in parallel. The implementation of a suitable software interface permits the ‘plug and play’ of different functional units without the necessity for software adaptations. The machine is equipped with a free programming interface, which facilitates the development of diverse processes. Therefore, the concept of the “UDS” robotic cell has the potential to be adapted to the increasing complexity of modern production processes over the long term.

The multi-axis robot interlinks the developed sub-processes as it facilitates as the transportation of the workpiece from one functional module to the next. This allows for a quick and easy automated ramp-up of production. The ‘plug and play’ integration of functional units in a flexible and modular manner, while ensuring an efficient transfer system, ensures an efficient prototyping across various industries.