UNLEASHING THE POWER OF ADDITIVE MANUFACTURING

Additive Manufacturing (AM) represents more than a technological advancement; it redefines the way products are designed and created. To fully capitalize on the potential of AM, it’s essential to align the design process with the specific limitations and strengths of the chosen AM method. This makes a deep understanding of design principles critical to ensuring high-quality results. Design for Additive Manufacturing (DfAM) plays a crucial role, guiding designers to optimize their creations by taking advantage of AM’s distinctive possibilities.

DfAM is more than just making things with a 3D printer; it’s about reshaping how we think about design, pushing the boundaries of what’s possible, and ultimately transforming how we manufacture everything from everyday objects to advanced aerospace components.

The Foundations of DfAM

The journey into Design for Additive Manufacturing (DfAM) starts with a thorough understanding of the AM workflow, which helps clarify the designer’s role throughout the process. Unlike traditional manufacturing, which imposes constraints and predefined limitations on designers, AM transforms this paradigm by providing exceptional design freedom. It enables the creation of complex geometries and enhances material efficiency beyond conventional methods. This introduction to DfAM underscores the crucial integration of design innovation with manufacturing feasibility.

Opportunity VS. Constraint

Additive Manufacturing (AM) offers a wide range of possibilities, with each technology presenting its own set of constraints and opportunities. While traditional manufacturing methods often come with strict limitations, AM provides greater design freedom. However, this freedom requires a careful, disciplined approach. There are seven main groups of AM technologies, each with specific material requirements, layer thickness options, and support structure needs that can affect the final result. Engineers and designers need to understand and navigate these constraints to create designs that are both innovative and practical for manufacturing.

The AM Landscape

According to ASTM standards, Additive Manufacturing (AM) technologies are categorized into seven groups:

VAT polymerization

Material extrusion

Material jetting

Binder jetting

Powder bed fusion

Direct energy deposition

Sheet lamination

Currently, all commercial AM equipment falls under one of these categories, each offering a subset of unique techniques and demanding a tailored approach to design.

Strategies for Success

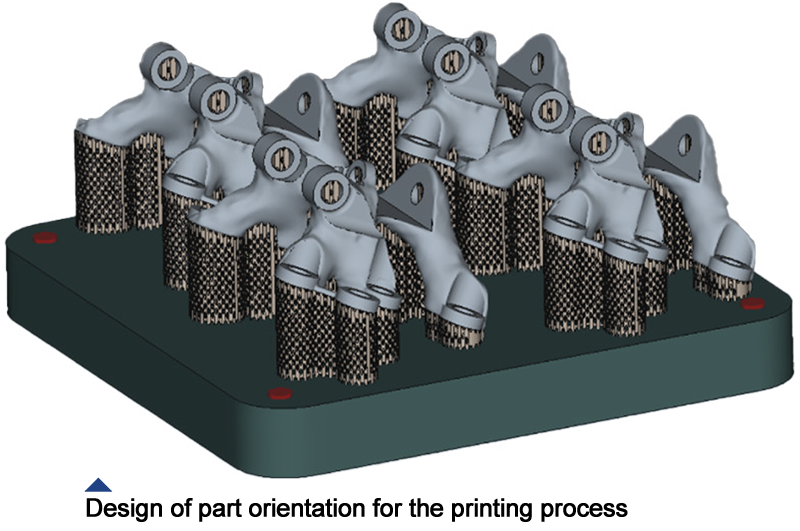

Achieving high-quality prints starts long before the printer is powered on; it begins in the design phase. One of the most critical decisions is material selection, as each AM technology supports different materials, each with unique properties that directly influence the performance of the final product. Choosing the right material is crucial, but equally important is how the part is designed to accommodate support structures, which stabilize the part during printing. The number, placement, and orientation of these supports significantly impact the economic, aesthetic, and functional outcomes of the print. Thoughtful design can minimize material usage, reduce post-processing time, and enhance the overall quality of the part. This is because the way a part is oriented during printing affects its strength and surface finish, while carefully optimizing layer thickness can reduce print time and improve mechanical properties. Warping and distortion are common issues, especially in larger parts, but they can be mitigated through strategies like bracing or adjusting wall thickness. It’s essential to address these factors early in the design process, especially before and during CAD modelling, as they can prevent costly post-processing and ensure that the final product meets the required specifications. These considerations only scratch the surface of the complex, geometry-dependent aspects that must be addressed before printing begins.

From Design to Print

When transitioning a part from a CAD model to a physical print, the digital file and its associated information significantly influence the final outcome. DfAM involves more than just creating a digital model; it requires a deep understanding of the printing process and how each design choice impacts the final product. Factors such as material selection, part orientation, support structures, and layer thickness are all interconnected, and each is crucial to the success of the print. Engineers and designers must adopt a holistic approach, considering not only the immediate requirements of the print but also how each decision will affect the entire manufacturing process. Anticipating and addressing potential issues during the design phase can be the key to a successful print, and using the right tools can make a significant difference.

The Power of Simulation

Simulation is a crucial tool that connects design with reality in AM. Advanced simulation software enables designers to predict and address potential issues such as warping, shrinkage, or stress concentrations before printing begins. This proactive approach not only saves time and resources but also improves the accuracy and reliability of the final product. Simulation tools assist in various aspects of printing, including optimizing slicing strategies, generating supports, and determining part orientation, ensuring compatibility with the chosen AM technology.

These tools streamline workflows, shorten time to market, and enhance overall efficiency. Real-time feedback on design changes ensures that parts are both manufacturable and optimized for performance and material usage. This capability is particularly valuable in industries such as aerospace, medical devices, and automotive, where precision and material efficiency are crucial.

Shaping the Future of Manufacturing

We are just at the beginning of exploring the possibilities offered by DfAM. Innovations such as multi-material printing and advanced software tools are poised to push the boundaries of design and manufacturing, creating a future where imagination sets the limits. While the potential of AM is vast, realizing it fully requires rethinking design with a clear understanding of both the limitations and capabilities of AM methods. DfAM represents more than a collection of techniques; it embodies a new design philosophy that encourages us to think differently, innovate boldly, and shape the future. For both experienced engineers and curious designers, the journey into DfAM presents endless opportunities to explore, experiment, and excel in this dynamic new field of manufacturing.