Artificial intelligence (AI) is rapidly transforming the landscape of design and manufacturing, offering opportunities for innovation and efficiency. In this interview, Stephen Hooper, Vice President of Design and Manufacturing at Autodesk, discusses the potential and risks of AI integration, the company’s strategic direction, and the transformative impact on product design and engineering.

For which company sizes is the use of AI sensible and economically viable?

There are key challenges today that affect companies of all sizes: skills gaps and labor shortages, a need to address sustainability, and of course the ever-present need to increase efficiency. In short, the world has a massive capacity problem that AI helps address, regardless of a company’s size. There are more things that need to be made and built than there are people, money, and material to make them. At Autodesk we consider AI an accelerant that can help address these challenges by helping a designer reach their true intent, as if they had the expertise of a senior assistant. Through language, sketches, previous designs, and other input methods, AI can help designers reach better outcomes faster than they would without it. If you consider AI a new technology that can augment creative processes, automate tasks that are necessary but mundane and repetitive, and analyze data to uncover inefficiencies, you can see that AI might fit and be economically viable for any company.

How can design and engineering benefit from AI in the future and what role does Autodesk play in these developments?

At Autodesk, we have been investing in artificial intelligence for over a decade. Today, Autodesk AI is available to augment creative problem-solving and exploration, automate tedious and repetitive work, and give individuals and teams access to powerful analysis tools to inform decision-making. In Autodesk’s annual State of Design & Make report, 66% of industry leaders predict that AI will be an integral part of their business within 2-3 years. They see AI as an essential tool for keeping up with demand, reducing error and waste, and accelerating efficiency. I believe that AI will operate as a co-pilot, enabling rapid exploration of initial concepts and helping to evaluate the implications of various design decisions. Partnering with AI in this way augments human capabilities and bandwidth, meaning professionals can work more effectively on more projects, thereby increasing capacity and driving down the cost of an individual project so that more projects can be completed.

How are AI functionalities integrated into Autodesk software?

Today there is a broad spectrum of AI-powered Autodesk tools. For Product Design & Manufacturing, we’ve had an AI capability in Autodesk Fusion called generative design for more than six years that enables designers to define the requirements of a manufactured part – what it needs to do, how strong it needs to be, what it should be made from, and so on — instead of drawing what it is and how it looks. In a matter of minutes, the AI-powered generative design takes all the designer’s requirements into consideration and offers dozens of suggestions that meet those requirements, while being as light and strong as possible.

Another key step towards integrating AI functionalities into our tools was our acquisition of BlankAI, a generative AI technology that enhances industrial design creativity. By analyzing a company’s historical design data, and keeping private what’s proprietary, BlankAI aids in creating new concepts that align with brand identity and styling cues. Combined with existing Autodesk tools like Alias and VRED, we offer an immersive, collaborative design experience, bridging the gap between ideation and final product development. Efficient person-to-person, and discipline-to-discipline collaboration, with technology like BlankAI at the fingertips of people whose job it will accelerate, is what we provide.

We offer similar, AI-powered functionality in our software used for such varied tasks as creating complex project schedules and laying out a new housing development so each home’s climate is optimized for human comfort, receiving optimal sunlight and minimal wind.

Are there additional costs for the user?

Depending on the specific AI capability you’re interested in, some do incur additional charges, but many are included at no additional cost in our software. A great example is the Automated Drawings capability that is included in Autodesk Fusion and accessible to all users. It seems ridiculous, but after a designer has created a 3D model of a part or assembly, the process of creating 2D projections of the part or components is a laborious and time-consuming process. Automated Drawings solves this by automating the creation of 2D images and laying out of the drawings for each component in a model, sensibly placing sheet metal flat patterns and bend tables and parts lists and balloons for assemblies on the page.

Beyond that, Fusion offers extensions for simulation and generative design, adding more AI-powered features, that users can subscribe to. With this offering, every user gets the AI capabilities they need. Looking at the bigger picture of how we will embed AI capabilities into our offering and how they will be priced in the future, we are still exploring the right path forward. We are doing this in close partnership with our most trusted customers.

How is AI implemented by Autodesk at the customer?

Our customers are using AI features in our products in numerous ways, across all the industries we serve, from architecture, engineering, construction and operations (AECO), to media and entertainment to design and manufacturing. If we take a closer look at generative design AI, that we introduced for Fusion over six years ago, we see that it is used by customers across all industries today. For instance, automotive customers like Toyota use generative design to optimize seat frames. Or customers like Airbus make cabin walls in airplanes lighter and thus air travel more sustainable. With new features now available, such as automated modeling, automated toolpaths and drawings, we extend these capabilities even further for our customers to utilize. What is important to note, though, is that AI is never used on its own. At Autodesk, we see AI as part of a computation service pipeline that uses a mix of technologies to deliver the right experience, at the right time, to the right customer.

Are there any special hardware requirements?

Since Autodesk AI is included standard in the Autodesk Design & Make platform, in many of our desktop and cloud products such as AutoCAD, Maya, Fusion and Forma, system requirements may vary. Thanks to the cloud-connection, data is centralized, accessible on demand, and lives very close to the compute power that enables AI. So, for instance, the AI capabilities available in Autodesk Fusion do not require special hardware or computing capabilities. And we are constantly developing and supporting additional AI-supported workflows, that, when released, are available to users directly.

How can AI support error detection and optimization, such as in the automation of design processes?

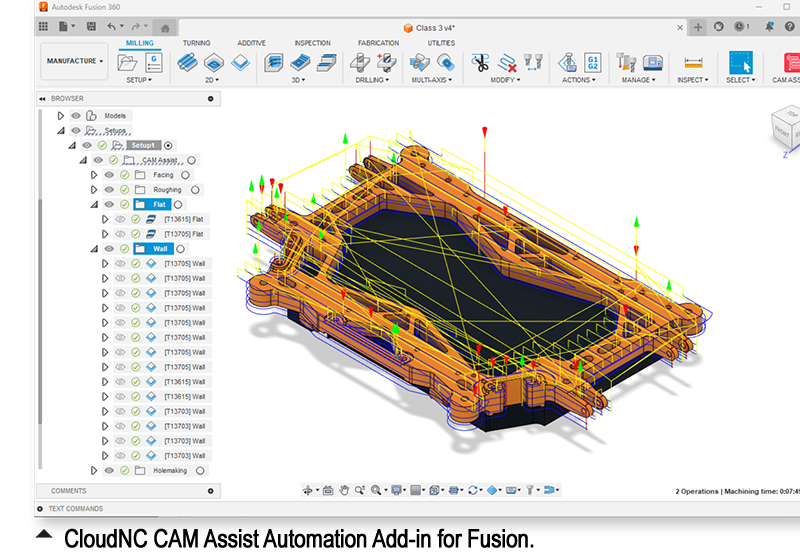

As consumers continue to demand higher-quality products at lower prices, the need for technological innovation is clear. AI is revolutionizing manufacturing, significantly altering product design, development, and production processes. At Autodesk, we blend AI with deterministic algorithms to generate precise output. For instance, the CloudNC CAM Assist Automation Add-in for Fusion translates 3D models of 3-axis components into machining strategies in seconds. It acts as a co-pilot, helping users automate repetitive CAM programming tasks. Strategies and estimations that might have once taken hours or days to develop are now available almost immediately.

Which database is accessed? Internally? Globally (web)?

Since Autodesk AI powers workflows and capabilities across a wide breadth of Autodesk software and the Autodesk Platform, the databases accessed vary. There are Autodesk AI use cases that analyze project data to offer predictive insights. Other use cases augment creative exploration and problem-solving. Others automate repetitive work.

How can it be ensured that the search results (e.g. data used for further design or manufacturing processes, design proposals or parts to be used) do not infringe any rights (IPP)?

Trust in AI is key. At Autodesk, we are committed to strong governance practices to protect personal data and customers’ intellectual property. We’re equally committed to responsible testing and monitoring throughout AI development and use to mitigate or avoid instances where our AI services may perpetuate biases, amplify social challenges, or lead to new avenues of risk. To make sure we fulfill these commitments, we recently hired our first Chief Trust Officer, Sebastian Goodwin, who brings more than 20 years of experience in effectively measuring and managing cyber risk into the company. Of course, we also recognize that there are still many uncertainties surrounding the topic of AI regulation, and there are no easy answers yet. We are working closely with our customers to get it right.

How can AI support data management (PDM)?

As a first step, AI can probably help with simple but time-consuming PDM tasks, such as setting up a tenant, users, and permission rights based on a natural language prompt and a spreadsheet of users. In the long run, the Fusion industry cloud will integrate CAD, CAM, CAE, PCB design, data management (PLM, PDM), MES, and more into one unified experience, enabling advanced automation, AI capabilities, and streamlining of workflows. The Autodesk Fusion industry cloud will provide a single source of project data across organizations and supply chains through the Autodesk Data Model. By ensuring everyone has access to the same data, customers can eliminate repetitive tasks and processes, accelerate productivity, and provide critical real-time insights about product development and business operations.

How can AI support data analysis? What are the advantages for designers?

A general example of AI in data analysis is time-series data that is streamed from machines on the shop floor. In this use case, AI can analyze vast quantities of data, looking for patterns and finding efficiency gaps. A more specific use case in context of design for 3D printing is 1000 Kelvin´s AI co-pilot AMAIZE. With the AMAIZE add-in for Fusion, users upload their additive toolpath data, then the tool offers predictions and suggestions to address build process-related issues before printing. Users can visualize the prints and issues in both 2D and 3D for comprehensive insight. This helps both designers and manufacturers to 3D print metal parts with confidence the first time.

How can AI support the various phases of product development, such as idea generation, simulation and design? Can the benefits be quantified? Is there an ROI?

When we take a closer look at our roadmap for Autodesk Fusion in the year ahead, we see AI working alongside our users, like an assistant, to ease otherwise time-consuming tasks and help get them where they want to be faster. We will continue to make advancements that provide users with a seamless CAD/CAM experience. One example of how we are aiming to do this is through our investment in creating material-aware setups and associated tool presets that help you automate your workflows and save time in the process.

An example of how we’re considering manufacturing automation is our development of automated threading. This feature will enable the transfer of threading data between the Design and Manufacturing workspaces. So, when a thread is created in the Design workspace, the information about the thread can also be accessed in the Manufacturing workspace. This means a user will be able to automate their threading process, accommodate deviations from standard procedures, when necessary, avoid manual threading calculations, and easily access and comprehend your threading data across workspaces.

What risks does Autodesk see in the use of AI?

AI has the potential to collaborate with human stewards to solve massive problems and unlock productivity and innovation. We’re already seeing AI used to address real-world issues such as the housing crisis and extreme weather events. We absolutely need guardrails and regulation, but we must ensure that we are still enabling good AI to fulfill its potential while curtailing bad AI’s ability to do harm. In order to do that, we need to bring in the experts: computer scientists, engineers and yes, even big tech. All of these groups have an intimate understanding of AI that most regulators simply do not possess. We need closer collaboration between the public and private sectors to inform lawmakers of the best approaches to top-of-mind issues. The bottom line for companies is: Can they trust our AI tools? And, will they reduce costs?

What other AI functionalities are already conceivable today? (“Looking to the future”)

There are exciting possibilities on the horizon. For instance, planning a factory with the help of generative AI, and optimizing the planning process with digital twin data.

What other AI functionalities has Autodesk already planned?

An important milestone on our path to generative factory planning is the acquisition of FlexSim, adding factory simulation and operational efficiency analysis to our factory design tools. A digital representation of a factory is an environment where you can plan, simulate, and control operations to accurately predict performance, forecast energy consumption and emissions, analyze safety, and measure equipment utilization. FlexSim brings all these capabilities, enabling more informed decisions sooner, helping meet production targets with precision, and reducing time to market and costly inventory.

What other key aspects do you see regarding AI in design and manufacturing?

Another important aspect in the advent of AI is business process orchestration. AI can be used to connect business processes holistically, not just automate distinct tasks. In context of drawing automation, this leads to the thought: Why should we keep associative drawing data within 3D models, when we can use AI to create drawings instantly, whenever you need them? There are exciting capabilities to be developed for designers and makers every where.