ENHANCING THE TRANSPORT AND LOGISTICS LANDSCAPE

As part of the AMP-funded project, InsAIght, the Fraunhofer Innovation Platform for Advanced Manufacturing at the University of Twente (FIP-AM@UT) collaborated with CAPE Groep and Farm Trans to investigate the possibilities of using an Artificial Intelligence (AI) scheduler for dock slot planning operations. This is a next step to create smarter, more efficient, and integrated operations across systems within the logistics sector. Both CAPE Groep and Farm Trans are experts in the logistics sector.

CAPE Groep has developed the expertise to design and develop user-friendly systems focused on optimising company operations and reduce operation costs. For almost 25 years, CAPE Groep has offered customised software applications to clients in transport & logistics, supply chain, (smart) construction, and agrifood.

Farm Trans, a logistics service provider that undertakes various logistics operations of its customers in the sector, has partnered with CAPE Groep to respond agilely to changes in market demand and continuously improve customer service. Farm Trans, envisioning to incorporate AI in their processes, has selected the process to integrate with AI: dock slot planning.

AI in action

In the fast-paced world of logistics solutions, developing smart systems is a key factor in unleashing the full power of AI. The possibilities for AI have been expanding over the past years across industries and sectors. Applying AI technologies to assist existing jobs has the potential to solve some of the manufacturing and logistics challenges faced by companies however, it may also face reluctance from employees to embrace a new technology.

With the seemingly never-ending possibilities of AI, difficulties arise in scoping projects and finding the correct focus in applying this new powerful technology. By collaborating with pioneers in the AI field, such as FIP-AM@UT and companies in the transport & logistics branch, the bridge has been built between AI technology and business processes.

For supply chain scheduling, AI offers enormous automation potential to become a self-learning tool for employees. By harnessing the vast amount of data generated, AI can provide data-based input for the complex decision-making processes in transport & logistics.

InsAIght for decisionmaking

An AMP-subsidised collaboration between CAPE Groep and FIP-AM@UT led to the project InsAIght, focused on designing and developing an AI-assistant to support employees in logistic planning for logistics company Farm Trans.

The aim is to make the dock planning operation more efficient, effective, and sustainable. The smart technologies, advanced data processing algorithms, and comprehensive AI knowledge provided by CAPE Groep and FIP-AM@ UT can contribute to ensure that logistic processes are carried out faster, more flexibly and with higher performance in dynamic and turbulent environments.

The team, which specialises in the beneficial use of AI algorithms and optimisation techniques, has offered flexible and easy-to-implement solutions through the InsAIght project. Combining the different specialisations of the team has led to a solution that could be easily used within the low-code application landscape of Farm Trans, while maintaining a generic approach to reuse the knowledge in future endeavours.

Use Case

The foundation of the project lies in a thorough understanding of real-world scheduling challenges. This phase was initiated with an in-depth discussion with a Farm Trans expert in truck scheduling, the conversation helped to define the scope of the use case: AI-based scheduling. Through collaborative brainstorming, several potential cases were identified. The case that provided the most business value was improving the planning of the docks at one of Farm Trans’ warehouses because of the dynamics and fluctuations within that process.

Following this case description, the solution focuses on scheduling trucks to predefined time slots for the following day, with three primary objectives:

Minimise the number of unscheduled trips

Ensure fair distribution of trips across slot bookings

Optimise scheduling based on truck tardiness predictions

Key parameters of the scheduling system include:

Scheduling is done one day in advance

Trips are scheduled and a trip may consist of multiple orders

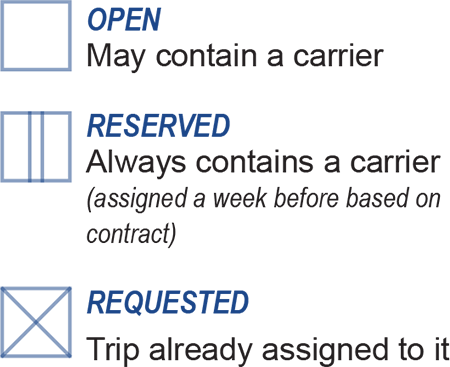

Slot bookings have three possible statuses:

Data collection & analysis

Based on the available data, it became clear that to improve the current scheduling performance is to consider truck tardiness. By accurately predicting how punctual a truck will be at the dock, a more realistic and efficient schedule can be created. This unique approach allows for fine-tune the scheduling process based on real-world variables, resulting in smoother operations and reduced idle time.

The model

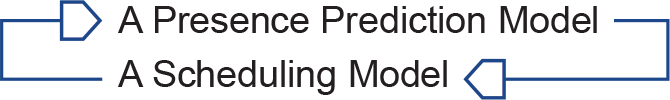

The solution consists of two interconnected parts:

These models were developed using historical dock truck data, including information about loads and truck capacities. By analysing patterns in past arrivals, informed predictions can be about future truck punctuality, allowing for more accurate scheduling.

The scheduling model is built upon historical human scheduling data, incorporating the expertise of experienced schedulers while enhancing it with AI capabilities.

Results

After extensive testing and validation, several key decisions needed to be made regarding the models:

- For presence prediction, a Deep Learning method outperformed models built with Random Forest algorithms. This choice allows for more nuanced and accurate predictions of truck arrival times.

- For the scheduling model, a thorough cost/performance comparison was made between Mixed Integer Programming (MIP) solvers and a novel algorithm developed by the team. Ultimately, the team chose the proprietary algorithm due to its superior performance and adaptability to the specific use case.

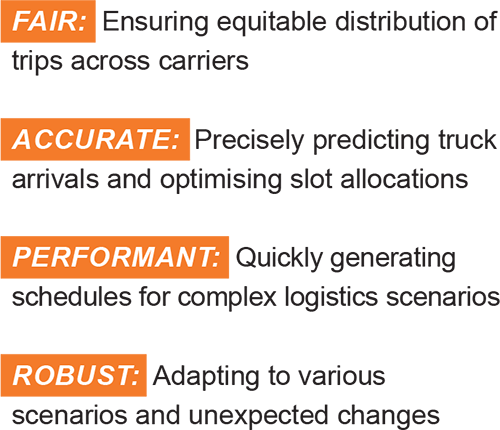

The combination of these two models resulted in a scheduling algorithm that is:

Next steps

After successfully concluding the project, the AI scheduler is implemented as a beta feature in Farm Trans slot booking application. Farm Trans planners are currently working with the AI scheduler alongside their regular planning, to compare results.

In a future project, human input will be incorporated in the AI scheduler to enhance the performance and to stimulate the self-learning capabilities of the model.