SHELTERSUIT FOUNDATION:

BECAUSE EVERYONE DESERVES SHELTER, WARMTH, AND DIGNITY

Although we live in the Netherlands, a relatively rich first world country, there are still homeless people freezing to death on the streets. In Enschede in 2014, Bas Timmer’s best friend’s father died of hypothermia. This shocked Bas into taking action. Already running his own clothing line, Bas was uniquely qualified to design a product that could help prevent homeless people from freezing to death. The Sheltersuit was born, immediately offering warmth, shelter, and dignity to the homeless.

Sheltersuit was founded and established in Enschede eight years ago, producing products that offer an immediate, short-term solution to a long-term global problem. They have now expanded their operations to Cape Town and New York, and plans are underway for the establishment of Sheltersuit in the United Kingdom.

The organisation: Sheltersuit Foundation

Sheltersuit was founded by Bas Timmer in 2014, with the aim of giving back to society. Youp Meek, Partnership Manager at Sheltersuit, explains, “Bas struggled with the dilemma of selling upmarket clothing on the one hand, while on the other, he recognised that many people throughout the world have no money at all to buy warm clothes and are therefore at risk of hypothermia. When the homeless father of his best friend was frozen to death, Bas came up with the Sheltersuit: a jacket with a zippable sleeping bag.”

Sheltersuit is an organisation with clear goals. Firstly, to produce responsible and sustainable clothing with little impact on our planet and huge impact on end-users. Secondly, as much as possible, they collaborate with local suppliers. Sheltersuits are produced locally, often by former refugees and also disenfranchised people who have struggled with access to the labour market. The suits are distributed through humanitarian organisations, who are well-placed to know the needs of their communities and possess the infrastructure to ensure seamless distribution.

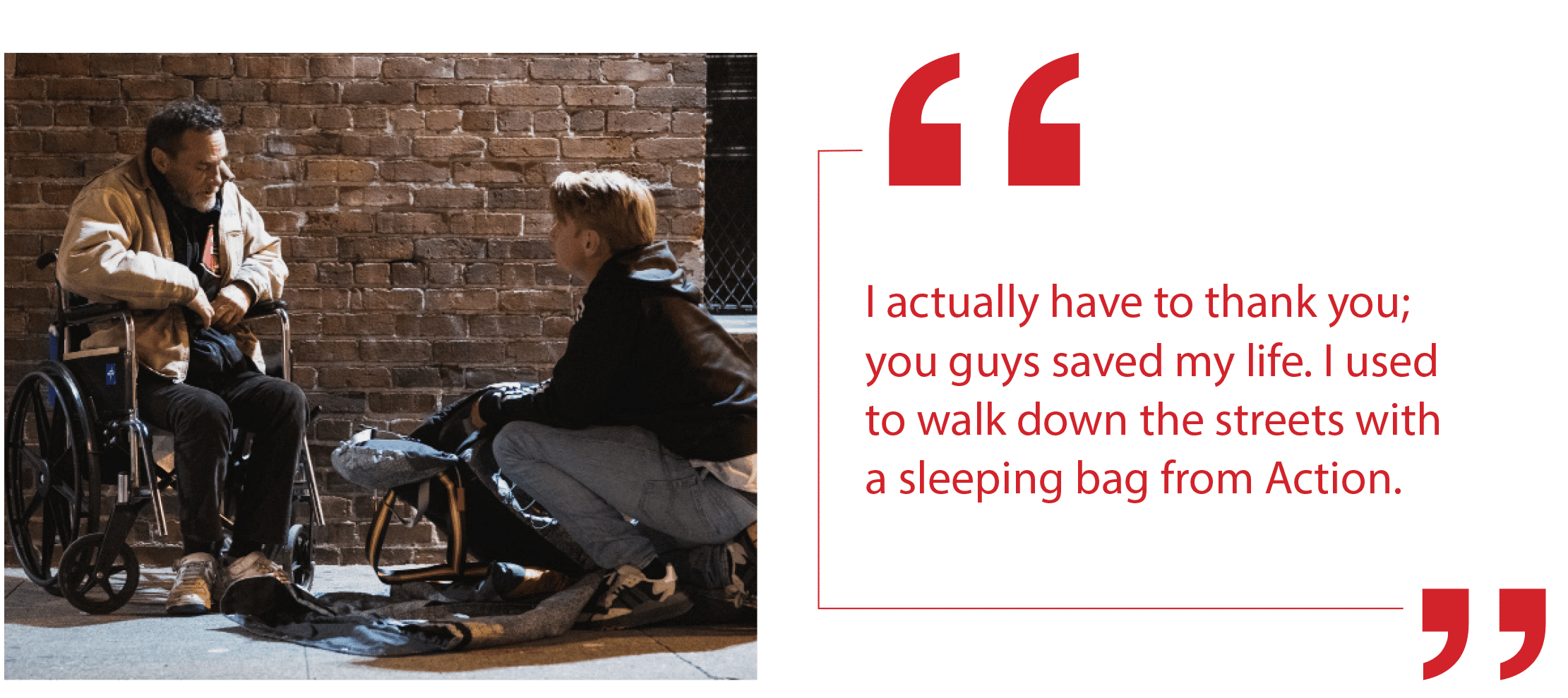

The act of issuing a Sheltersuit forms a dual purpose. It allows social workers to more readily come in contact with homeless people, making it less likely that these people will slip through the cracks unnoticed. Then, as this moment of contact increases, so too does the homeless person’s willingness to accept help. Youp gives an example: “In January, we went to Rotterdam to hand out suits through a humanitarian organisation. One of the volunteers there came to us and said: “I actually have to thank you; you guys saved my life. I used to walk down the streets with a sleeping bag from Action. I didn’t want to hear anything about the homeless shelter. Then I met someone from this shelter who said, “If you come with me, you’ll get a cup of coffee and something warm.- He went to the homeless shelter and spoke to the people there and was given a Sheltersuit. For the next three days, he slept on the streets in his Sheltersuit. He felt warm and safe, feelings he was not accustomed to having. He decided to work as an experienced volunteer at that homeless shelter himself. He also started sleeping there, and last summer, we had a housewarming, because he became eligible for Housing First – a Rotterdam housing organisation for homeless people, and he was allocated his own place to live. It is stories like this that energise us, encouraging us to continue the work we have started. ”

The products

A Sheltersuit offers shelter and warmth to the homeless in colder climates. It is a windproof and waterproof jacket with a zipper at the bottom, to which a sleeping bag can be attached. The hood protects the face from rain and streetlights and allows people to lie relatively covered.

There is also a variant for warmer climates: the Shelterbag. This is basically a single-person tent with a sleeping mat in it. Also the Shelterbag features a large hood, which is designed to cover the head. The Shelterbag is lighter in weight than the suit, and therefore easier to carry for those who move a lot.

The production process

The Sheltersuit Foundation has three pillars:

- Repurpose for purpose: upcycling residual material

- Opportunities and development: Creating new jobs for people with a distance to the labour market, like former refugees

- Sharing shelter: Providing warmth, because everyone deserves that

The products are made of residual materials from donations by high-end, often local, suppliers. “The willingness to donate is great; its a big problem its a big problem that they’re eager to help solve.”

The Sheltersuit production process consists of approximately 120 steps. The first step involves cutting the pattern for the outer layer, cutting about 250 layers at once with a hand-cutting machine. After that, the lining is cut. Then the suit goes into production. The production process consists of seven to nine stations, with everyone simultaneously making a different part of the suit. Finally, the entire suit is assembled, and the snap fasteners are hammered in.

Sheltersuits are available in a range of sizes, from Small to XXL, so they can be sure to have the optimal size for each of their clients. It takes about five hours to make one suit and the cost price is about €300. Having the objective of making their production process more efficient, this cost price will decrease in the future. This year, Sheltersuit will produce a total of 5,000 suits and their goal is to annually make 20,000 suits within five years.

In Enschede, there are currently 18 people employed in the Atelier, with a further 20 volunteers, and nine people in the office. “As our second pillar indicates, the Atelier employs many former refugees, especially from Syria and Eritrea, some of whom are very experienced in the clothing industry.

Having run an Atelier in Damascus for renowned clothing brands, with a production line of 300 employees, our key people know exactly how things are supposed to run. They have considerable experience in the clothing industry, and they are willing to share their skills and knowledge with us. We also help for example young people with a depression, who work with us as a daytime activity. We often find helpers in unusual places. For example, we had a retired woman working with us. She felt lonely and unhappy at home and because sewing was her hobby, she wanted to support us with that.”

The future

Currently, Sheltersuit is almost entirely dependent on donations and gifts. Sometimes these are financial contributions by companies or individuals, sometimes a donation is done in the form of joint distribution of the suits, supported with a financial contribution, or by (temporarily) taking over part of the production free of charge. Another form of income for the foundation is generated by ‘remanufacturing’ a product. Youp explains: “We have, for example, made orange high visibility jackets into sports bags for a construction company. They then bought them back from us and gave them to their staff. A short while later, I received photos of 1,500 employees as they walked into the gym with their reflective orange bags; super cool!”.

In order to generate an extra income stream, Sheltersuit launches a clothing label for end-consumers too. The clothing and accessories will entirely be made from dead stock material.

With regard to technology, Sheltersuit hopes to make the production process even more efficient in the future. First steps in this direction have already been taken, with a recent move to a larger location in the current establishment, Spinnerij Oosterveld in Enschede, and therefore more production capacity. A next step could be an automated cutting machine. On a social level, the people of Sheltersuit hope to contribute to activating the business community to make their production process more sustainable: “In the end, textile industry is one of the most polluting sectors. We hope to motivate companies to take responsibility in combatting pollution.” Furthermore, they hope to become active on every continent, bringing people together to provide everyone of us with a bit of dignity.

Would you like to read more or contribute yourself? https://sheltersuit.com/