END-USER INVOLVEMENT 2.0 IN HUMAN-ROBOT SYSTEMS:

UNLOCKING OVERLOOKED POTENTIAL

In the 1950s, the first industrial robot arm was introduced at General Motors. Now, over seven decades and tons of research and development activities later, the industrial robot became an irreplaceable part of the manufacturing landscape. These robots are operationally excellent, multifunctional, come with increasingly user-friendly software, and can sometimes directly interact with its end-users, such as machine operators or production workers. For long, manufacturers used industrial robots to maximally automate their mass production systems in a pursuit of reducing costs and becoming a fully automated ‘lights out factory’. However, diversifying customer demands, reducing batch sizes, and skyrocketing product variations require manufacturers to drastically increase the flexibility of their production system to remain competitive. To build flexible production systems, high alignment between end-user and machine capabilities is essential. In this article, we explain why end-users are highly important for sustaining human-robot systems and why this urges for more end-user involvement. We introduce the idea of ‘end-user involvement 2.0′, showcase what it could look like, and advice manufacturers how they can closely involve end-users in the design of futureproof human-robot systems.

Given that most industrial robots are as robust as the product variation and issues they are programmed for, end-users are essential to make industrial robots usable for flexible production purposes. Ideally, end-users work closely together with industrial robots, oversee its functioning and product flow, solve unforeseen issues, and reparametrise or reprogram the robot application. To assure that end-users can sustain such a role over time, it is important that working together with industrial robots is perceived as challenging but manageable due to the presence of sufficient decision-making opportunities. It is also important that the robot application triggers end-users to stay alert for the robot’s movements and potential error. If end-users’ work perceptions or alertness are at risk, chances are they get demotivated, stressed, or injured to an extent they cannot sustain the robot application. To safeguard end-users’ work perceptions and alertness, it is important they are closely involved in the design and redesign of their human-robot systems.

At the moment, end-users’ involvement is often limited. In the robot implementations we came across, production managers and engineers dominated the decision-making process. In some instances, end-users had one or a few opportunities to share their ideas, suggestions, and advices with the decision-makers who, in their turn, would implement or ignore the received input. Once the robot applications were decided upon and developed, end-users had limited to no opportunities to change it. This form of end-user involvement, which we refer to as ‘end-user involvement 1.0′, could result in suboptimal work perceptions and alertness if decision-makers misjudge their end-users’ perceptions. It might lead to the design of technically-sound robot applications that, in hindsight, cannot be sustained over time. Here, we present an alternative approach, namely: end-user involvement 2.0.

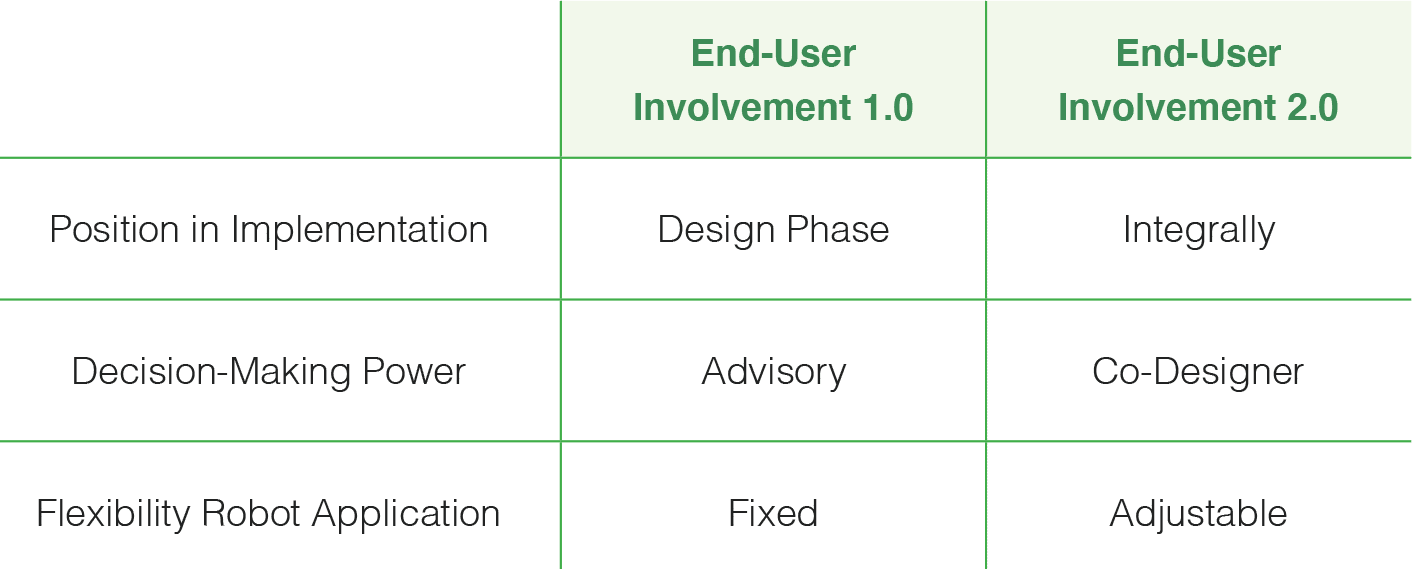

In end-user involvement 2.0, the decision-making power is redistributed to an extent that end-users become co-designers that have a say in the design and redesign of the robot application. They will play an integral part in the robot implementation process and be equipped with the opportunity to adjust and align the robot application with their perceptions. The differences between end-user involvement 1.0 and end-user involvement 2.0 are summarized in table 1. To test if end-users and manufacturers could benefit from more end-user involvement, we ran an experiment.

Table 1: Comparison End-User Involvement 1.0 and End-User Involvement 2.0

Description of the Experiment

A manual workstation and three collaborative workstations were built in a lab environment at Saxion. The collaborative workstations were equipped with a collaborative robot (Universal Robots 5) and had different levels of decision-making opportunities: low, medium, and high. Based on the level of decision-making opportunities, end-users were allowed to design their human-robot task allocation, manipulate the robot’s speed, and adjust the robot’s programs. Demonstrations, work and safety instructions, and workplace assistance were provided in all instances.

Students from regional universities and community colleges joined the experiment. All students had no recent working experiences with robotics. To discover if these end-users would produce better and more sustainable with the robot, we let them execute a number of flexible assembly tasks. They would conduct these tasks at the manual work station first. After that, they conducted the same tasks at one of the collaborative workstations.

We looked into how decision-making opportunities were leveraged, what the design of the human-robot looked like, end-users perceptions (work perceptions and alertness) and performance outcomes (productivity and reliability).

Based on 80 work sessions, we learnt that high end-user involvement could be beneficial for both end-users and manufacturers. Higher levels of end-user involvement enabled end-users to design more efficient task allocations and meet similar productivity outcomes compared to the manual production method – working together with the robot resulted in less product defects across all levels. We also found that higher end-user involvement was beneficial for the end-users’ work perceptions. It prevented end-users from feeling constrained in their decision-making. And although we did not find any work perception improvements, the absolute majority of the end-users agreed that working with the robot would allow them to sustain their work activities better. We did not encounter notable alertness differences across end-user levels, but we did find that higher levels of end-user involvement required more alertness. The robot sometimes functioned too fast or robot applications became unstable when parts of the programs were adjusted incorrectly.

Finally, we noticed that design opportunities were not always used or used constructively. For instance, a third of the end-users who had the opportunity decided not to redistribute the task allocation between the robot and themselves, suppressing personal strengths. Furthermore, only halve of the end-users that we allowed to modify the robot application’s program actually changed it themselves, asked for assistance, or came up with suggestions. Sense of time pressure played an important part in preventing end-users to change the robot application’s program. End-users’ limited working experience with robots could be an alternative explanation and stressed the importance of proper training and workplace support. These lab insights lay a base for how manufacturers can implement end-user involvement 2.0 into their production systems. More information about this experiment can be found in the green box on the previous page.

Manufacturers interested in end-user involvement 2.0 should focus on organizing three important conditions. Firstly, it is important that the end-users structurally receive the (shared) decision-making opportunities and time necessary for affecting the robot application. One way to do this would be to include a few end-users in the project team overseeing the use of the robot. Secondly, the end-users must acquire the necessary knowledge and skills to make informed decisions regarding the robot application. These competencies go beyond maintaining and adjusting the robot application and should also include defending work perceptions and mental alertness. Thirdly, a solid support system must be available to proactively assist end-users in their decision-making. Technical support and safety ques could be provided by engineers while the safeguarding of mental alertness and proper work perceptions could be done by human resource professionals.

To summarize, modern industrial robot technology offers an important opportunity for manufacturers to solve productivity and flexibility issues and remain competitive. In this article, we stressed the importance of end-users to leverage robot technology potential. Lab findings were presented and indicated the added value of end-user involvement 2.0. We hope to have inspired manufacturers with our take on end-user involvement and invite them to follow suit.

“The absolute majority of the end-users agreed that working with the robot would allow them to sustain their work activities better.”

About Research Group (Lectoraat) Employability Transition

Research Group Employability Transition is part of Saxion University of Applied Sciences’ School of Applied Psychology and Human Resource Management. Driven by the mission to prepare workers and organizations (profit, non-profit, and government) for a hightech future, the research group functions as a solid bridge between academia and professional practice. By uniting different fields of expertise in multidisciplinary projects, the research group strives towards practical and evidence-based solutions to sustainably optimize business, technology, work, and human capital. More information about the research group can be found in the article “Technology not good, or bad, or neutral, but always… human!” on page 31 of this magazine issue.