The Power of Generative Design

And its role in the Green Future of Manufacturing

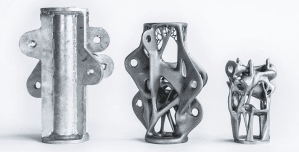

Generative Design is a design tool that enables the exploration of multiple suggested design solutions to an engineering problem. By using unprecedented cloud computing power, Generative Design is able to produce design variations that have not been thought of or were simply not possible to materialise with conventional manufacturing technologies a few decades back. The tool requires input of certain parameters or constraints such as weight limits, geometric constraints, material, and manufacturing methods. Considering these constraints, it creates a set of design solutions, which fulfil these criteria to different levels. It is in that sense different than Topology Optimization. Generative Design aims to display a wide arrange of solutions for a problem, while Topology Optimization focuses on creating a single optimised solution.

The ability to get a multitude of designs from a single tool introduces a new approach to part engineering, which is shifting the design process entirely. Design engineers are being converted from part optimisers to expert parameter curators and skilled design evaluators. The process shift is essential, because GD input parameters are carefully specified to obtain high quality output solutions which need to be then evaluated during the output selection process. For example, two different solutions might meet all specifications. However, one could be slightly stronger, while the other is lighter. Which one would ultimately be the better performer? These key decisions cannot be left to an AI algorithm. In their new role, engineers have to oversee that the design(s) fulfil(s) the specified engineering requirements in the best possible way, while they still have to consider factors such as aesthetics, marketability, and human perception.

With GD it is possible to obtain multiple feasible solutions for diverse manufacturing processes in a single study. Of all the generated solutions, the ones that have the highest weight to performance ratio are often solely producible with Additive Manufacturing. Therefore, even though AM and GD are independent upcoming technologies, pairing GD with Additive Manufacturing might be key for harvesting the full potential of GD and their sustainability benefits.

Some of which are:

- Weight reduction: the design for weight optimisation brings cost and energy savings during transportation and service.

- Parts Consolidation: making multi-part assemblies into single-part products, simplifying the assembly process while reducing the amount and variety of materials used. This means fewer components in the warehouse and a shorter supply chain.

- Waste reduction: When GD parts are made by AM, minimal material is often being used, which reduces waste while allowing for more freedom in design geometry.

- Design exploration: being able to explore not only different shapes, but also materials and production constraints empowered by AI. With the right parameters, solutions are easy to evaluate.

- Faster solutions: by investing time in setting the right parameters, one can obtain an initial solution to a complex design problem that would have otherwise taken days to create conventionally.

Industrial sectors including aerospace, architecture, and construction, are rapidly adopting GD. In these sectors GD has already enabled engineers to produce innovative part designs and to support design decisions based on data, while reducing costs. Since all the output solutions are CAD-ready, the design more quickly goes through stages of evaluation or directly to production, bringing products to market in record time. Generative Design can play a very important role in helping manufacturing companies achieve their sustainability goals and reach higher market value. From a business perspective, some key benefits of using GD are:

- Product differentiation: Creates high performance parts with an exotic look and innovative design that the market has not seen before.

- Expert results: An engineer with limited experience can create a part and gain expertise by testing, evaluating and making relevant decisions while letting AI do the design exploration work.

- Optimised production costs: Saves money and resources by eliminating parts that require several materials or complex manufacturing and assembly steps.

The impact of Generative Design does not solely rely on the design itself, as the title might suggest, but it impacts the entire manufacturing process. In some ways, it could even be argued that “generative manufacturing” would be a more appropriate term. Generative Design, in combination with the implementation of new manufacturing developments, will shape the way manufacturing and production evolve in the coming years.

The 21C hypercar by Czinger is a great example of what can be achieved when pairing Generative Design with Additive Manufacturing technologies. Each component of the 21C has been custom designed, engineered and manufactured for high-performance, stability and ideal weight distribution. For transportation industries, having a good power-to-weight ratio is very important for fuel savings and higher speeds. The incorporation of added functionalities in structural systems, as for example temperature regulation and sound management features within the design, has set a new standard for future design and performance requirements in the automotive industry.

What GD teaches us is that the functional designs, which we currently use, are not necessarily optimal. The optimal designs are yet to be explored. Generative Design is paving the way for making the unimaginable, possible.