Doing Things Differently: Testing materials with low uniform elongation

It is a necessity for metal forming industry to know the material behavior at high plastic deformation in order to perform accurate simulations. A standard practice in industry is to perform a tensile test to get the required material deformation data. Often the material deformations are higher in metal forming processes than what can be achieved by tensile tests. The data from a tensile test is commonly extrapolated using curve fitting techniques. Where the choice of fitting function brings high uncertainty to the accuracy of the results.

Alternative tests such as out of plane bending test, shear test and bulge forming tests offers higher stable deformations than a tensile test. These tests are challenging and complex in order to achieve a reliable and homogeneous deformation state during the test. On the other hand, conventional three point and four point bending test are simple and can be used in a tensile test machine but have issues with local deformations and friction at contact points. Also, the maximum strain is limited by sheet thickness in out of plane bending.

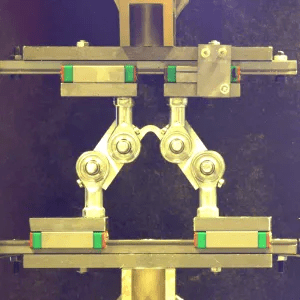

A new and simple bending setup is developed that can be used in a tensile test machine to perform pure bending. The bending happens in-plane of the sheet. The bending deformation can be seen in the figures to the left.

Using image analysis, the bending angle and curvature in the beam can be evaluated. Using the bending angle, specimen geometry and forces measured by the tensile machine, the bending moment can be calculated. The obtained moment–curvature relation can be used to evaluate material behavior in terms of stress–strain relation.

For this purpose an analytical conversion method is used. However, this conversion method is only valid for strains up to 12%. This is because pure bending becomes non-linear and complex at high curvatures. This can be shown by comparing the stress–strain results from the developed bending test with that of a tensile test for a highly ductile Mild steel. It can be seen that the stress–strain curve that results from the bending test deviates from the tensile test at high strain. It is important to note that this limitation in finding the material data at high strains stems from the analytical conversion method, not from the bending test. This method can still be potentially used for materials with very low uniform elongation.

One such material, used in automotive industries is Docol 1400m from SSAB. By comparing a normal tensile test with the results from the bending test, it can e seen that the bending test provides stress–strain data up to 12% strain, while the uniaxial tensile test fails already at 3%. For higher strains a numerical approach can be taken.

In conclusion: with the proposed in-plane bending test, material behavior can be characterized up to high strains, improving the accuracy of the material description and hence improving the accuracy of metal forming simulations.

Full article and references available at: https://doi.org/10.1007/s11340-020-00621-5

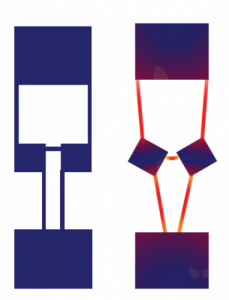

The development started with the idea to perform bending deformation by simply cutting a shape in sheet metal. Such a sample can be clamped in a tensile test machine. Pulling the sample will rotate the two square support parts and the beam in the center will bend.

The first setup, however, did not result in the elongated strains as hoped for. Therefore, it was further optimized to increase the angle of rotation and the bending in the beam. This resulted in more bending on the desired location.

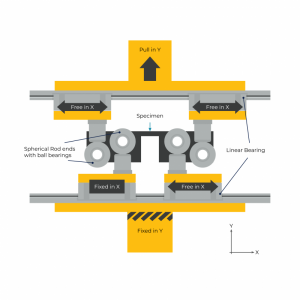

Still, it was found that the optimized sample would not produce enough strain in the beam. Therefore, using linear and roller bearings, a new device was designed. This device can be clamped in a tensile test machine and pulled. The pin-hole interface allows rotation of the two rectangular supports. As a result the beam in the middle deforms with pure bending. This eventually resulted in the appropriate elongation.