Fit for the Future

A Transition Pathway to Circular Manufacturing Systems

The pressure on manufacturing industries to embrace sustainable practices is growing. Depleting natural resources and increasing climate challenges are pushing us toward a circular economy—where products and materials are reused rather than discarded. Circular manufacturing systems (CMS) are central to this transition, and in our recent research, we explored how companies can move toward this future effectively.

Circular manufacturing isn’t just about recycling materials; it’s about creating value by extending the lifecycle of products, components, and materials. The goal is to close the loop—keeping resources in use for as long as necessary. But for companies, this transformation raises important questions: Where do we start? What changes do we need to make? How can we ensure this shift benefits both the planet and our business?

A Three-Level Approach

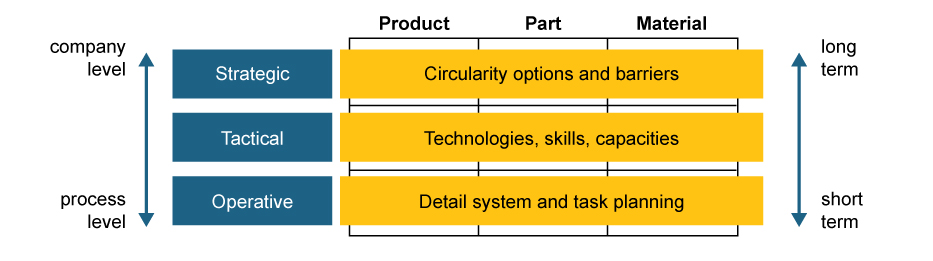

We proposed a framework to address the transition to CMS at three critical levels:

Key Insights from the Study

In collaborating with a global manufacturing company specialising in high-voltage battery packs, we found that remanufacturing components provided the highest potential for impact. It allowed the company to recover significant value while reducing waste and environmental impact. One key finding was the importance of technology in enabling circular systems. Smart sensors, autonomation/autonomous systems, artificial intelligence, and tools like virtual and augmented reality were identified as game-changers for processes like disassembly and remanufacturing. These innovations not only increase efficiency but also make circular systems more economically viable.

The transition to circular manufacturing is not without its challenges. It requires investment, innovation, and a commitment to rethink traditional practices. But the benefits are profound: reduced resource dependency, stronger resilience to supply chain disruptions, and a positive impact on the environment.

As we look to the future, one thing is clear—circular manufacturing is more than a sustainability buzzword. It is a pathway to long-term success for businesses and a healthier planet for all. Through practical tools and thoughtful planning, we believe companies can make this transition and succeed in a circular economy.

Let’s shape a future where manufacturing is not just productive, but regenerative.