INNOVATING FOR A SUSTAINABLE AND INTELLIGENT FUTURE WITH SAXION UNIVERSITY

As society grapples with complex challenges, smart textiles emerge as a promising solution to address these issues through innovative and sustainable approaches. At the forefront of this revolution is Saxion University of Applied Sciences in the Netherlands, where the research group Sustainable & Functional Textiles (SFT) leads the way. Through practice-oriented research, Saxion is developing advanced smart textiles that merge technology with eco-friendly practices, fostering collaborative efforts, overcoming significant challenges, and showcasing real-world applications.

Collaborative Efforts: Saxion’s Partnerships in Smart Textile Research

Collaboration is key to driving innovation in smart textiles, and Saxion excels in forming strategic partnerships with industry leaders, academic institutions, and government bodies. These collaborations facilitate the exchange of knowledge, resources, and expertise, propelling the development of cutting-edge textile solutions. Projects at Saxion often involve multidisciplinary teams, combining the strengths of various fields such as electronics, material science, and design. These joint efforts result in the seamless integration of sensors and actuators into textiles, creating garments that can monitor vital signs, provide therapeutic benefits, and interact with the environment. By working closely with partners, Saxion ensures that its research addresses real-world needs and has practical applications.

Challenges and Future Directions in Smart Textile Research

The field of smart textiles faces several challenges, including scalability, durability, and integration of electronic components. Saxion’s researchers are actively exploring solutions to these issues, focusing on enhancing the robustness and longevity of smart textiles while maintaining their functionality and comfort.

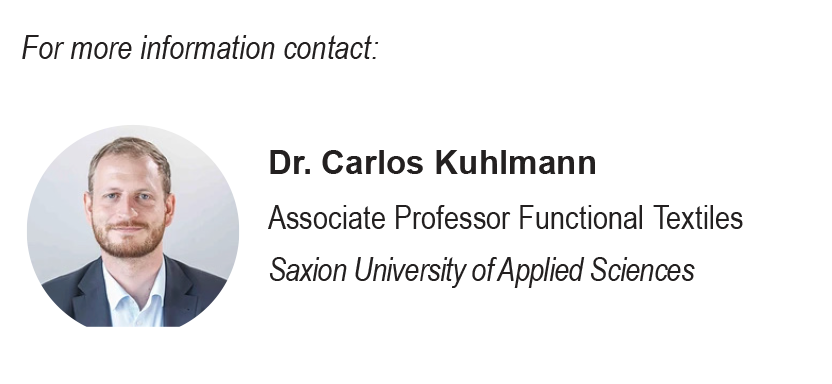

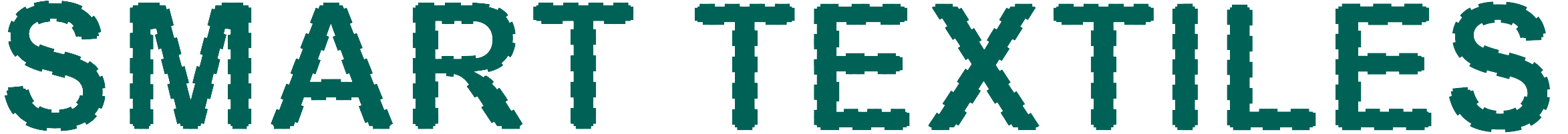

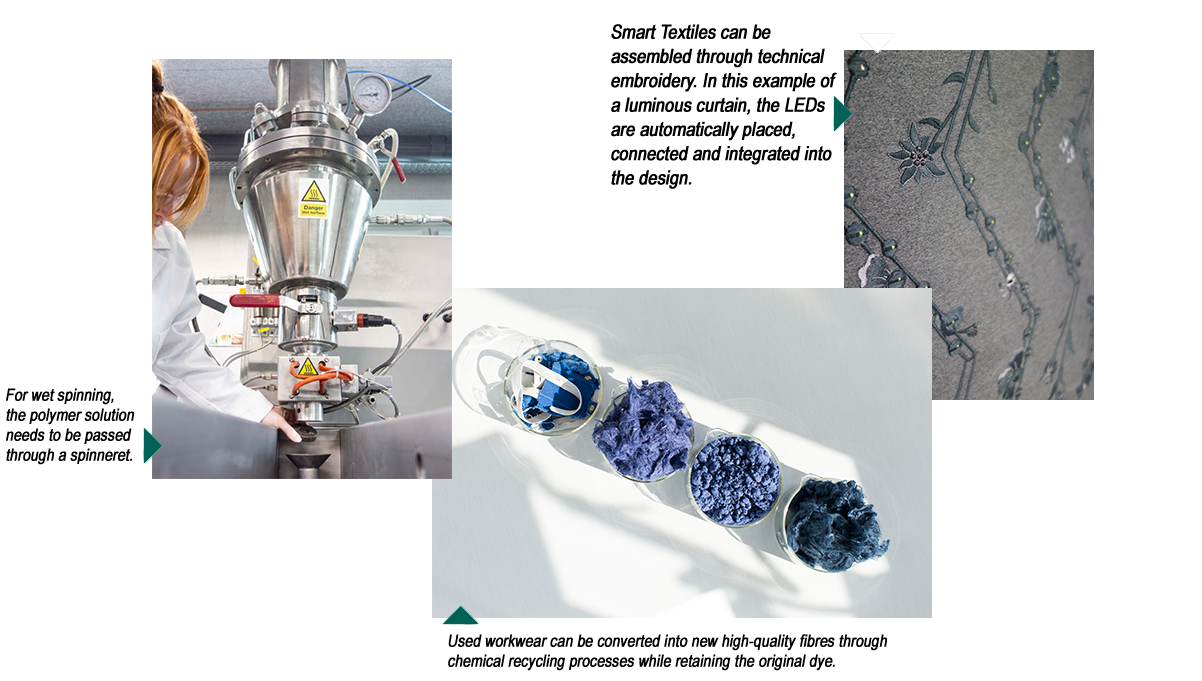

Future directions in Saxion’s research involve advancing the technologies used in textile production, such as knitting, weaving, and technical embroidery. These methods facilitate the incorporation of smart materials into fabrics without compromising their aesthetic or tactile qualities. Additionally, Saxion is investigating new applications for smart textiles in sectors like healthcare, sports, and environmental monitoring, aiming to expand the impact of their innovations.

Towards Sustainable Smart Textiles: Merging Technology with Eco-Friendly Practices

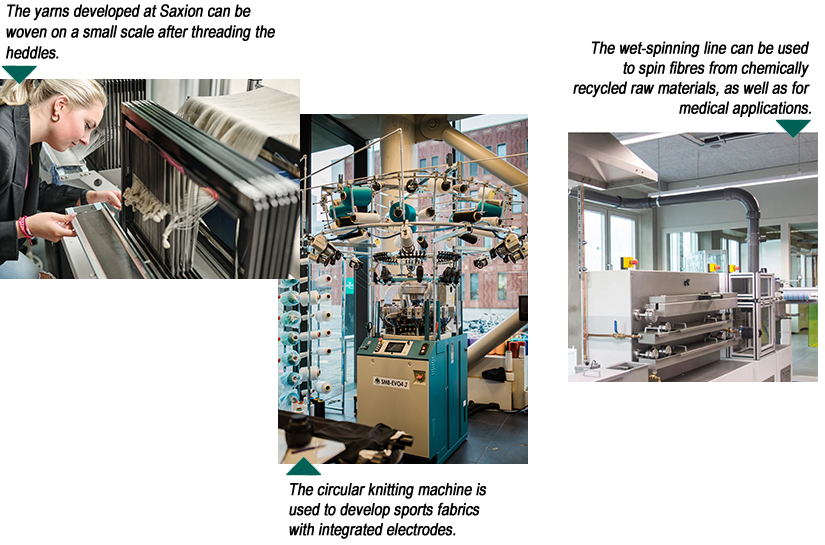

Next to smart textile development, sustainability is a cornerstone of Saxion’s textile research. The university’s Circular Textile Lab is equipped with state-of the-art machinery for recycling, fibre wet-spinning, yarn spinning, weaving, knitting, and confection. This facility enables the rapid prototyping of circular textiles using both recycled and virgin materials. By integrating eco-friendly materials and innovative production methods, Saxion is reducing the environmental impact of textile manufacturing.

Saxion’s research focuses on optimising chemical and mechanical recycling processes, employing spectroscopic analytic tools for textile sorting, and exploring diverse applications of recycled fibres in yarns and fabrics. Rigorous analyses ensure the quality and durability of recycled content, fostering sustainability and bolstering the circular economy within the textile industry. These skills become more and more relevant in the development of innovative smart textile products that take end-of-life solutions into account.

Case Studies

Real-World Applications of Saxion’s Smart Textile Innovations

The practical applications of Saxion’s smart textile research are manifold, demonstrating the transformative potential of these technologies. In healthcare, where healthcare and textiles converge for impactful innovation, smart textiles integrate

sensors for monitoring bodily functions, apply functional coatings, and create intelligent structures for support. These innovations are pivotal for healthier ageing and early disease detection. However, many innovations struggle to transition from concept to implementation due to limited user engagement, high costs, scalability issues, and regulatory constraints like privacy and Medical Device Regulation (MDR).

To address these challenges, a community was established in 2022, bringing together businesses, institutions, universities, and healthcare facilities, supported by Saxion University and University of Twente. This consortium aims to enhance research, development, and education, ultimately increasing the implementation of smart textile innovations.

Key applications include monitoring children’s respiration, providing haptic feedback for training, measuring stress in patients with cognitive impairments, and integrating pressure sensors in socks for diabetics. Additionally, advancements in compression textiles, infusion-stabilising gloves, support stockings, exoskeletons, and textiles in composites are underway. Saxion also focuses on functional surfaces with odour-masking and antibacterial coatings, and thermoreactive materials.

Emphasising sustainability, Saxion promotes the reuse of hospital textiles, alternatives to disposables, textile recycling, and optimised production processes, driving functional textile innovation for a healthier and more sustainable future.

Another compelling application of Saxion’s innovative research lies in the transformation of medical textiles for a circular future. This captivating case study showcases collaborative efforts between Saxion’s research group Sustainable & Functional Textiles, Amsterdam UMC, The Bin, and Van Moer Bedrijfskleding.

In this initiative, the project team explores the concept of rejection to renewal, focusing on shifting from disposables to sustainability. At Amsterdam UMC, a surplus of rejected textiles, including doctor’s coats, nursing uniforms, trousers, polo shirts, and jackets, awaits repurposing. However, finding a suitable option for giving these materials a second life has proven challenging. Driven by their sustainability goals, Amsterdam UMC seeks to unlock the potential of these materials for both internal use within the hospital and external stakeholders.

Van Moer Bedrijfskleding, the supplier of work clothes to the UMC, shares this sustainability vision and aims to enhance their expertise in sustainability and the circular economy. They aspire to integrate these principles into their product offerings for the hospital. Saxion takes the lead in this research, partnering with The Bin, an organisation specialising in facilitating the transition to circular systems.

The project addresses the hospital’s transition from disposable to reusable products. Through meticulous examination, the project team aims to determine the feasibility of creating new products from high-quality rejected textile material (comprising 65/35% polyester/cotton), such as doctor’s coats and nursing uniforms. These repurposed items could potentially replace current disposable products, aligning with the hospital’s sustainability objectives and fostering a circular approach to textile management within healthcare settings.

Shaping the Future: Saxion’s Vision for Smart Textiles

Saxion University of Applied Sciences is at the cutting edge of smart textile research, merging sustainability with technological innovation to create products that address real-world problems. Through collaborative efforts, the university is overcoming significant challenges and paving the way for future advancements in this dynamic field. As Saxion continues to explore new frontiers in smart textiles and textile recycling, the impact of their work will undoubtedly be felt across various sectors, from healthcare and sports to environmental sustainability, shaping a smarter and more sustainable future.