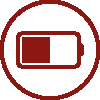

Today, as the world contends with environmental challenges, the European Regional Development Fund (ERDF) is championing an initiative that promises to reshape the future of heavy mobile equipment. The World Class Zero Emission Mobile Equipment project, a collaboration that marries cutting-edge technology with sustainability, aims to create zeroemission vehicles.

Bridging Technology and Sustainability

The World Class Zero Emission Mobile Equipment project is more than just an ambitious endeavor; it represents a vital leap towards addressing the pressing issues of our time—energy transition, digitization, and raw materials scarcity. By focusing on heavy mobile equipment such as the Empty Container Handler (ECH) and the Hooby Narrow Gauge, the project aims to eliminate CO2, NOx, particulate matter, and noise emissions. This not only positions the initiative at the forefront of environmental stewardship but also sets new standards for industrial performance.

Four Pillars of Innovation

In the pursuit of transforming heavy mobile equipment towards a zero-emission future, the World Class Zero Emission Mobile Equipment project stands on four pillars of innovation. These pillars not only guide the project’s objectives but also underscore its commitment to sustainability and technological advancement.

Modular and Scalable Technology

The heart of the project lies in its commitment to developing technology that is both modular and scalable. This approach ensures that innovations can be seamlessly integrated into various types of mobile equipment, broadening the scope and impact of the project. By creating adaptable technology solutions, the project promises widespread applicability and long-term viability.

Revolutionizing the Heavy Mobile Industry

Innovation in the heavy mobile industry is no small feat. The project aims to drive significant advancements, setting new benchmarks for sustainability and efficiency. By leveraging the latest in technology and research, the consortium is poised to redefine industry standards and pave the way for a cleaner future.

Enhancing Battery Circularity

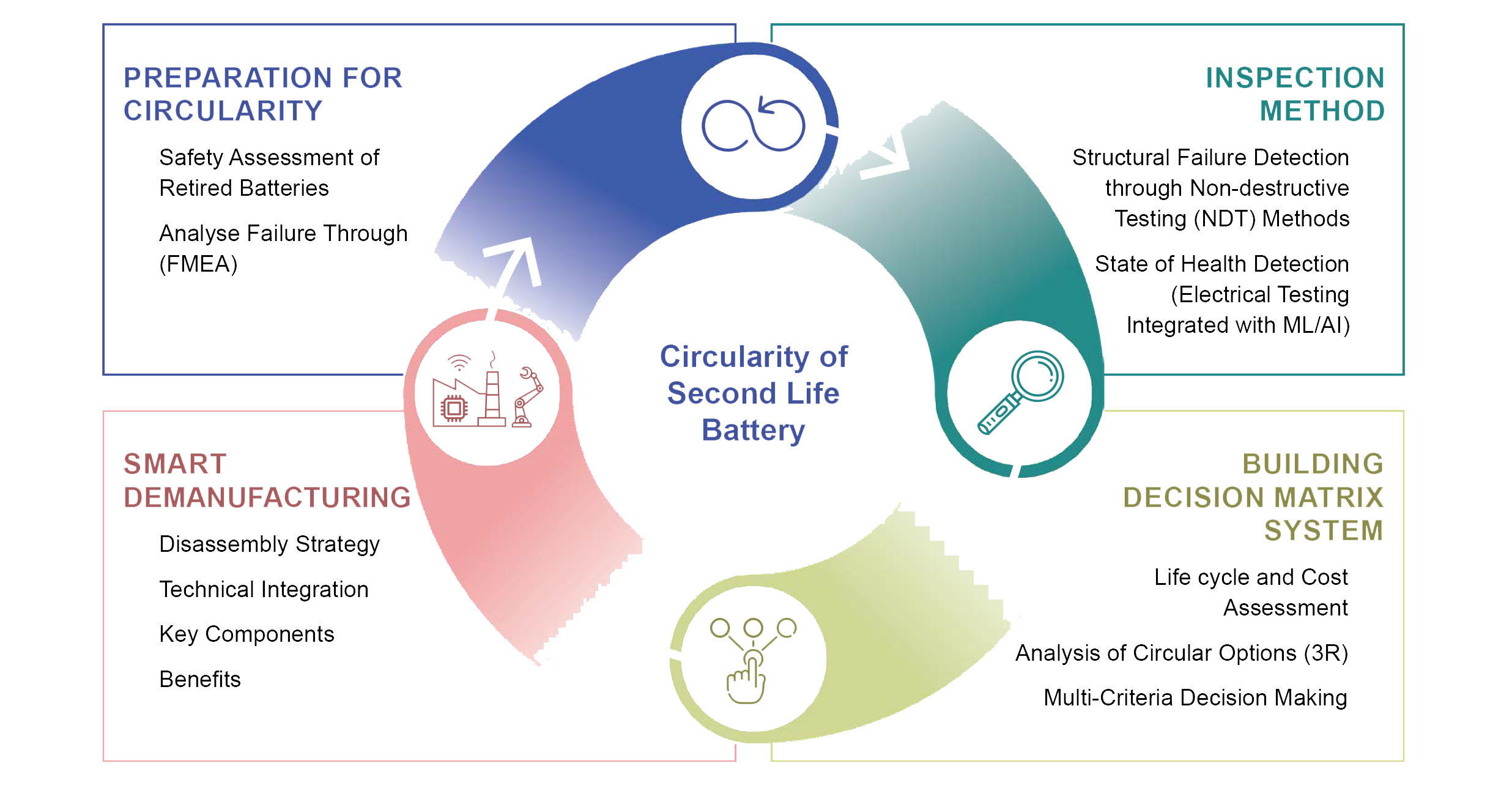

A critical component of the project is the focus on battery circularity. Enhancing

the value chain of battery packs and modules ensures that they are utilized efficiently and recycled responsibly. This not only extends the life cycle of batteries but also reduces the environmental footprint of mobile equipment.

Achieving CO2 Emission Targets

In alignment with Dutch and European environmental goals, the project is dedicated to drastically reducing CO2 emissions. This commitment underscores the initiative’s role in combating climate change and promoting sustainable practices across industries.

University of Twente: The Research Engine

The University of Twente is integral to the success of the World Class Zero Emission Mobile Equipment project. As a leading research institution, the university plays a crucial role in advancing the frontiers of innovation and sustainability in heavy mobile equipment. Their efforts are concentrated on three key areas:

Innovative Research

The university is committed to exploring cutting-edge technologies that enhance the sustainability and efficiency of heavy mobile equipment. By investigating new designs and processes, they aim to develop solutions that are both effective and practical.

Promoting Circularity

Leading the charge in enhancing battery circularity, the University of Twente focuses on ensuring that battery components are reused and recycled responsibly. Their research into the life cycle of batteries helps to minimise waste and maximise the value of materials.

Knowledge Dissemination

Through active engagement and collaboration with industry partners, the university ensures that research findings and best practices are shared within the consortium. This collaborative approach helps to accelerate the implementation of innovative solutions across the industry.

Pioneering Progress: Current Research Status

The World Class Zero Emission Mobile Equipment project has made significant strides across various research areas. The University of Twente has developed a generic Failure Modes and Effects Analysis (FMEA) for lithium-ion batteries, applicable in both ex-situ and in-situ conditions. This FMEA is currently undergoing validation by industrial partners, ensuring that it meets the practical needs of the industry.

To mitigate safety risks associated with retired battery packs, understanding their internal conditions is crucial.

Techniques such as industrial CT scanning and thermal imaging are being tested to detect anomalies of the battery cells. Currently, SOH (State of Health) tests are being conducted on retired batteries at different C-rates to determine their potential for secondary use based on their current state. To streamline this process, machine learning and deep learning models will be deployed for automation.

Smart disassembly initiatives are also underway, focusing on efficiently breaking down battery packs into individual cells. By identifying structural complexities and optimizing disassembly processes, the project aims to streamline the recycling and reuse of battery components. These efforts are essential for enhancing the circularity of batteries and reducing environmental impact.

The Big Picture: Overview of the Research Topic

The Road Ahead

The World Class Zero Emission Mobile Equipment project is more than just a research initiative; it is a blueprint for the future of the heavy mobile industry. By uniting industry leaders and academic institutions, the project aims to set new standards in sustainability and performance. With a clear focus on eliminating harmful emissions and promoting circularity, this initiative not only aligns with European environmental targets but also leads the charge towards a greener, more sustainable future.

Through research, development, and knowledge sharing, the consortium is poised to make a lasting impact on the industry and the environment. The road ahead is challenging, but with the combined expertise and dedication of its partners, the World Class Zero Emission Mobile Equipment project is well on its way to achieving its ambitious goals.