CONVERGENCE IN MANUFACTURING

OLD WAYS OF WORKING NO LONGER WORK: ENTER CONVERGENCE IN MANUFACTURING.

TECHNOLOGY LIKE THE CLOUD AND GENERATIVE DESIGN WILL BRIDGE THE DESIGN-MAKE DIVIDE

More than a century ago, Henry Ford popularized the assembly line, a revolutionary manufacturing idea that enabled mass production. Although that linear approach has worked well, today’s world requires a new stroke of ingenuity: convergence.

Convergence merges design and manufacturing processes, data, and technologies to coordinate workflows across different disciplines. Convergence also helps companies keep pace with increasing consumer demands and accelerate innovation through agile workflows.

What Is Convergence in Manufacturing?

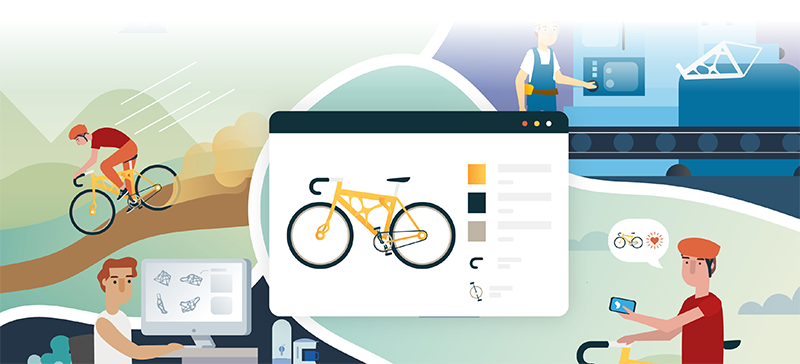

Convergence is the intersection of design and manufacturing. It’s the digital confluence of unrelated technologies, which allows designers, engineers, manufacturers, and machinists to work together from the initial design to the physical product.

Convergence dissolves silos, creating a connected ecosystem where tools and technology produce interoperable data points that foster collaborative workflows. It supports mass production while also enabling customization.

So, what does convergence in manufacturing look like in action? It can take the form of engineers and manufacturing professionals working together in a common data environment in the cloud. Or it can be a generative-design process, where teams collaborate to define functional and performance requirements, using cloud-computing power to find the best geometric solution to a problem.

What Is Driving Convergence in Manufacturing?

Here are several external forces driving convergence.

An Insatiable Demand for Faster Innovation

With a click of a button, people can order almost anything. Consumers want rapid innovation and more customized products than ever before. The old linear process isn’t fast enough to keep up with this demand: Companies must be more agile and more iterative. To do that, they have to converge the process of designing something with the process of making it.

With convergence, companies have the capability of creating something, hitting “print,” and making one-of-a-kind items. Customers can even tap into the process directly, ordering a pair of sneakers they designed themselves or building their dream car.

The Acceleration of Digital Transformation in the Cloud

Manufacturing is an industry with deep roots, where change comes in slow-moving waves. But due to the distributed nature of productdevelopment teams around the world, the pandemic has accelerated digital transformation.

Technologies such as artificial intelligence, robotics, and virtual and augmented reality are fueling the rise of smart factories and laying the foundation for convergence in manufacturing. And a lot of that is possible because of the cloud.

Cloud-based ecosystems are creating data-driven, collaborative environments where unrelated technologies can communicate. As engineers make decisions, they can run real-time simulations in the cloud to determine what will work and what won’t. When General Motors had to improve a seat bracket, it used generative design. The original component was an assembly of eight different parts, each manufactured separately. From 150 different possibilities, the end result is a single-piece part with 40% less mass that’s 20% stronger and meets all safety requirements.

Bicycle-parts manufacturer SRAM supplies another example of closing the gap between design and manufacturing. To design a better crank arm—the part connecting a bike’s pedal to the crankset, converting energy to rotate the chain—SRAM used generative design. The company input the components’ performance needs for varying terrain and ended up halving the weight of the original crank arm. It was also 20% stronger and helped SRAM streamline its overall manufacturing process.

Convergence merges design and manufacturing processes, data, and technologies to coordinate workflows across different disciplines.

Having all processes in the cloud creates a digital thread that maintains data fidelity as a product moves across disciplines over the entire lifecycle.

The Need for a Leaner, More Sustainable Industry

The manufacturing industry has a substantial carbon footprint, accounting for 54% of global energy consumption and 20% of global emissions1. As companies respond to increasing consumer demands, a more connected design-manufacturing process can be better for the planet.

But how does producing more things faster mesh with sustainability? First, companies should understand the total footprint of a product, from raw materials to the recyclability and circularity. Convergence allows engineers to test different design variables—like raw materials—digitally before production begins. Designers can also take a circular approach to determine how products can be recycled, avoiding the landfill.

3 Ways to Promote Manufacturing Convergence

As pressure mounts for companies to do things better, engineers and designers need to be more aware of the downstream implications of every decision. Convergence is gaining steam and opening the market to newer companies—start-ups that aren’t tethered to legacy systems; they go straight to the convergent business model, bypassing other ways of working.

Convergence leads to better outcomes and better products. Here are three ways companies can reap the rewards of this manufacturing model.

Embrace Outside Perspectives

Manufacturers that have been in business for a long time might be resistant to change, arguing, “That’s the way we’ve always done it.” But that tunnel vision limits innovation, stunts growth, and can be the death knell of a company. It’s important to have external perspectives to embrace change. Traditional companies can learn from competitors that operate from a different set of parameters and don’t have the drag of old processes. They’ll move faster, innovate more, and be the disruptors of the industry.

Place Value on Outcomes Instead of Activities

Companies lose productivity and profitability when they focus too much attention on activities(2) without understanding the outcome those activities enable. Instead, companies need to think about why they make things and how they can deliver value. Whether it’s a fitness device or a jet engine, the intrinsic value is not in the effort that goes into building the physical asset but in the experience that object ultimately delivers.

Upskill Workers

As companies rewire their workflows to connect design and manufacturing, they also need to make space for upskilling workers. McKinsey found that 90% of the manufacturing workforce will need new skills(3) in the digitally connected world. Leaders need to train their teams for jobs requiring human ingenuity rather than physical labor. Deloitte(4) predicts careers like digital-twin engineers, smart factory managers, and robotics operators.

As the world grapples with the impacts of the pandemic, manufacturing needs a stabilizing force—a path to greater resilience, stronger supply chains, and a workforce prepared for the digital future. Manufacturing needs convergence.

Sources

1. How manufacturing can thrive in a digital world and lead a sustainable revolution. (2020, February 10).

World Economic Forum. https://www.weforum.org/agenda/2020/01/factories-ofthe-future-innovation-manufacturing/

2. Dolfing, H. (n.d.). Project Inputs, Activities, outputs, Outcomes, impact and results. Henrico Dolfing. https://www.henricodolfing.com/2020/09/project-inputs-outputs-outcomes.html

3. Behrendt, A., De Boer, E., Kasah, T., Koerber, B., Mohr, N., & Richter, G. (2021).

Leveraging industrial IoT and advanced technologies for digital transformation: How to align business, organization, and technology to capture value at scale. McKinsey & Company.

4. Wellener, P., Dollar, B., Manolian, H. A., Monck, L., & Hussain, A. (2019).

The future of work in manufacturing: What will jobs look like in the digital era? Deloitte Insights.