REMANUFACTURING FOR GOOD

EXTENDING COMPONENT LIFE THROUGH HYBRID ADDITIVE MANUFACTURING

The energy sector faces a pressing challenge on how to keep high value components in service for longer without compromising safety, performance or sustainability. Traditional repair and replacement methods often mean scrapping parts that are mostly still functional. This consumes raw materials, energy and time.

Through the EU-funded project “3D Printing Optimised Production” (3DoP, project ID 101083997), f3nice, Valland and Trentino Sviluppo have been demonstrating how hybrid additive manufacturing can be a powerful answer. By combining advanced metal deposition with precision machining, damaged or outdated components can be restored or upgraded while significantly reducing environmental impact.

At the heart of this work is Laser Directed Energy Deposition. In this process a focused laser melts metal powder directly onto a part, rebuilding only the material that is needed. This makes it ideal for repairing and modifying high-value parts.

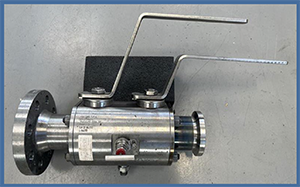

In this project, f3nice supplied recycled stainless steel and nickel-based alloy powders made entirely from scrap metal. Valland contributed by providing complex industrial valve components from its product portfolio. Trentino Sviluppo, operating the PROM Facility, shared advanced hybrid manufacturing capabilities and testing expertise. The work has gone beyond simple repairs, showing that additive techniques can also deliver functional changes to existing parts, avoiding the need for new manufacturing entirely.

Environmental Advantages Proven Through Life Cycle Assessment

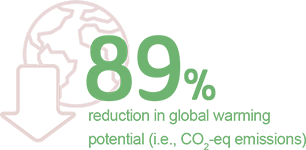

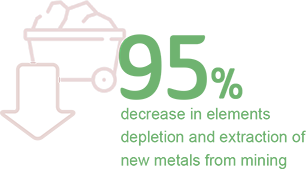

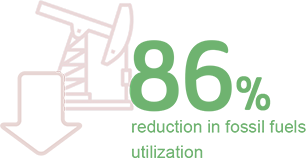

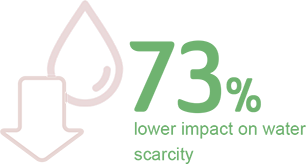

The environmental performance of this remanufacturing route was quantified through a Life Cycle Assessment comparing the hybrid method to conventional replacement. The findings1 were striking:

These savings come largely from avoiding the production of virgin steel and the associated energy intensive processes. Matteo Vanazzi, Chief Technology Officer of f3nice, emphasises that by using recycled metal powder and repairing only what is necessary, valuable materials are kept in use and the environmental cost of maintenance is drastically reduced.

1) Gholamzadeh, S., Cabrioli, M., Vanazzi, M., Giorgini, A., Brambilla, D., Acquistapace, G., Perini, M., & Amirabdollahian, S. (2025). Extending component life through hybrid additive manufacturing: Environmental assessment of a remanufactured valve component. ACTA TECHNICA NAPOCENSIS – Series: Applied Mathematics, Mechanics, and Engineering. (Under publication).

Towards a Future of Remanufacturing

The 3DoP project makes a compelling case for integrating hybrid additive manufacturing into mainstream industrial maintenance. By combining the precision of additive processes with the pragmatism of repair, the approach supports a ReManufacturing for Good mindset that values resources, extends product lifetimes and aligns with circular economy goals.

Trentino Sviluppo played a crucial role in developing and refining process parameters for each material, particularly when working with recycled powders from f3nice. Every stage was guided by the need for strong metallurgical bonding and defect-free deposits.

For Valland, the benefits extend beyond sustainability. Modifying existing components on demand can shorten lead times, reduce inventory needs and offer customers a tailored response without compromising performance or compliance. Gianluca Acquistapace, Additive Manufacturing Manager at Valland, notes that hybrid additive manufacturing is not only a greener way to work, it is also a smarter and more flexible approach to high-value component management.

The message is clear. In many cases the most sustainable part is the one you already have, given a new lease of life through innovation.

Case in Focus: Giving a Valve Flange a Second Life

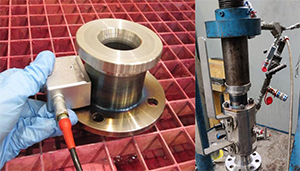

The valve flange modification is a prime example of how hybrid additive manufacturing can deliver both performance and environmental benefits. Instead of manufacturing a new LF2 carbon steel ball valve flange from virgin steel, the team modified the existing part using recycled 316L stainless steel powder from f3nice and Laser Directed Energy Deposition.

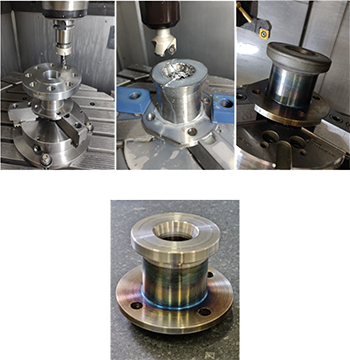

1. CNC milling removed excess material to prepare the flange for deposition

2. Laser Directed Energy Deposition added the new geometry

3. Precision machining brought the part to exact specifications

The remanufactured flange passed dye penetrant, ultrasonic, dimensional and pressure tests, achieving the same operational standards as a new component. This case shows how a targeted hybrid additive manufacturing approach can extend component life, reduce waste and support circular economy goals without sacrificing quality or safety.

This work was carried out within the 3DoP project funded by the European Community under the Vanguard Initiative Proposal

ID 101083997. The views expressed are those of the authors and do not necessarily reflect those of the European Commission.

About the Partners