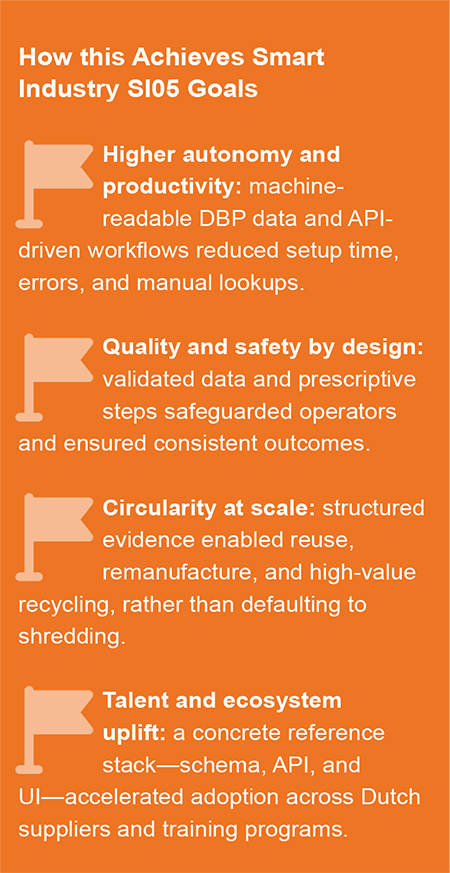

ENABLING SAFE AND EFFICIENT BATTERY DISASSEMBLY THROUGH DIGITAL BATTERY PASSPORT

Driving the Future: NXTGEN Hightech and the Smart Industry Transformation

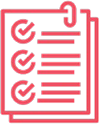

As industries worldwide face mounting pressure to innovate, digitize, and decarbonize, the Netherlands is taking a bold step forward through the NXTGEN Hightech program. At the heart of this initiative lies Smart Industry (SI05) a sub-theme dedicated to paving the way for the factories of the future! Factories are becoming more autonomous, personnel more productive, and machines smarter. Production processes are becoming more efficient, and together we are developing the skills needed to move the Netherlands forward in digitalization.

Bridging Technology and Society

Smart Industry is not simply about automating factories, but it is about creating factories of the future production systems that adapt quickly, reduce waste, and deliver higher quality with fewer resources. At a time when the Netherlands and Europe face a shortage of skilled workers, Smart Industry provides digital tools and platforms that make supply chains transparent and resilient. This includes digital twins, real-time feedback systems, and standards for data interoperability. Together, these ensure that every step of the value chain from design to certification flows seamlessly.

The focus within Smart Industry05 is on integrating advanced digital tools and Industry 4.0 standards to make production systems more autonomous. Common components such as digital blueprints and architectures for autonomous manufacturing systems are being developed. The project aims to enhance flexibility and enable faultless production of complex products in small series. This will be achieved through automatic configuration and programming of production processes, including logistics, which will eliminate setup times and ensure continuous quality. The results will serve as national standards to strengthen the competitive position of Dutch companies.

University of Twente’s Blueprint for Digital, Safe, and Efficient Battery Disassembly

As Dutch industry races toward smarter, cleaner manufacturing, NXTGEN Hightech and its Smart Industry SI05 sub-theme set the stage for adaptive and sustainable factories. Within this vision, the University of Twente (UT) is charting a practical path: turning the Digital Battery Passport (DBP) from a compliance concept into a working engine for safe, efficient disassembly of lithium-ion battery packs and for truly circular manufacturing system.

Bridging Data and Disassembly

UT is not just defining what a DBP is; it is showing how to use it on the shop floor and in second life applications. The idea is simple but powerful: if every battery carries trustworthy, structured, and connected data, then robots, technicians, and decision systems can perform disassembly faster, safer, and with fewer errors. That is the promise of Smart Industry, a data-driven autonomy that cuts waste, increase safety, shortens setup times, and boosts quality.

The Pillars of UT’s DBP Initiative

1) A Proposed DBP Structure that Industry Can Use

UT has design a production-grade data model for the DBP, rooted in literature, current industrial practices and the guidelines by European Union whose structure is complete, interoperable, and future-proof.

Data domains: materials and chemistry, cell/module/pack design, manufacturing history, test & diagnostics, usage/ SoX (SoH/SoC/DoD), thermal & safety events, service/repair, logistics, and end-of-life outcomes.

Relational integrity: clear foreign key links across lifecycle stages (e.g., material → CAM → cell → module → pack) to preserve traceability.

Typed and validated fields: strong data types (Enums for chemistries and formats, numeric ranges for voltages/ capacity, timestamps, geotags) and validation rules that make the DBP reliable enough for automation.

Access and governance: roles, permissions, and audit trails to meet safety, IP, and regulatory needs.

2) A Working Prototype: Dashboard, Database, and Backend API

To move from research to real-world application, UT developed a working prototype that integrates a relational database, backend API, and operator dashboard into one coherent system. The database, implemented in PostgreSQL, stores lifecycle data in structured tables (e.g., material extraction, CAM, Cell manufacturing, module assembly, pack assembly), preserving traceability through foreign key relationships. The backend API, built in Fast API, exposes secure, well-documented endpoints (e.g., /battery/{id}/material, /battery/{id}/ modules), enabling role-based access for OEMs, remanufacturers, and recyclers. This ensures that authenticated actors can update or retrieve only the information relevant to their lifecycle stage. Finally, the dashboard provides a user-friendly interface where operators can access dynamic first-life data such as SoC/SoH trends, alongside stage-specific details like connector types, fastener specifications, isolation steps, hazard warnings, and torque sequences.

As illustrated in the figure, this prototype connects database queries, API responses, and dashboard visualization, enabling safe, efficient, and traceable disassembly and repurposing operations.

3) From Data to Action: Safe & Efficient Disassembly

UT’s core contribution lies in transforming DBP data into concrete decisions and operator-level actions. The system is designed around a centrally supervised database, where each lifecycle stage has restricted access and OEMs can authenticate to update only their relevant records. Once accessed through the dashboard, the prototype prioritizes safety by generating automatic lock-out/tag-out prompts, isolation steps, and thermal risk alerts, tailored to the specific pack configuration.

It also enables procedure generation, creating dynamic disassembly workflows that detail ordered steps, required tools, torque specifications, force thresholds, and PPE requirements directly derived from the pack’s specification, joining methods, and recorded events. In parallel, a decision support layer leverages rules and ML-ready signals to suggest optimal pathways such as repair, module swap, cell harvesting, or direct recycling, complete with rationale, time/cost estimates, and expected yield.

Finally, the system closes the loop through feedback capture, recording real disassembly outcomes (e.g., stripped fasteners, damaged tabs, time per step) to refine procedures and continuously update the DBP for subsequent life cycles. As illustrated in the figure 2, DBP data flows seamlessly from lifecycle records into actionable, pack-specific disassembly instructions, making the passport a driver of both safety and circularity.

The Road Ahead

By delivering a rigorous DBP structure and a hands-on prototype that turns data into safe, efficient disassembly, UT has provided Smart Industry SI05 with a tangible lever: data-driven circular manufacturing system. The prototype, with embedded smart industry capabilities, can plug directly into autonomous factory concepts. Digital twins and traceability functions allowed DBP data to feed simulations and quality records for certification and compliance.

Crucially, the prototype demonstrates how batteries can be disassembled safely and efficiently by combining essential data from different lifecycle stages with dynamic information such as battery structural design, state-of-health, usage history, and safety events. This ensures operators no longer rely on incomplete manuals or guesswork but instead have access to precise connector types, fastener specifications, hazard warnings, and live diagnostics at the moment of intervention. In this way, the DBP evolves beyond a compliance instrument into a practical enabler of safe, consistent, and cost-effective circular practices.

The Digital Battery Passport is more than a regulatory requirement. It acts as a catalyst for safer, smarter, and more sustainable manufacturing. By connecting data across the battery lifecycle and turning it into practical steps, the University of Twente’s prototype shows how circularity can become part of everyday industrial practice. For the Dutch industry, this means greater resilience, new opportunities in remanufacturing, and a stronger role in the global transition to clean energy. As Smart Industry SI05 advances, the DBP offers a blueprint for transforming challenges to advantages.